316 Stainless Steel Sheet

We produce ASTM/ASME Grade 304, Grade 304L,304h, 316, 316L, 316H, 316TI, 321, 321H, 309S, 309H, 310S, 310H, 410S, 2205, 904L, 2507, 254, gh3030, 625, 253MA, S30815, 317L, Type 317, 316lN, 8020, 800, 800H, C276, S32304 and others special requirement stainless steel grade.

However, stainless steel just isn’t as commonly used as materials like Ti6Al4V, as a result of availability of less expensive conventional manufacturing methods for chrome steel. Galling, generally referred to as chilly welding, is a type of severe adhesive put on, which may occur when two metallic surfaces are in relative movement to each other and underneath heavy pressure.

The excessive chromium and nickel content material give the steel wonderful oxidation resistance as well as excessive power at excessive temperature. This grade can be very ductile, and has good weldability enabling its widespread usage in lots of applications. Stainless metal is now used as one of many materials for tramlinks, along with aluminium alloys and carbon metal.

Series—austenitic Chromium-nickel-manganese Alloys

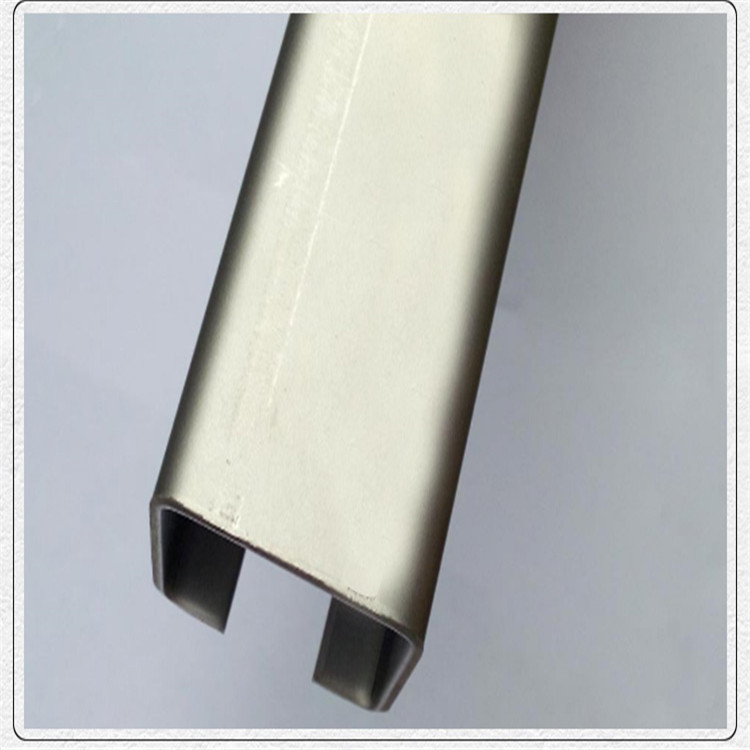

The 316 stainless steel sheet has an unpolished (mill) floor, has been annealed, meets American Society for Testing and Materials International ASTM A240 specs, and has a regular tolerance. The 316 chrome steel grade offers higher corrosion resistance than general-purpose 304 stainless-steel, particularly in marine environments, as a result of larger nickel content material and the addition of molybdenum. An austenitic chrome steel, 316 is usually nonmagnetic and may be chilly worked to extend its hardness and energy while maintaining most of its formability. The materials has been annealed, a technique of heating and cooling metallic to modify its properties, similar to growing its formability and toughness or decreasing its energy, after it has been formed. The minimum 10.5% chromium in stainless steels supplies resistance to approximately seven-hundred °C (1,300 °F), whereas sixteen% chromium provides resistance up to roughly 1,200 °C (2,200 °F).

- An austenitic stainless steel, 316 is often nonmagnetic and can be chilly worked to extend its hardness and energy whereas sustaining most of its formability.

- The 316 stainless steel grade offers higher corrosion resistance than basic-function 304 stainless-steel, particularly in marine environments, because of greater nickel content and the addition of molybdenum.

- The material has been annealed, a technique of heating and cooling metal to change its properties, such as growing its formability and toughness or reducing its strength, after it has been shaped.

- The minimal 10.5% chromium in stainless steels offers resistance to approximately seven-hundred °C (1,300 °F), while 16% chromium supplies resistance up to roughly 1,200 °C (2,200 °F).

- The 316 stainless steel sheet has an unpolished (mill) floor, has been annealed, meets American Society for Testing and Materials International ASTM A240 specs, and has a regular tolerance.

Cold Rolled,Hot Rolled Stainless steel Plate and sheets

Stock Thickness: 0.1-200.0mm

Production thickness: 0.5.0-200mm

Width: 600-3900mm

Length: 1000-12000mm

Grade:

200 series: 201,202

300 series: 301,304,304L,304H,309,309S,310S,316L,316Ti,321,321H,330

400 series: 409,409l,410,420J1,420J2,430,436,439,440A/B/C

Duplex: 329,2205,2507,904L,2304

Surface: No.1,1D,2D,2B,NO.4/4K/hairline,satin,6k,BA,mirror/8K

Small additions of cerium and yttrium increase the adhesion of the oxide layer on the surface. Type 304 and Type 316 stainless steels are unaffected weak bases corresponding to ammonium hydroxide, even in excessive concentrations and at excessive temperatures. The same grades exposed to stronger bases such as sodium hydroxide at high concentrations and high temperatures will likely experience some etching and cracking. Increasing chromium and nickel contents present elevated resistance. The properties of duplex stainless steels are achieved with an general decrease alloy content material than related-performing tremendous-austenitic grades, making their use value-effective for a lot of functions.

Austenitic stainless steel fasteners are notably susceptible to thread galling, although other alloys that self-generate a protective oxide surface film, similar to aluminium and titanium, are additionally vulnerable. Under excessive contact-drive sliding, this oxide may be deformed, broken, and removed from elements of the part, exposing the bare reactive metal.

This movie is self-repairing, even when scratched or briefly disturbed by an upset situation in the setting that exceeds the inherent corrosion resistance of that grade. Stainless metal remains stainless, or doesn’t rust, due to the interplay between its alloying elements and the surroundings.

Stainless Steel Families

Type 304, the most common grade of stainless-steel with 18% chromium, is immune to roughly 870 °C (1,600 °F). Other gases, corresponding to sulfur dioxide, hydrogen sulfide, carbon monoxide, chlorine, additionally assault chrome steel. Resistance to other gases relies on the type of gasoline, the temperature, and the alloying content of the stainless-steel.

We have thousands tons stock of stainless steel sheet and coil with various size and grade,mainly include austenitic stainless steel, martens stainless steel (including precipitation hardened stainless steel sheet & coil), ferritic stainless steel, and duplex stainless steel.

Characteristics of Stainless Steel Sheet and Plate:

High corrosion resistance

High strength

High toughness and impact resistance

Temperature resistance

High workability, including machining, stamping, fabricating and welding

Smooth surface finish that can be easily clean