What’s The Difference Between 304 And 316 Stainless Steel?

We produce ASTM/ASME Grade 304, Grade 304L,304h, 316, 316L, 316H, 316TI, 321, 321H, 309S, 309H, 310S, 310H, 410S, 2205, 904L, 2507, 254, gh3030, 625, 253MA, S30815, 317L, Type 317, 316lN, 8020, 800, 800H, C276, S32304 and others special requirement stainless steel grade.

It has a microstructurethat contains an addition of Nitrogen, Nickel, and Manganese. The construction of austenitic stainless-steel is identical as what you’d find in common metal. But solely in a much higher temperature giving it formability and weldability. Furthermore, you can make austenitic stainless steel corrosion resistant by adding Nitrogen, Chromium, and Molybdenum. While you can not harden it with heat, austenitic stainless-steel has the useful property of retaining a useful level of toughness and ductility when hardened to high power.

Unlike carbon metal, stainless steels do not suffer uniform corrosion when exposed to moist environments. Unprotected carbon metal rusts readily when exposed to a mixture of air and moisture.

Typical austenitic stainless steelis prone to emphasize corrosion cracking, however austenitic stainless steel with greater nickel content has elevated resistance to stress corrosion cracking. Nominally non-magnetic, austenitic stainless steel shows some magnetic response depending on its composition. Type 304, with its chromium-nickel content material and low carbon, is the most versatile and broadly used of the austenitic stainless steels.

Application:kitchware,door,decoration,elevator,water tank,etc

- Since Type 316 stainless steel alloy incorporates molybdenum bearing it has a larger resistance to chemical assault than 304.

- Type 316 is sturdy, easy-to-fabricate, clear, weld and end.

- It is significantly more immune to options of sulfuric acid, chlorides, bromides, iodides and fatty acids at high temperature.

- The bottom line is that Type 316 stainless steel prices slightly extra upfront however you can save an entire lot on the back end – especially in case your enclosure goes for use outdoors.

The Leader In Small-amount Metals

Our stainless production range

Resistance to other gases relies on the kind of gasoline, the temperature, and the alloying content of the chrome steel. Austenitic chrome steel is one of the most common types of chrome steel on this record.

Duplex stainless-steel can be magnetic with moderate formability. Due to the addition of molybdenum, grade 316 stainless-steel is more corrosion resistant than similar alloys, such as 304 chrome steel. This reduces pitting from chemical environments and permits grade 316 stainless-steel for use in highly acidic and caustic environments that would otherwise eat away on the steel.

Companies use martensitic stainless-steel imostly in long products that require sheet and plate kind. The increased nickel content material and the inclusion of molybdenum makes grade 316 chrome steel a bit costlier than grade 304 per ounce of material.

Joining Stainless Steels

The chromium combines with the oxygen earlier than the iron is able to which types a chromium oxide layer. This layer may be very corrosion resistant which prevents rust formation and protects the underlying steel. On the other hand, ferritic or martensitic stainless steels may be vulnerable to rust because they comprise much less chromium. What makes the grade 316 alloy an ideal food grade steel sheet materials is the truth that it has a high resistance to acids, alkalis, and chlorides (similar to salt).

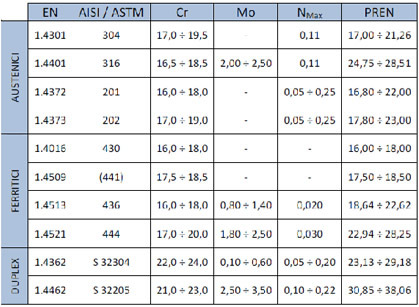

We have thousands tons stock of stainless steel sheet and coil with various size and grade,mainly include austenitic stainless steel, martens stainless steel (including precipitation hardened stainless steel sheet & coil), ferritic stainless steel, and duplex stainless steel.

Characteristics of Stainless Steel Sheet and Plate:

High corrosion resistance

High strength

High toughness and impact resistance

Temperature resistance

High workability, including machining, stamping, fabricating and welding

Smooth surface finish that can be easily clean