1.4404 chrome steel

We produce ASTM/ASME Grade 304, Grade 304L,304h, 316, 316L, 316H, 316TI, 321, 321H, 309S, 309H, 310S, 310H, 410S, 2205, 904L, 2507, 254, gh3030, 625, 253MA, S30815, 317L, Type 317, 316lN, 8020, 800, 800H, C276, S32304 and others special requirement stainless steel grade.

Content

The minimum 10.5% chromium in stainless steels offers resistance to roughly 700 °C (1,300 °F), while 16% chromium supplies resistance up to roughly 1,200 °C (2,200 °F). Type 304, the most typical grade of stainless steel with 18% chromium, is proof against roughly 870 °C (1,600 °F). Other gases, corresponding to sulfur dioxide, hydrogen sulfide, carbon monoxide, chlorine, additionally assault stainless steel. Resistance to other gases depends on the type of fuel, the temperature, and the alloying content of the chrome steel. Stainless steels have a long history of utility involved with water because of their excellent corrosion resistance.

Austenitic Stainless Steel

Unprotected carbon metal rusts readily when exposed to a combination of air and moisture. The ensuing iron oxide floor layer is porous and fragile. In addition, as iron oxide occupies a larger volume than the unique metal, this layer expands and tends to flake and fall away, exposing the underlying metal to further attack. This passive film prevents additional corrosion by blocking oxygen diffusion to the steel floor and thus prevents corrosion from spreading into the bulk of the metallic. This film is self-repairing, even when scratched or briefly disturbed by an upset condition within the surroundings that exceeds the inherent corrosion resistance of that grade.

Stainless steel is now used as one of the supplies for tramlinks, along with aluminium alloys and carbon steel. Duplex grades are typically most well-liked thanks to their corrosion resistance and higher power, allowing a discount of weight and a long life in maritime environments.

- Other gases, corresponding to sulfur dioxide, hydrogen sulfide, carbon monoxide, chlorine, also assault stainless-steel.

- Type 304, the most common grade of stainless-steel with 18% chromium, is immune to approximately 870 °C (1,600 °F).

- The minimal 10.5% chromium in stainless steels offers resistance to roughly 700 °C (1,300 °F), while sixteen% chromium offers resistance up to approximately 1,200 °C (2,200 °F).

Stock Thickness: 0.1-200.0mm

Production thickness: 0.5.0-200mm

Width: 600-3900mm

Length: 1000-12000mm

Grade:

200 series: 201,202

300 series: 301,304,304L,304H,309,309S,310S,316L,316Ti,321,321H,330

400 series: 409,409l,410,420J1,420J2,430,436,439,440A/B/C

Duplex: 329,2205,2507,904L,2304

Surface: No.1,1D,2D,2B,NO.4/4K/hairline,satin,6k,BA,mirror/8K

At elevated temperatures, all metals react with scorching gases. The most typical excessive-temperature gaseous combination is air, of which oxygen is essentially the most reactive element.

What thickness is 18 gauge steel?

When using stainless steel cookware, know that deeply scratched and pitted pans can cause metals (nickel and chromium) to migrate into food in trace amounts. These are not toxic elements, so there is not really cause for concern unless you have a specific allergy or sensitivity.

All chrome steel is NOT necessarily non-magnetic. It is frequent for stainless to pick up iron ions from the die and gear used through the stamping course of.

After a 500 ton press squeezes the nickel it modifications the distribution of the nickel. The identical is true where the die cuts the stainless increasing the chance that rust will finally occur there. All chrome steel is magnetic except austenitic stainless-steel which is actually 300 collection stainless such as 304 and 316. However, 300 collection stainless is non-magnetic solely after it is freshly formed.

Is 316 Stainless Steel Worth The Extra Cost Over 304?

Applications embody a variety of circumstances including plumbing, potable water and wastewater therapy, desalination, and brine remedy. Types 304 and 316 stainless steels are standard supplies of construction involved with water. However, with rising chloride contents, larger alloyed stainless steels corresponding to Type 2205 and tremendous austenitic and super duplex stainless steels are used. Unlike carbon metal, stainless steels don’t undergo uniform corrosion when exposed to moist environments.

We have thousands tons stock of stainless steel sheet and coil with various size and grade,mainly include austenitic stainless steel, martens stainless steel (including precipitation hardened stainless steel sheet & coil), ferritic stainless steel, and duplex stainless steel.

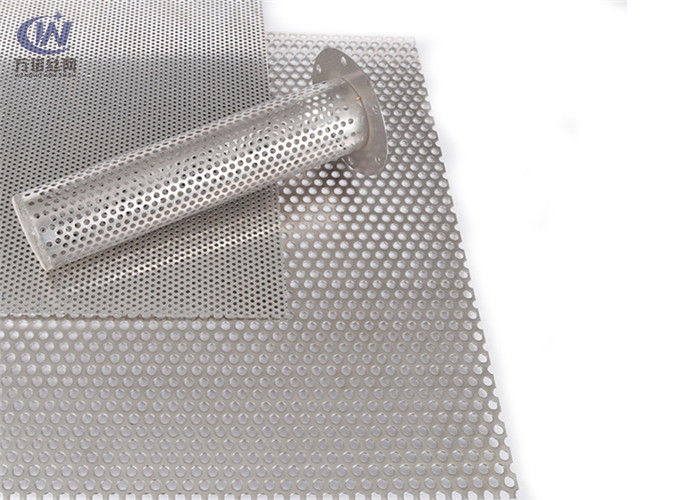

Characteristics of Stainless Steel Sheet and Plate:

High corrosion resistance

High strength

High toughness and impact resistance

Temperature resistance

High workability, including machining, stamping, fabricating and welding

Smooth surface finish that can be easily clean