ASTM A240 304h stainless steel

Content

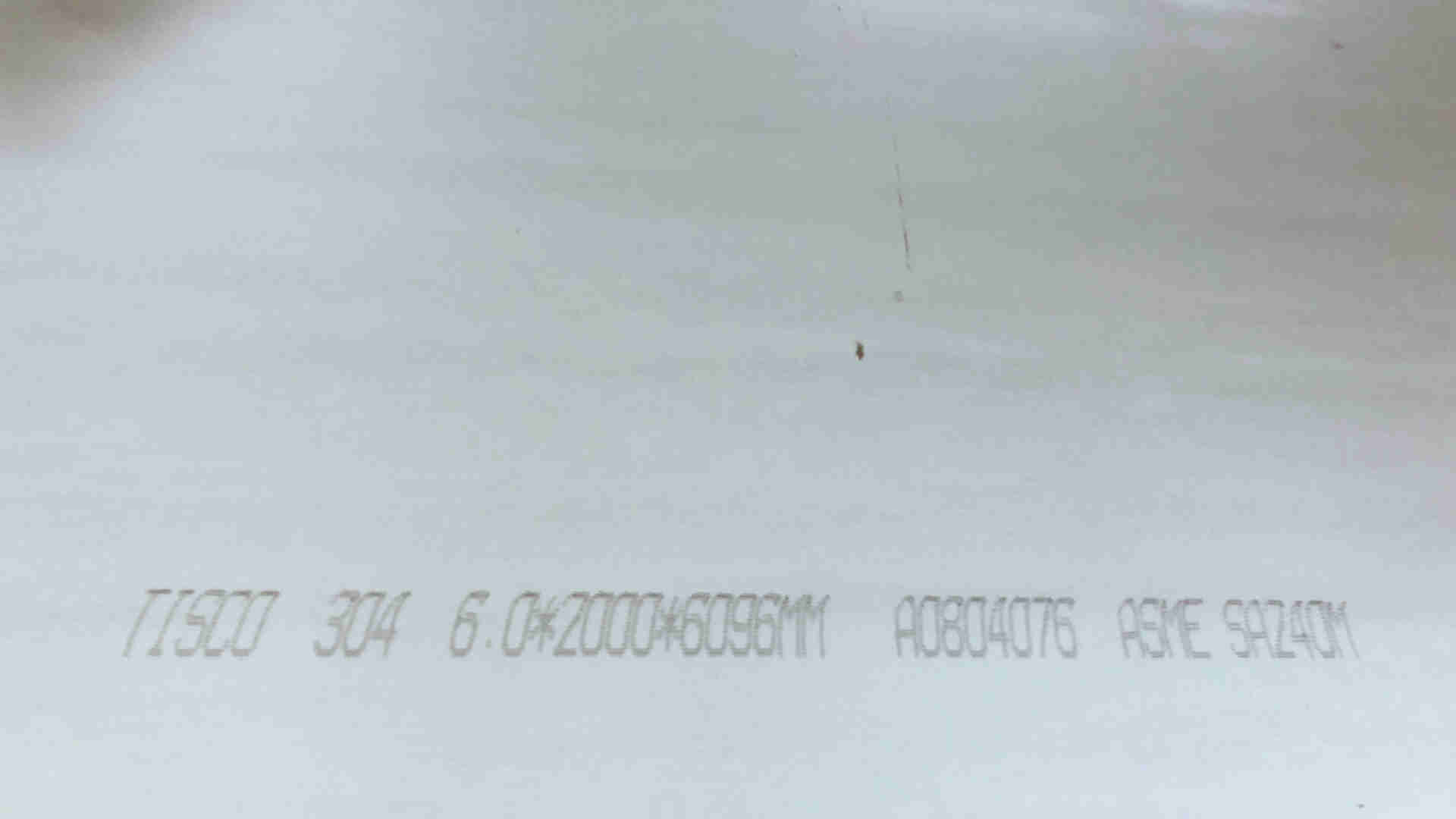

Gangsteel produce and export ASTM A240 304H stainless steel plate, ASTM A240 TP304H Stainless Steel No.1 Finish Plate and we supply TP304H stainless steel stock list thickness 2mm to 300mm at Origin China. We are the large stainless material factory supplier in China.

metal that shall be powder-coated, the corporate would want to analyze the variations within the accomplished half when utilizing a 3-kW laser slicing machine versus 4-kW gear. The larger energy stage of the 4-kW machine might give them the outcomes they need to achieve with out nitrogen. Such a microstructure confers a excessive corrosion resistance with favorable mechanical properties.

