ASTM A240 TP304H Stainless Steel Perforated Sheet

Content

304h machine part

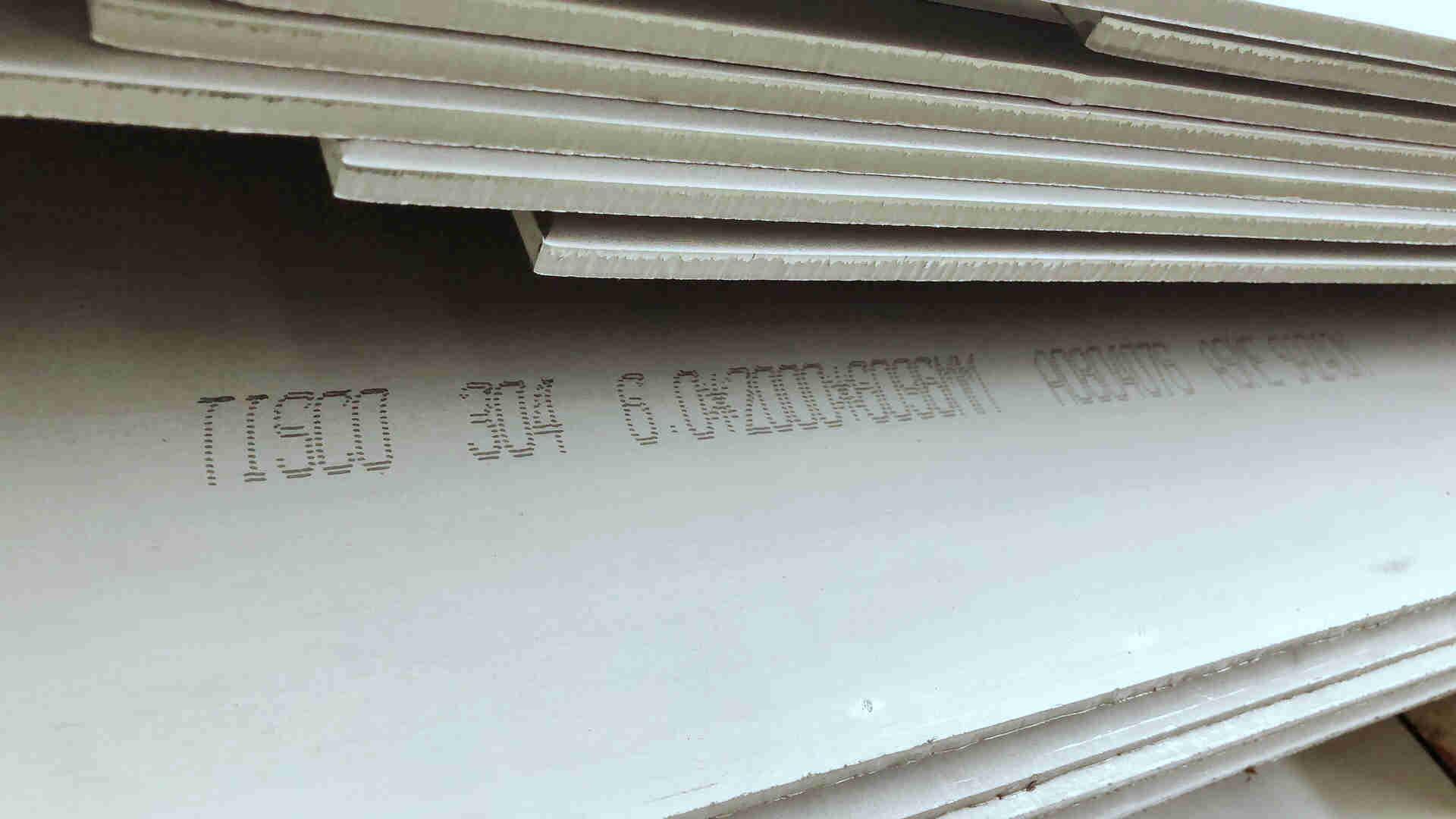

Gangsteel produce and export ASTM A240 304H stainless steel plate, ASTM A240 TP304H Stainless Steel No.1 Finish Plate and we supply TP304H stainless steel stock list thickness 2mm to 300mm at Origin China. We are the large stainless material factory supplier in China.

