zero.1 mm metal sheet provider

We produce ASTM/ASME Grade 304, Grade 304L,304h, 316, 316L, 316H, 316TI, 321, 321H, 309S, 309H, 310S, 310H, 410S, 2205, 904L, 2507, 254, gh3030, 625, 253MA, S30815, 317L, Type 317, 316lN, 8020, 800, 800H, C276, S32304 and others special requirement stainless steel grade.

How can you tell if stainless steel is good quality?

The major differences between 202 and 304 stainless steels are in the nickel and chromium contents. 202 has 16-18% chromium and 0.5-4.0% nickel, whilst 304 has 18-20% chromium and 8-10.5% nickel. The manganese helps preserve the austenitic phase in the steels, as does the nickel.

Oxidation resistance in stainless steels will increase with additions of chromium, silicon, and aluminium. Small additions of cerium and yttrium enhance the adhesion of the oxide layer on the floor. Ferritic stainless steels possess a ferrite microstructure like carbon steel, which is a body-centered cubic crystal structure, and contain between 10.5% and 27% chromium with little or no or no nickel.

The nickel content determines the grade of stainless. The chromium content material should be 18% or extra to be 304 stainless. After a 500 ton press squeezes the nickel it modifications the distribution of the nickel. The identical is true where the die cuts the stainless increasing the chance that rust will finally happen there.

Robert Bunsen found chromium’s resistance to sturdy acids. The corrosion resistance of iron-chromium alloys might have been first recognized in 1821 by Pierre Berthier, who noted their resistance towards assault by some acids and suggested their use in cutlery. The chrome steel we commonly use in our stainless casters is 304.

Compare The Two Types Of Stainless Steel

- Types 304 and 316 stainless steels are commonplace materials of construction in touch with water.

- However, with rising chloride contents, higher alloyed stainless steels such as Type 2205 and super austenitic and tremendous duplex stainless steels are used.

- Stainless steels have an extended history of application involved with water as a result of their glorious corrosion resistance.

- Applications embrace a variety of conditions including plumbing, potable water and wastewater treatment, desalination, and brine therapy.

Stock Thickness: 0.1-200.0mm

Production thickness: 0.5.0-200mm

Width: 600-3900mm

Length: 1000-12000mm

Grade:

200 series: 201,202

300 series: 301,304,304L,304H,309,309S,310S,316L,316Ti,321,321H,330

400 series: 409,409l,410,420J1,420J2,430,436,439,440A/B/C

Duplex: 329,2205,2507,904L,2304

Surface: No.1,1D,2D,2B,NO.4/4K/hairline,satin,6k,BA,mirror/8K

It is available on particular order for very giant quantity at substantial further price on a few of our stainless casters. We use the passivation process normal solely on stainless caster mannequin G15. Annealing is the best approach to restore non-magnetic property and enhance corrosion resistance. However, in this process if the stainless isn’t warmth treated high sufficient after which cooled down slowly the corrosion resistance of the chrome steel shall be reduced. Annealing stainless is sort of value prohibitive.

An enhance of chromium content material improves the corrosion resistance of stainless steel. The addition of nickel is used to lift the general corrosion resistance required in additional aggressive usage or circumstances. The presence of molybdenum (Mo) improves the localized corrosion resistance. Other alloy metals are additionally used to improve the construction and properties of stainless-steel similar to Titanium, Vanadium, and Copper. Non metallic additions typically embrace pure parts corresponding to Carbon and Nitrogen in addition to Silicon.

When both processes are applied, passivation should be done after annealing. The magnet take a look at is NOT a correct method to verify stainless-steel. Stainless steel is graded by the elements and percentages.

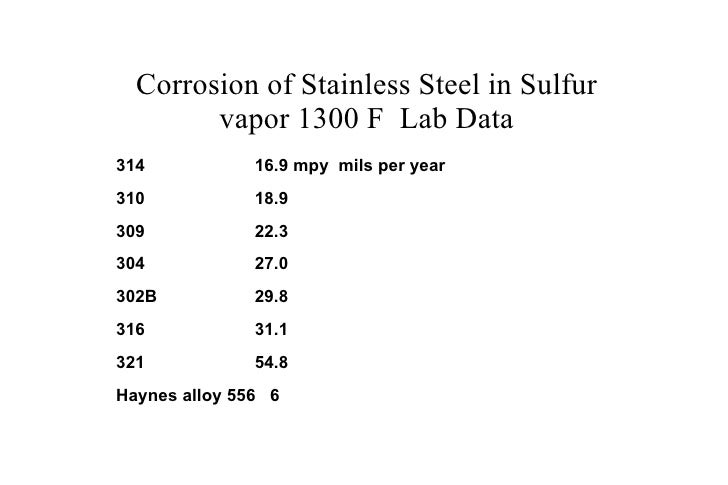

Other gases, corresponding to sulfur dioxide, hydrogen sulfide, carbon monoxide, chlorine, additionally assault stainless-steel. Resistance to other gases is dependent on the type of gas, the temperature, and the alloying content material of the stainless steel.

We have thousands tons stock of stainless steel sheet and coil with various size and grade,mainly include austenitic stainless steel, martens stainless steel (including precipitation hardened stainless steel sheet & coil), ferritic stainless steel, and duplex stainless steel.

Characteristics of Stainless Steel Sheet and Plate:

High corrosion resistance

High strength

High toughness and impact resistance

Temperature resistance

High workability, including machining, stamping, fabricating and welding

Smooth surface finish that can be easily clean