Stainless Steel

We produce ASTM/ASME Grade 304, Grade 304L,304h, 316, 316L, 316H, 316TI, 321, 321H, 309S, 309H, 310S, 310H, 410S, 2205, 904L, 2507, 254, gh3030, 625, 253MA, S30815, 317L, Type 317, 316lN, 8020, 800, 800H, C276, S32304 and others special requirement stainless steel grade.

Applications include a spread of situations together with plumbing, potable water and wastewater treatment, desalination, and brine therapy. Types 304 and 316 stainless steels are normal supplies of construction in contact with water. However, with increasing chloride contents, larger alloyed stainless steels corresponding to Type 2205 and super austenitic and tremendous duplex stainless steels are used. Among wrought stainless steels, the composition of AISI 304 chrome steel is notable for holding comparatively excessive quantities of chromium (Cr) and nickel (Ni).

Chromium is the defining alloying factor of stainless steel. Higher chromium content imparts additional corrosion resistance. Nickel is primarily used to attain a specific microstructure. In addition, it has a useful effect on mechanical properties and sure forms of corrosion.

Other gases, corresponding to sulfur dioxide, hydrogen sulfide, carbon monoxide, chlorine, also attack stainless steel. Resistance to other gases relies on the type of fuel, the temperature, and the alloying content material of the stainless-steel. Stainless steels have a long history of software in contact with water because of their glorious corrosion resistance.

Delivery time��7 to 15 days, depends on the quantity

- The minimal 10.5% chromium in stainless steels supplies resistance to approximately 700 °C (1,300 °F), whereas 16% chromium supplies resistance up to roughly 1,200 °C (2,200 °F).

- Type 304, the most typical grade of stainless steel with 18% chromium, is proof against approximately 870 °C (1,600 °F).

- Other gases, similar to sulfur dioxide, hydrogen sulfide, carbon monoxide, chlorine, also assault stainless steel.

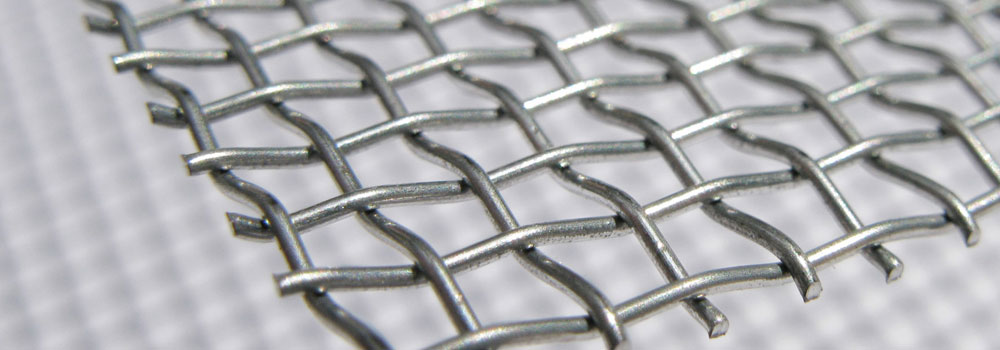

Our stainless production range

There are a couple of factors that can have an effect on the corrosion resistance of stainless steel. The composition of the metal affects corrosion resistance. Even within grades of stainless-steel, impurities in the steel can have an effect on the corrosion resistance.

In all environments, properly passivating your stainless steel will stop it from rusting. Some 3D printing providers have developed proprietary chrome steel sintering blends to be used in fast prototyping.

Water

This microstructure is current at all temperatures due to the chromium addition, so they are not hardenable by heat treatment. They can’t be strengthened by chilly work to the same degree as austenitic stainless steels. The ease of welding largely is determined by the type of chrome steel used. Austenitic stainless steels are the easiest to weld by electrical arc, with weld properties much like these of the base steel (not cold-worked). Post-weld warmth therapy is nearly all the time required while preheating before welding is also necessary in some circumstances.

The surroundings is one other huge factor in stainless steel rust. Environments with chlorine, like swimming swimming pools, are extremely corrosive. Salt water environments affect stainless-steel, just to a lesser extent than carbon steel.

We have thousands tons stock of stainless steel sheet and coil with various size and grade,mainly include austenitic stainless steel, martens stainless steel (including precipitation hardened stainless steel sheet & coil), ferritic stainless steel, and duplex stainless steel.

Characteristics of Stainless Steel Sheet and Plate:

High corrosion resistance

High strength

High toughness and impact resistance

Temperature resistance

High workability, including machining, stamping, fabricating and welding

Smooth surface finish that can be easily clean