347 could be simply welded and processed by normal store fabrication methods. Good oxidation resistance and creep strength to 1500°F (816°C). 321 can be simply welded and processed by normal shop fabrication methods. Improved chloride pitting and crevice resistance to 304/304l because A240 SS304H Stainless factory of the addition of Mo. 310 can be easily welded and processed by normal shop fabrication practices. The alloy is sort of ductile and forms in a fashion similar to 316.

ASTM A240 TP304H Stainless Steel CR Plates

density of 304h|nssw yt-304h|304h plate suppliers|304h properties|304h oj-201|304l or 304h|304 or 304h|304h 1.4948|suppliers of 304h stainless steel|sensitization of 304h stainless steel|ss 304h material|304h 304|ldm-304h-xy|l-304 hd|304h 304l|lincoln lnt 304h|sa-479-304h|ldm-304h|linija 304h|304 hp l|304h material properties|super 304h material|y2-304h|304h p number|304h metallurgy|sa-240 304h properties|304h material composition|304h mechanical properties|304h means|n-304h|304h pwht|thermanit 304h|temperature 304h|t-304h|type 304h|tbi 304h|304h tensile strength|304h tig wire|tp 304h stainless steel|304h uns|304h plate uk|304h vs 347h|304h vs 316h|304h vs 316|304h stainless steel use|304h vs 304 ss|304h vs 310|304h stainless steel uk|304h vs 321h|s304h|s-304h-cctk|304h temperature range|304h stainless round bar

304h seamless tubes

304h material equivalent|304h thermal expansion|304h stainless steel equivalent|304h din|aisi 304h datasheet|304h 304l difference|john deere 304h parts|304h stainless steel density|304h round bar houston|304h bmtc bus route|304h allowable stress|304h alloy|aisi 304h stainless steel|a479 304h|304h angle|304h astm|304 honey|304 help|304h tubing|a358 304h|astm 304h stainless steel|304h bearing|304h barden|304h bolts|b-304h|304h bar|304h bar stock|a 312 tp 304h|a 240 304h|304h bus route|aisi 304h equivalent|304h pipe europe|hb-304h|veh-304hpd-h|what is 304h stainless steel|

ASTM A240 TP 420 chrome steel Rings accommodates min 0.15% and 12% Cr. TP 420 stainless steel Rings could possibly be thermally hardened to develop very excessive power. This 420 stainless steel Rings grade is ideally helpful for manufacturing cutlery.

Welding as much as 100mm thick may be carried out without the requirement of pre heating as a result of its low hardness. Applications requiring excessive fatigue power, good resistance to galling, seizing, and stress corrosion. We will certainly add more supplies, including wooden, acrylic, MDF, etc, to the platform sooner or later.

- Mastered the demagnetization process of austenitic stainless-steel more state, in accordance with customer requirements in the production of low magnetic, weak magnetic exhausting stainless-steel belt, to satisfy the needs of downstream clients.

- Customers will benefit from this high speed slicing system with decreased cycle times and faster deliveries of sunshine and intermediate thickness processed parts.

- Sandmeyer’s laser slicing system can reduce near-net shapes to the accuracy ranges and the close tolerances our buyer’s require.

- The lack of any important warmth-affected zone permits Sandmeyer to nest patterns more intently for better plate yields when compared to plasma reduce plate elements.

Accuracy – The aforementioned precision for slicing and positioning answers to excessive demands. As we now have pointed out, laser know-how has a couple of benefits over different cutting strategies regarding sure qualities. To put them to work in your favor, it is good to concentrate on them. You can see a 3D STP model uploaded to the platform above. The algorithms detect chopping and bending operations and value the job accordingly. For components with bends, please upload a 3D mannequin in STP format. State-of-the-artwork laser cutters solely want handbook work for setting the parameters.

304H stainless steel belt, SUS304H stainless steel belt, 304H stainless steel belt, 0Cr18Ni9, 304-general model; namely 18/8 stainless steel. The GB grade is 0Cr18Ni9.

