Stainless Steel 304

We produce ASTM/ASME Grade 304, Grade 304L,304h, 316, 316L, 316H, 316TI, 321, 321H, 309S, 309H, 310S, 310H, 410S, 2205, 904L, 2507, 254, gh3030, 625, 253MA, S30815, 317L, Type 317, 316lN, 8020, 800, 800H, C276, S32304 and others special requirement stainless steel grade.

The chromium protects the product from oxidization or rust, whereas the nickel content material rescues the meals grade drum from corrosion. The larger the nickel content material, the extra resistant the stainless-steel is to corrosion. Note that chrome steel produced in countries that use cleaner sources of electrical energy (such as France, which makes use of nuclear vitality) will have a lower carbon footprint. Ferritics without Ni will have a decrease CO2 footprint than austenitics with eight% Ni or extra. Austenitic (300 sequence) stainless-steel, notably Types 304 and 316, is the material of choice for the meals and beverage business, though martensitic and ferritic (400 sequence) steels are also used.

At elevated temperatures, all metals react with hot gases. The commonest excessive-temperature gaseous combination is air, of which oxygen is essentially the most reactive part. To keep away from corrosion in air, carbon metal is restricted to roughly 480 °C (900 °F). Oxidation resistance in stainless steels will increase with additions of chromium, silicon, and aluminium. Small additions of cerium and yttrium increase the adhesion of the oxide layer on the floor.

In addition, as iron oxide occupies a bigger volume than the original metal, this layer expands and tends to flake and fall away, exposing the underlying steel to additional assault. This passive movie prevents further corrosion by blocking oxygen diffusion to the metal surface and thus prevents corrosion from spreading into the majority of the steel. This film is self-repairing, even when scratched or temporarily disturbed by an upset condition within the environment that exceeds the inherent corrosion resistance of that grade. When selecting a stainless-steel that must endure corrosive environments, austenitic stainless steels are sometimes used.

Standard��ASTM,AISI,SUS,JIS,EN,DIN,GB,ASME,ETC

Stock Thickness: 0.1-200.0mm

Production thickness: 0.5.0-200mm

Width: 600-3900mm

Length: 1000-12000mm

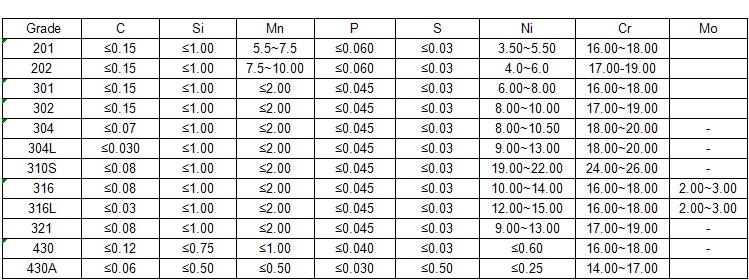

Grade:

200 series: 201,202

300 series: 301,304,304L,304H,309,309S,310S,316L,316Ti,321,321H,330

400 series: 409,409l,410,420J1,420J2,430,436,439,440A/B/C

Duplex: 329,2205,2507,904L,2304

Surface: No.1,1D,2D,2B,NO.4/4K/hairline,satin,6k,BA,mirror/8K

- The minimum 10.5% chromium in stainless steels offers resistance to roughly 700 °C (1,300 °F), whereas sixteen% chromium offers resistance as much as approximately 1,200 °C (2,200 °F).

- Resistance to different gases relies on the type of fuel, the temperature, and the alloying content of the chrome steel.

- Other gases, corresponding to sulfur dioxide, hydrogen sulfide, carbon monoxide, chlorine, additionally attack stainless-steel.

- Type 304, the commonest grade of chrome steel with 18% chromium, is proof against approximately 870 °C (1,600 °F).

The properties of duplex stainless steels are achieved with an general decrease alloy content than similar-performing tremendous-austenitic grades, making their use cost-effective for a lot of functions. The pulp and paper trade was one of the first to extensively use duplex chrome steel. Today, the oil and fuel business is the biggest user and has pushed for more corrosion resistant grades, leading to the event of tremendous duplex and hyper duplex grades.

Robert Bunsen discovered chromium’s resistance to sturdy acids. The corrosion resistance of iron-chromium alloys could have been first acknowledged in 1821 by Pierre Berthier, who famous their resistance against attack by some acids and advised their use in cutlery. Similar to 304, Grade 316 stainless steel has high quantities of chromium and nickel. 316 additionally contains silicon, manganese, and carbon, with the vast majority of the composition being iron. The larger molybdenum content leads to grade 316 possessing increased corrosion resistance.

Stainless Steel 304

This microstructure is current in any respect temperatures due to the chromium addition, so they don’t seem to be hardenable by heat therapy. They can’t be strengthened by chilly work to the identical diploma as austenitic stainless steels. Grade 304 chrome steel is usually regarded as the most typical austenitic stainless steel.

The ease of welding largely depends on the type of stainless-steel used. Austenitic stainless steels are the best to weld by electrical arc, with weld properties similar to those of the base steel (not cold-labored). Post-weld warmth therapy is almost all the time required while preheating earlier than welding can be needed in some cases. Galling, generally called cold welding, is a form of extreme adhesive wear, which might occur when two metallic surfaces are in relative movement to each other and beneath heavy pressure.

We have thousands tons stock of stainless steel sheet and coil with various size and grade,mainly include austenitic stainless steel, martens stainless steel (including precipitation hardened stainless steel sheet & coil), ferritic stainless steel, and duplex stainless steel.

Characteristics of Stainless Steel Sheet and Plate:

High corrosion resistance

High strength

High toughness and impact resistance

Temperature resistance

High workability, including machining, stamping, fabricating and welding

Smooth surface finish that can be easily clean