So ..Is Stainless Steel Really Stainless?

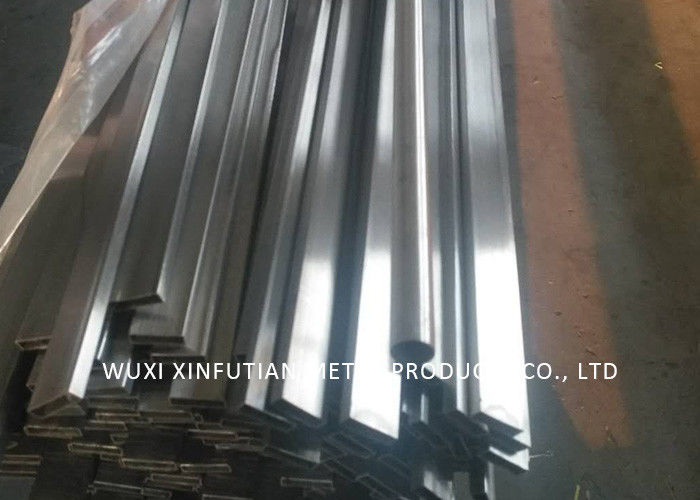

We produce ASTM/ASME Grade 304, Grade 304L,304h, 316, 316L, 316H, 316TI, 321, 321H, 309S, 309H, 310S, 310H, 410S, 2205, 904L, 2507, 254, gh3030, 625, 253MA, S30815, 317L, Type 317, 316lN, 8020, 800, 800H, C276, S32304 and others special requirement stainless steel grade.

In addition,AISI 304 has a 18% Cr and 8% Ni and therefore generally known as 18-eight stainless-steel, whereas AISI 316 has a 16% Chromium and 10% Nickel. Another main distinction between 430 and 316 stainless-steel is that grade 430 SS is a ferritic alloy, which means that it’s magnetic by default. Ferritic alloys like 430 SS even have extraordinary resistance to emphasize corrosion cracking (the growth of crack formations that may cause sudden failure in corrosive environments). As an alloy, chrome steel 430 meals grade metallic is similar to grade 316 stainless.

The corrosion resistance of iron-chromium alloys may have been first acknowledged in 1821 by Pierre Berthier, who noted their resistance in opposition to assault by some acids and suggested their use in cutlery. austenitic chrome steel, commonly called “marine grade” stainless steel. It is utilized in environments which might be highly corrosive. It is composed of 16-18% chrome, 10%-14% nickel, & 2%-three% molybdenum (has higher resistance to corrosion at higher temperatures than nickel). T316 is for saltwater purposes and is an option for steam kettles which might be used with excessive acid merchandise like chili manufacturing.

The identical grades exposed to stronger bases such as sodium hydroxide at excessive concentrations and excessive temperatures will likely expertise some etching and cracking. Increasing chromium and nickel contents provide increased resistance. The properties of duplex stainless steels are achieved with an general lower alloy content than similar-performing super-austenitic grades, making their use cost-effective for many functions. The pulp and paper trade was one of the first to extensively use duplex stainless steel. Today, the oil and gas trade is the biggest user and has pushed for more corrosion resistant grades, resulting in the event of tremendous duplex and hyper duplex grades.

Cold Rolled,Hot Rolled Stainless steel Plate and sheets

Our stainless production range

- Resistance to different gases depends on the kind of fuel, the temperature, and the alloying content of the chrome steel.

- The minimum 10.5% chromium in stainless steels provides resistance to approximately seven-hundred °C (1,300 °F), while 16% chromium supplies resistance as much as roughly 1,200 °C (2,200 °F).

- Other gases, such as sulfur dioxide, hydrogen sulfide, carbon monoxide, chlorine, additionally attack stainless steel.

- Type 304, the commonest grade of stainless steel with 18% chromium, is resistant to roughly 870 °C (1,600 °F).

This grade is also very ductile, and has good weldability enabling its widespread usage in lots of applications. What makes the grade 316 alloy a perfect meals grade metal sheet materials is the fact that it has a excessive resistance to acids, alkalis, and chlorides (similar to salt). Other austenitic stainless steels, similar to grade 304 SS, can experience severe pitting corrosion when exposed to salt, which is often present in food products.

They cannot be strengthened by chilly work to the same degree as austenitic stainless steels. Austenitic stainless steel is the largest family of stainless steels, making up about two-thirds of all stainless steel production (see production figures under).

Stainless Steel Designations Table

When the 2 surfaces are of the same materials, these uncovered surfaces can easily fuse. Separation of the two surfaces may end up in floor tearing and even full seizure of steel components or fasteners. Ferritic stainless steels possess a ferrite microstructure like carbon metal, which is a body-centered cubic crystal construction, and include between 10.5% and 27% chromium with very little or no nickel. This microstructure is present in any respect temperatures as a result of chromium addition, so they are not hardenable by warmth remedy.

Type 304

Note that chrome steel produced in international locations that use cleaner sources of electricity (such as France, which uses nuclear energy) may have a decrease carbon footprint. Ferritics with out Ni could have a decrease CO2 footprint than austenitics with eight% Ni or extra. The ease of welding largely depends on the type of stainless-steel used. Austenitic stainless steels are the easiest to weld by electric arc, with weld properties much like those of the bottom metal (not cold-labored). Post-weld heat remedy is sort of at all times required while preheating earlier than welding can be necessary in some instances.

We have thousands tons stock of stainless steel sheet and coil with various size and grade,mainly include austenitic stainless steel, martens stainless steel (including precipitation hardened stainless steel sheet & coil), ferritic stainless steel, and duplex stainless steel.

Characteristics of Stainless Steel Sheet and Plate:

High corrosion resistance

High strength

High toughness and impact resistance

Temperature resistance

High workability, including machining, stamping, fabricating and welding

Smooth surface finish that can be easily clean