Vickers hardness (HV) 370°-420° and Hardness tolerance (HV) ±20°

Relative Keywords:

304h|304 house|304h stainless steel|304h vs 304l|304h stainless|304h chemical composition|304h pipe|304h ss|304h material|inox 304h|sa 240 304h|veh-304hcd-k|304h round bar|304h stainless steel properties|has-304h|304h plate|super 304h chemical composition|cdv2-304hn n|f304h|a240 304h|f-c304h|304h sheet|304h edelstahl|c304h|super 304h composition|lfd-304h|s-304h-cct|est-304h|veh-304hcc-k|304h vs 304|304h pipe suppliers|hlh-304h|304h steel|304h stainless steel round bar|304h stainless steel sheet|304h fittings|304h vs 304l stainless steel|s-304h-ab|304h composition|304h stainless steel composition|304h stainless steel temperature limits|yt-304h|welding 304h stainless steel|304h werkstoff|aisi 304h properties|304h outokumpu|zinsser 304h|cdv2-304hn n pdf|density of 304h stainless steel|

a240 Type 304H widely used material.

Corrosion resistance, heat resistance, good mechanical properties, good processing performance at room temperature such as deep drawing, bending, etc., will not harden after heat treatment, can withstand general rust in the building, and can resist erosion by food processing media (but contains concentrated acid

Corrosion may occur due to high temperature and chloride components), and it can resist organic compounds, dyes and a wide variety of inorganic compounds.

ASTM A240 Stainless Steel 304H Chemical Composition

| Type |

Grade |

ASTM A240 Chemical Composition |

|||||||||

|

ASTM(A240M) |

Others(JIS) |

C |

Si |

Mn |

P |

S |

Ni |

Cr |

Mo |

Others |

|

|

Austenitic Steels |

|||||||||||

|

304H |

0.04/0.10 |

≤0.75 |

≤2.00 |

≤0.045 |

≤0.030 |

8.0/10.5 |

18.0/20.0 |

― |

|||

A240 Type 304L (low carbon), good resistance to nitric acid, and durable for medium temperature and concentration of sulfuric acid, widely used as liquid gas storage tanks, low temperature equipment (304N), appliances and other consumer products, kitchen equipment, hospital equipment, transportation Tools, wastewater treatment equipment.

Alloy 304 (S30400), 304L (S30403), and 304H (S30409) stainless steels are 18% chromium, 8% nickel austenitic alloys, which are the most common and commonly used alloys in the stainless steel family. Because these alloys have one or more of the following properties, they can be used in various applications.

Properties include:

STM A240 TP304H Stainless Steel Plate Physical Properties

| Grade |

Density (kg/m3) |

Elastic Modulus (GPa) |

Mean Coefficient of Thermal Expansion (m/m/0C) |

Thermal Conductivity (W/m.K) |

Specific Heat 0-1000C (J/kg.K) |

Electrical Resistivity (n.m) |

|||

|

0-1000C |

0-3150C |

0-5380C |

at 1000C |

at 5000C |

|||||

|

304H |

8000 |

193 |

17.2 |

17.8 |

18.4 |

16.2 |

21.5 |

500 |

720 |

A high-alloy steel A240 304h that can resist corrosion in the air or in chemically corrosive media. It has a beautiful surface and good corrosion resistance. It does not need to undergo surface treatment such as plating, but exerts its inherent surface properties. It is used in various steels.

One kind, usually called stainless steel.

High alloy steels such as 13 chromium steel and 18-chromium nickel steel are representative of performance.

Others relative stainless keywords:

what is 304h material| 304h |304h plate in houston|304h hardness|304h high temperature|304h hardness brinell|304h pipe houston|what is 304h stainless|aço inox 304h|jis 304h|304h loader|304h larson miller|lnt 304h|304h john deere loader|304h john deere|tube inox 304h|acero inoxidable 304h|soudage inox 304h|gatunek 304h|sa240 gr 304h|304h pipe and fittings|stainless steel 304h flanges|304h stainless steel fittings|f304h vs f304|304h ferrite number|304h filler metal|304 h en minute|304h flat bar|304h flanges|f304h chemical composition|f304h equivalent|304h grain size|304h grade|gd-304h|a240 gr 304h|sus f304h|werkstoff f304h|sa 182 f 304h|a182 f304h chemical composition|a182 f304h temperature|lnm 304h|

From a metallographic point of view, because stainless steel contains chromium, a very thin chromium film is formed on the surface. This film isolates the intruding oxygen from the steel for corrosion resistance.

In order to maintain the inherent corrosion resistance of stainless steel, steel must contain more than 12% chromium

SS 304H Plate Equivalent grades

| STANDARD |

WERKSTOFF NR. |

UNS |

JIS |

AFNOR |

BS |

GOST |

EN |

|

SS 304H |

1.4948 |

S30409 |

– |

– |

– |

– |

– |

304, 304L, and 304H alloys are the most prone to stress corrosion cracking (SSC) among austenitic stainless steels because of their relatively low nickel content.