density of 304h|nssw yt-304h|304h plate suppliers|304h properties|304h oj-201|304l or 304h|304 or 304h|304h 1.4948|suppliers of 304h stainless steel|sensitization of 304h stainless steel|ss 304h material|304h 304|ldm-304h-xy|l-304 hd|304h 304l|lincoln lnt 304h|sa-479-304h|ldm-304h|linija 304h|304 hp l|304h material properties|super 304h material|y2-304h|304h p number|304h metallurgy|sa-240 304h properties|304h material composition|304h mechanical properties|304h means|n-304h|304h pwht|thermanit 304h|temperature 304h|t-304h|type 304h|tbi 304h|304h tensile strength|304h tig wire|tp 304h stainless steel|304h uns|304h plate uk|304h vs 347h|304h vs 316h|304h vs 316|304h stainless steel use|304h vs 304 ss|304h vs 310|304h stainless steel uk|304h vs 321h|s304h|s-304h-cctk|304h temperature range|304h stainless round bar

Stainless metal 304 and stainless steel 304L are also called 1.4301 and 1.4307 respectively. It is still typically referred to by its old name 18/8 which is derived from the nominal composition of type 304 being 18% chromium and eight% nickel. Type 304 stainless-steel is an austenitic grade that may be severely deep drawn.

Post-weld annealing is not required when welding skinny sections.Grade 304L, the low carbon version of 304, doesn’t require submit-weld annealing and so is extensively utilized in heavy gauge elements . Nitronic 60 uniform corrosion resistance is healthier than 304 stainless in most environments. The yield energy of Nitronic 60 is almost twice that of 304 and 316 stainless steels.

Which metal has the highest melting point?

Of all metals in pure form, tungsten has the highest melting point (3,422 °C, 6,192 °F), lowest vapor pressure (at temperatures above 1,650 °C, 3,000 °F), and the highest tensile strength.

Compared with 304 alloy, 321 stainless steel has better ductility and resistance to emphasize fracture. In addition, 304L can be used for anti-sensitization and intergranular corrosion. Stainless steel’s resistance to corrosion and marking, low maintenance, relatively low price, and familiar lustre make it a perfect material for many functions.

They are a part of the 300 Series of steels which covers a variety of austenitic chromium-nickel alloys. They are also known as 18/eight stainless due to their chemical composition which incorporates roughly 18% chromium and eight% nickel by weight. The steels are easy to kind, weld, and fabricate and their resistance to corrosion from, amongst different things, acids naturally contained in food has resulted in them being used broadly within the food and drinks processing industries.

304h material equivalent|304h thermal expansion|304h stainless steel equivalent|304h din|aisi 304h datasheet|304h 304l difference|john deere 304h parts|304h stainless steel density|304h round bar houston|304h bmtc bus route|304h allowable stress|304h alloy|aisi 304h stainless steel|a479 304h|304h angle|304h astm|304 honey|304 help|304h tubing|a358 304h|astm 304h stainless steel|304h bearing|304h barden|304h bolts|b-304h|304h bar|304h bar stock|a 312 tp 304h|a 240 304h|304h bus route|aisi 304h equivalent|304h pipe europe|hb-304h|veh-304hpd-h|what is 304h stainless steel|

ASTM A240 TP304H Plates

Carbide particles tend to precipitate at grain boundaries when austenitic stainless steels are held in or slowly cooled by way of the temperature vary °F ( °C). The higher levels of chromium and nickel contained in these alloys ends in decrease carbon solubility, which tends to extend the susceptibility for sensitization. Forced quenchant cooling is recommended A240 SS304H Stainless factory through the crucial temperature range, notably for thicker sections. The time at temperature required to kind chromium carbides will increase with reducing carbon content.

ASTM A240 TP304H Stainless Steel Bright Annealed Finish Plate

304H stainless steel belt, SUS304H stainless steel belt, 304H stainless steel belt, 0Cr18Ni9, 304-general model; namely 18/8 stainless steel. The GB grade is 0Cr18Ni9.

Vickers hardness (HV) 370°-420° and Hardness tolerance (HV) ±20°

Relative Keywords:

304h|304 house|304h stainless steel|304h vs 304l|304h stainless|304h chemical composition|304h pipe|304h ss|304h material|inox 304h|sa 240 304h|veh-304hcd-k|304h round bar|304h stainless steel properties|has-304h|304h plate|super 304h chemical composition|cdv2-304hn n|f304h|a240 304h|f-c304h|304h sheet|304h edelstahl|c304h|super 304h composition|lfd-304h|s-304h-cct|est-304h|veh-304hcc-k|304h vs 304|304h pipe suppliers|hlh-304h|304h steel|304h stainless steel round bar|304h stainless steel sheet|304h fittings|304h vs 304l stainless steel|s-304h-ab|304h composition|304h stainless steel composition|304h stainless steel temperature limits|yt-304h|welding 304h stainless steel|304h werkstoff|aisi 304h properties|304h outokumpu|zinsser 304h|cdv2-304hn n pdf|density of 304h stainless steel|

a240 Type 304H widely used material.

