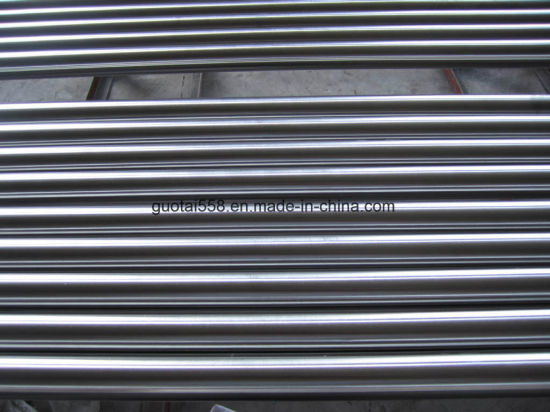

316 And 316l Stainless Steel

We produce ASTM/ASME Grade 304, Grade 304L,304h, 316, 316L, 316H, 316TI, 321, 321H, 309S, 309H, 310S, 310H, 410S, 2205, 904L, 2507, 254, gh3030, 625, 253MA, S30815, 317L, Type 317, 316lN, 8020, 800, 800H, C276, S32304 and others special requirement stainless steel grade.

The ensuing iron oxide floor layer is porous and fragile. In addition, as iron oxide occupies a bigger volume than the original metal, this layer expands and tends to flake and fall away, exposing the underlying metal to additional attack. This passive movie prevents further corrosion by blocking oxygen diffusion to the metal surface and thus prevents corrosion from spreading into the majority of the metal.

The properties of duplex stainless steels are achieved with an general lower alloy content material than similar-performing tremendous-austenitic grades, making their use value-effective for many applications. The pulp and paper business was one of many first to extensively use duplex stainless steel. Today, the oil and gasoline industry is the most important person and has pushed for extra corrosion resistant grades, resulting in the development of tremendous duplex and hyper duplex grades. Ferritic stainless steels possess a ferrite microstructure like carbon steel, which is a physique-centered cubic crystal structure, and include between 10.5% and 27% chromium with very little or no nickel.

Austenitic stainless steels such as 304 or 316 have excessive quantities of nickel and chromium. The chromium combines with the oxygen earlier than the iron is ready to which types a chromium oxide layer. This layer may be very corrosion resistant which prevents rust formation and protects the underlying steel.

Welding Stainless Steels

Brand��Chanson,TISCO,BAOSTEEL,POSCO,JISCO,LISCO

- Stainless steels have a long historical past of application in touch with water because of their wonderful corrosion resistance.

- The minimal 10.5% chromium in stainless steels provides resistance to roughly seven hundred °C (1,300 °F), while sixteen% chromium offers resistance as much as approximately 1,200 °C (2,200 °F).

- Resistance to different gases depends on the type of fuel, the temperature, and the alloying content material of the stainless-steel.

- Type 304, the commonest grade of stainless-steel with 18% chromium, is immune to roughly 870 °C (1,600 °F).

- Other gases, such as sulfur dioxide, hydrogen sulfide, carbon monoxide, chlorine, also attack stainless steel.

Our stainless production range

In fact, all stainless steels by definition comprise a minimum of 10 percent chromium. While these metals don’t rust, that does not imply that they don’t corrode. They have their own forms of corrosion, corresponding to pitting that can happen in stainless steel or the blue-inexperienced tarnish found on oxidized copper. Furthermore, if they are introduced into contact with a carbon steel or other type of steel that does rust, iron deposits can be made on the floor of these supplies that will oxidize and create rust. The ease of welding largely is dependent upon the type of chrome steel used.

The identical grades exposed to stronger bases corresponding to sodium hydroxide at high concentrations and excessive temperatures will probably expertise some etching and cracking. Increasing chromium and nickel contents provide elevated resistance.

The invention of stainless steel followed a series of scientific developments, starting in 1798 when chromium was first proven to the French Academy by Louis Vauquelin. In the early 1800s, James Stodart, Michael Faraday, and Robert Mallet noticed the resistance of chromium-iron alloys (“chromium steels”) to oxidizing brokers. Robert Bunsen discovered chromium’s resistance to sturdy acids.

The minimum 10.5% chromium in stainless steels supplies resistance to roughly 700 °C (1,300 °F), while sixteen% chromium supplies resistance as much as approximately 1,200 °C (2,200 °F). Type 304, the most typical grade of stainless-steel with 18% chromium, is resistant to approximately 870 °C (1,600 °F).

We have thousands tons stock of stainless steel sheet and coil with various size and grade,mainly include austenitic stainless steel, martens stainless steel (including precipitation hardened stainless steel sheet & coil), ferritic stainless steel, and duplex stainless steel.

Characteristics of Stainless Steel Sheet and Plate:

High corrosion resistance

High strength

High toughness and impact resistance

Temperature resistance

High workability, including machining, stamping, fabricating and welding

Smooth surface finish that can be easily clean