The conditions that cause stress corrosion cracking are: (1) the presence of halide ions (usually chloride), (2) residual tension, and (3) the temperature exceeds 120°F (49°C).

Cold deformation during alloy forming, stenting into tube sheet, welding operations, etc. can all cause stress.

Annealing and stress relief heat treatment after cold deformation can reduce stress, thus reducing the possibility of halide stress corrosion cracking.

In the environment that may cause intergranular corrosion, it is best to choose low-carbon 304L alloy when working under low-temperature annealing.

AASTM A240 Stainless Steel 304H Plate Mechanical Properties

| Type |

Mechanical Properties for Stainless Steel Plates, Stainless Steel Sheet |

|||||||

|

ASTM(A240M) |

Others(JIS) |

Tensile Properties |

Hardness |

|||||

|

Yield Strength (Mpa) |

Tensile Strength (Mpa) |

Elongation (%) |

HBW |

HRBW |

||||

|

AusteniticSteels |

||||||||

|

304H |

≥205 |

≥515 |

≥40 |

≤201 |

≤92 |

|||

ASTM A240 Type 304H Brushed Stainless Steel Plate

Stainless metallic Rings doesn’t readily corrode, rust or stain with water as odd metallic does. There are totally different grades, and ground A240 SS304L metal plate MILL finishes of stainless steel Rings manufactured and equipped by us to go properly with the surroundings the alloy should endure. Stainless metallic Rings are used the place the properties of metal and corrosion resistance are required. This is kind of course of where the size is completely distinctive and quantity is simply too less.

304h material

Animal figures for coloring 10 items – files arhiv to be used by the laser machine. Advent fire – information arhiv for use by the laser machine. Fusion welding efficiency for Stainless metal 304 is excellent each with and with out fillers. Recommended filler rods and electrodes for stainless-steel 304 is grade 308 chrome steel.

For welding, 904L ought to be within the delicate-annealed or stress relieved situation and be free from scale, grease and markings. Offshore production platforms and different aggressive chloride bearing media.

ASTM A240 TP304H Stainless Steel Plate

When seeking to cut metals in larger thicknesses, please visit our plasma chopping service web page for more info. The positioning accuracy for laser cutting is +/-0.004 inches. Because of the high speed, the thermal effect on the fabric is low. This makes it attainable to chop small holes with a diameter 1/2 of the fabric thickness. The cutting kerf for laser chopping is lower than 0.02 inches. 420 stainless steel Rings are martensitic These 420 chrome steel Rings are characterized by excessive power and excessive wear resistance. The corrosion resistance is restricted and the weldability degrades with increasing energy, i.e. growing carbon content material materials in TP 420 stainless steel Rings.

317L is readily welded by a full range of typical welding procedures except oxyacetylene. After welding 317L may be essential to totally anneal to restore the corrosion resistance lost by sensitization to intergranular corrosion when chromium carbides had been precipitated within the grain boundaries in the weld heat-affected zone. 316/316L is readily welded by a full vary of typical welding procedures besides oxyacetylene. 310 is an austenitic chrome steel developed to be used in high temperature corrosion resistant applications. The alloy resists oxidation as much as 2000°F (1100°C) under mildly cyclic conditions. 304L is readily welded by a full range of standard welding procedures besides oxyacetylene. After welding 304L may be necessary to totally anneal to restore the corrosion resistance misplaced by sensitization to intergranular corrosion when chromium carbides have been precipitated within the grain boundaries within the weld warmth-affected zone.

|what is 304h|rx-304h|304h yield strength|304h vs 316l|p-304h-ab|304h round bar uk|john deere 304h wheel loaders|sharp rp-304h|304h stainless steel data sheet|304h stainless steel chemical composition|john deere 304h loader specs|304h welding wire|304h welding|304h rohre|super 304h welding|304h pipe stock|tole inox 304h|husky c304h air compressor|304h data sheet|304h density|deere 304h specs|p-304h-cct|crane 304h cam|304h carbon content|304h chemistry|304h coefficient of thermal expansion|304h creep strength|deere 304h|deere 304h for sale|304h equivalent|

Gangsteel mainly products are 304h Square tube,304h stainless,304h Rectangular tube,304h seamless pipes,304h seamless tubes,304h welded pipes,304h angle bar,304h H Beam,304h channel beam,304h round bar ,304h cutting part,304h machine part,304H CNC cutting parts,304H water jet cutting parts,304H laser cutting parts and stainless steel 304h. If you have requirement, please contact us by email admin@gangsteel.com