Corrosion resistance, heat resistance, good mechanical properties, good processing performance at room temperature such as deep drawing, bending, etc., will not harden after heat treatment, can withstand general rust in the building, and can resist erosion by food processing media (but contains concentrated acid

Corrosion may occur due to high temperature and chloride components), and it can resist organic compounds, dyes and a wide variety of inorganic compounds.

ASTM A240 Stainless Steel 304H Chemical Composition

| Type |

Grade |

ASTM A240 Chemical Composition |

|||||||||

|

ASTM(A240M) |

Others(JIS) |

C |

Si |

Mn |

P |

S |

Ni |

Cr |

Mo |

Others |

|

|

Austenitic Steels |

|||||||||||

|

304H |

0.04/0.10 |

≤0.75 |

≤2.00 |

≤0.045 |

≤0.030 |

8.0/10.5 |

18.0/20.0 |

― |

|||

A240 Type 304L (low carbon), good resistance to nitric acid, and durable for medium temperature and concentration of sulfuric acid, widely used as liquid gas storage tanks, low temperature equipment (304N), appliances and other consumer products, kitchen equipment, hospital equipment, transportation Tools, wastewater treatment equipment.

Alloy 304 (S30400), 304L (S30403), and 304H (S30409) stainless steels are 18% chromium, 8% nickel austenitic alloys, which are the most common and commonly used alloys in the stainless steel family. Because these alloys have one or more of the following properties, they can be used in various applications.

Properties include:

STM A240 TP304H Stainless Steel Plate Physical Properties

| Grade |

Density (kg/m3) |

Elastic Modulus (GPa) |

Mean Coefficient of Thermal Expansion (m/m/0C) |

Thermal Conductivity (W/m.K) |

Specific Heat 0-1000C (J/kg.K) |

Electrical Resistivity (n.m) |

|||

|

0-1000C |

0-3150C |

0-5380C |

at 1000C |

at 5000C |

|||||

|

304H |

8000 |

193 |

17.2 |

17.8 |

18.4 |

16.2 |

21.5 |

500 |

720 |

A high-alloy steel A240 304h that can resist corrosion in the air or in chemically corrosive media. It has a beautiful surface and good corrosion resistance. It does not need to undergo surface treatment such as plating, but exerts its inherent surface properties. It is used in various steels.

One kind, usually called stainless steel.

High alloy steels such as 13 chromium steel and 18-chromium nickel steel are representative of performance.

Others relative stainless keywords:

what is 304h material| 304h |304h plate in houston|304h hardness|304h high temperature|304h hardness brinell|304h pipe houston|what is 304h stainless|aço inox 304h|jis 304h|304h loader|304h larson miller|lnt 304h|304h john deere loader|304h john deere|tube inox 304h|acero inoxidable 304h|soudage inox 304h|gatunek 304h|sa240 gr 304h|304h pipe and fittings|stainless steel 304h flanges|304h stainless steel fittings|f304h vs f304|304h ferrite number|304h filler metal|304 h en minute|304h flat bar|304h flanges|f304h chemical composition|f304h equivalent|304h grain size|304h grade|gd-304h|a240 gr 304h|sus f304h|werkstoff f304h|sa 182 f 304h|a182 f304h chemical composition|a182 f304h temperature|lnm 304h|

From a metallographic point of view, because stainless steel contains chromium, a very thin chromium film is formed on the surface. This film isolates the intruding oxygen from the steel for corrosion resistance.

In order to maintain the inherent corrosion resistance of stainless steel, steel must contain more than 12% chromium

SS 304H Plate Equivalent grades

| STANDARD |

WERKSTOFF NR. |

UNS |

JIS |

AFNOR |

BS |

GOST |

EN |

|

SS 304H |

1.4948 |

S30409 |

– |

– |

– |

– |

– |

304, 304L, and 304H alloys are the most prone to stress corrosion cracking (SSC) among austenitic stainless steels because of their relatively low nickel content.

The conditions that cause stress corrosion cracking are: (1) the presence of halide ions (usually chloride), (2) residual tension, and (3) the temperature exceeds 120°F (49°C).

Cold deformation during alloy forming, stenting into tube sheet, welding operations, etc. can all cause stress.

Annealing and stress relief heat treatment after cold deformation can reduce stress, thus reducing the possibility of halide stress corrosion cracking.

