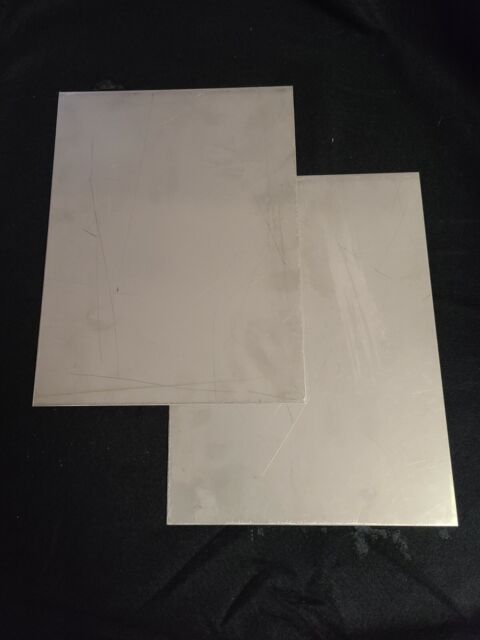

0.8 mm stainless steel sheet

We produce ASTM/ASME Grade 304, Grade 304L,304h, 316, 316L, 316H, 316TI, 321, 321H, 309S, 309H, 310S, 310H, 410S, 2205, 904L, 2507, 254, gh3030, 625, 253MA, S30815, 317L, Type 317, 316lN, 8020, 800, 800H, C276, S32304 and others special requirement stainless steel grade.

Content

How can I tell if my stainless steel is 304 or 316?

This breakthrough attributes to Taiyuan Iron and Steel Group Co., LTD (TISCO), a steel mill with a history of 84 years in north China’s Shanxi Province. The thickness of this kind of stainless steel sheet is 0.02 millimeters, or one-fourth of a sheet of A-4 paper. It is so thin that it can be torn by hands.

However, with growing chloride contents, larger alloyed stainless steels corresponding to Type 2205 and super austenitic and super duplex stainless steels are used. Unlike carbon metal, stainless steels don’t undergo uniform corrosion when uncovered to wet environments. Unprotected carbon metal rusts readily when exposed to a combination of air and moisture.

Applications embrace a variety of circumstances including plumbing, potable water and wastewater treatment, desalination, and brine therapy. Types 304 and 316 stainless steels are commonplace supplies of construction involved with water.

Galvanic Corrosion

When the 2 surfaces are of the same material, these uncovered surfaces can easily fuse. Separation of the two surfaces may end up in floor tearing and even complete seizure of metal components or fasteners. Type 304 and Type 316 stainless steels are unaffected weak bases similar to ammonium hydroxide, even in high concentrations and at excessive temperatures. The similar grades uncovered to stronger bases corresponding to sodium hydroxide at excessive concentrations and excessive temperatures will doubtless expertise some etching and cracking. Increasing chromium and nickel contents provide increased resistance.

- Type 304, the commonest grade of stainless steel with 18% chromium, is proof against approximately 870 °C (1,600 °F).

- Resistance to different gases relies on the kind of fuel, the temperature, and the alloying content of the stainless steel.

- The minimum 10.5% chromium in stainless steels supplies resistance to roughly seven-hundred °C (1,300 °F), while sixteen% chromium supplies resistance up to roughly 1,200 °C (2,200 °F).

- Type 304, with its chromium-nickel content material and low carbon, is essentially the most versatile and widely used of the austenitic stainless steels.

- Other gases, corresponding to sulfur dioxide, hydrogen sulfide, carbon monoxide, chlorine, additionally assault stainless steel.

Our stainless production range

They can’t be strengthened by cold work to the same degree as austenitic stainless steels. The invention of stainless-steel adopted a series of scientific developments, starting in 1798 when chromium was first proven to the French Academy by Louis Vauquelin.

In the early 1800s, James Stodart, Michael Faraday, and Robert Mallet noticed the resistance of chromium-iron alloys (“chromium steels”) to oxidizing brokers. Robert Bunsen found chromium’s resistance to robust acids. The corrosion resistance of iron-chromium alloys may have been first acknowledged in 1821 by Pierre Berthier, who famous their resistance towards attack by some acids and advised their use in cutlery. Stainless gets its non corrosive properties from the chromium within the alloy. It’s created when oxygen combines with the chrome within the stainless to kind chrome oxide which is extra commonly called “ceramic”.

Alloy content material usually is on the order of 15-30% so the price of chrome steel is notably higher than carbon/alloy steels. Stainless metal can also be not usually used where very high power or hardness is required.

What is the best tool for cutting sheet metal?

Surgical stainless steel is hypoallergenic and the industry-standard in body piercing jewelry. Surgical stainless steel should never cause an allergic reaction turning your skin green, and it should never make your skin breakout.

Type 304, with its chromium-nickel content material and low carbon, is the most versatile and widely used of the austenitic stainless steels. Type 304 alloys are all modifications of the 18% chromium, 8% nickel austenitic alloy.

We have thousands tons stock of stainless steel sheet and coil with various size and grade,mainly include austenitic stainless steel, martens stainless steel (including precipitation hardened stainless steel sheet & coil), ferritic stainless steel, and duplex stainless steel.

Characteristics of Stainless Steel Sheet and Plate:

High corrosion resistance

High strength

High toughness and impact resistance

Temperature resistance

High workability, including machining, stamping, fabricating and welding

Smooth surface finish that can be easily clean