In the environment that may cause intergranular corrosion, it is best to choose low-carbon 304L alloy when working under low-temperature annealing.

AASTM A240 Stainless Steel 304H Plate Mechanical Properties

| Type |

Mechanical Properties for Stainless Steel Plates, Stainless Steel Sheet |

|||||||

|

ASTM(A240M) |

Others(JIS) |

Tensile Properties |

Hardness |

|||||

|

Yield Strength (Mpa) |

Tensile Strength (Mpa) |

Elongation (%) |

HBW |

HRBW |

||||

|

AusteniticSteels |

||||||||

|

304H |

≥205 |

≥515 |

≥40 |

≤201 |

≤92 |

|||

SS 409 Sheets are used in varied applications similar to automotive and truck exhaust methods, tubular manifolds, agricultural spreaders, gasoline turbine exhaust silencers, warmth exchangers and gasoline filters. The general corrosion resistance of Type 409 is just like Type 410, performing far superior to carbon steel merchandise in most purposes. Alloy 317L is a molybdenum-bearing austenitic chrome steel with significantly increased resistance to chemical assault as compared to the traditional chromium-nickel austenitic stainless steels similar to Alloy 304. In addition, Alloy 317L presents higher creep, stress-to-rupture, and tensile strength at elevated temperatures than typical stainless steels.

Extended elevated temperature exposure can reduce each the toughness and corrosion resistance of alloy 2507.Duplex 2507 possesses excellent mechanical properties. Often a lightweight gauge of 2507 material can be used to achieve the identical design power of a thicker nickel alloy.

ASTM A240 TP304H Stainless Steel Cut to Size Plate

- Therefore, the low carbon variations of these alloys are extra resistant but not resistant to sensitization.

- When heated at temperatures between °F ( °C) for lengthy periods of time, Alloys 309/309S and 310/310S can exhibit decreased ductility at room temperature due to the precipitation of brittle second phase particles .

- Sigma part often types at grain boundaries and can scale back ductility.

- Pragati Metals is a noteworthy producer, supplier and exporter of Stainless Steel 409 Sheets and Plates in Mumbai, India.

Stainless steel grating is used for commercial and industrial flooring that enables the sunshine, air, heat, and sound to cross between ground ranges. Low carbon steels are categorized by having lower than 0.3% carbon by weight. This permits A36 metal to be easily machined, welded, and fashioned, making it extremely helpful as a common-purpose metal. The low carbon additionally prevents heat treatment from having a lot of an impact on A36 steel. A36 steel often has small quantities sus309s Heat resistant temperature China Buy A36 Steel High Temperature Carbon Steel Plate – Buy High Temperature Feature of hot rolled steel plate sheet.

What is 304h stainless steel?

Alloy 304/304H (UNS S30400/ S30409) is a modification of the most widely utilized “18-8” chromium-nickel austenitic stainless steel. It is an economical and versatile corrosion resistant alloy suitable for a wide range of general purpose applications. It is common practice for 304H to be dual certified as 304 and 304H.

Although types 201 and 202 have somewhat less resistance to chemical corrosion than 301 and 302, their resistance to atmospheric corrosion is totally comparable. To keep away from carbide precipitation during welding, low-carbon sorts 304L and 316L were developed which incorporates solely 0.03 p.c carbon .

304h steel

Carbide precipitation occurs at temperatures starting from about 450 to 850°C. C95400 Alumimum Bronze is the frequent and popular of the aluminum bronze alloys.

|what is 304h|rx-304h|304h yield strength|304h vs 316l|p-304h-ab|304h round bar uk|john deere 304h wheel loaders|sharp rp-304h|304h stainless steel data sheet|304h stainless steel chemical composition|john deere 304h loader specs|304h welding wire|304h welding|304h rohre|super 304h welding|304h pipe stock|tole inox 304h|husky c304h air compressor|304h data sheet|304h density|deere 304h specs|p-304h-cct|crane 304h cam|304h carbon content|304h chemistry|304h coefficient of thermal expansion|304h creep strength|deere 304h|deere 304h for sale|304h equivalent|

Gangsteel mainly products are 304h Square tube,304h stainless,304h Rectangular tube,304h seamless pipes,304h seamless tubes,304h welded pipes,304h angle bar,304h H Beam,304h channel beam,304h round bar ,304h cutting part,304h machine part,304H CNC cutting parts,304H water jet cutting parts,304H laser cutting parts and stainless steel 304h. If you have requirement, please contact us by email admin@gangsteel.com