1.4404 aisi 316l stainless-steel provider

We produce ASTM/ASME Grade 304, Grade 304L,304h, 316, 316L, 316H, 316TI, 321, 321H, 309S, 309H, 310S, 310H, 410S, 2205, 904L, 2507, 254, gh3030, 625, 253MA, S30815, 317L, Type 317, 316lN, 8020, 800, 800H, C276, S32304 and others special requirement stainless steel grade.

Content

The minimal 10.5% chromium in stainless steels offers resistance to approximately seven-hundred °C (1,300 °F), while sixteen% chromium provides resistance as much as approximately 1,200 °C (2,200 °F). Type 304, the most common grade of stainless-steel with 18% chromium, is proof against approximately 870 °C (1,600 °F).

Thus, there are quite a few grades of stainless-steel with various chromium and molybdenum contents to go well with the surroundings the alloy must endure. Stainless steel remains stainless, or doesn’t rust, because of the interaction between its alloying components and the surroundings. Stainless steel incorporates iron, chromium, manganese, silicon, carbon and, in lots of cases, important quantities of nickel and molybdenum. These parts react with oxygen from water and air to kind a very skinny, stable movie that consists of such corrosion merchandise as metallic oxides and hydroxides.

Robert Bunsen found chromium’s resistance to strong acids. The corrosion resistance of iron-chromium alloys might have been first recognized in 1821 by Pierre Berthier, who famous their resistance towards attack by some acids and advised their use in cutlery. The addition of nitrogen also improves resistance to pitting corrosion and will increase mechanical power.

Chanson,TISCO,BAOSTEEL,POSCO,JISCO,LISCO

Our stainless production range

The ease of welding largely depends on the kind of stainless-steel used. Austenitic stainless steels are the easiest to weld by electric arc, with weld properties just like these of the base metallic (not cold-labored). Post-weld heat remedy is sort of at all times required while preheating earlier than welding can be needed in some instances. At elevated temperatures, all metals react with sizzling gases.

- Stainless steels have an extended history of application in touch with water as a result of their wonderful corrosion resistance.

- Type 304, the commonest grade of stainless steel with 18% chromium, is proof against approximately 870 °C (1,600 °F).

- The minimal 10.5% chromium in stainless steels provides resistance to roughly seven hundred °C (1,300 °F), whereas 16% chromium offers resistance up to roughly 1,200 °C (2,200 °F).

- Other gases, corresponding to sulfur dioxide, hydrogen sulfide, carbon monoxide, chlorine, additionally attack stainless steel.

How do you mirror stainless steel?

Both steels are durable and provide excellent resistance to corrosion and rust. 304 stainless steel is the most versatile and widely used austenitic stainless steel in the world, due to its corrosion resistance. If your application uses milder acids or does not contain salt exposure, stainless 304 is perfect.

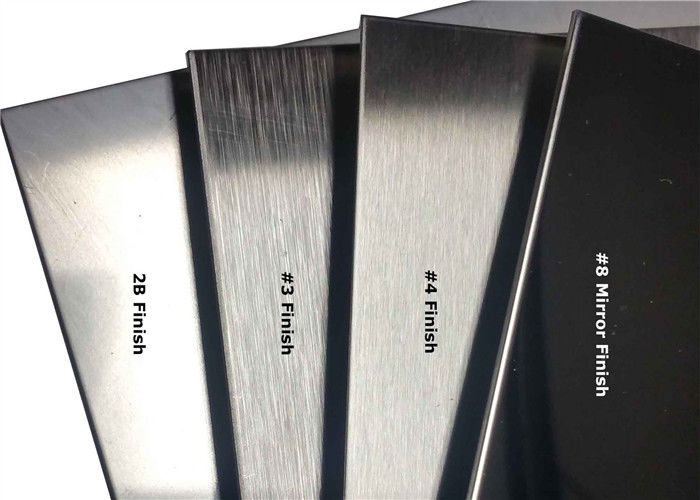

Standard Finishes

Austenitic stainless-steel is the most important household of stainless steels, making up about two-thirds of all chrome steel production (see manufacturing figures under). They possess an austenitic microstructure, which is a face-centered cubic crystal structure. Thus, austenitic stainless steels usually are not hardenable by warmth treatment since they possess the identical microstructure at all temperatures. The second commonest grade (after 304); for meals and surgical chrome steel uses; Alloy addition of molybdenum prevents specific types of corrosion.

Does toothpaste remove scratches from stainless steel?

The difference between CRS and 304 stainless steel is that CRS is a process and 304 is an alloy. Steel, hot or cold rolled, will rust and corrode. It is used in applications where that is not a consideration. Stainless steel is an alloy with chromium and nickel that prevents rust and corrosion.

Chromium plays a dominant position in reacting with oxygen to kind this corrosion product film. In reality, all stainless steels by definition comprise no less than 10 % chromium. A brushed finish is vulnerable to break. Brushed finishes additionally typically have a detrimental impact on corrosion resistance. In particular the brushed texture limits the flexibility of fluid to bead on the material surface.

Under high contact-drive sliding, this oxide can be deformed, damaged, and faraway from parts of the element, exposing the naked reactive metal. When the two surfaces are of the identical materials, these uncovered surfaces can easily fuse. Separation of the two surfaces can lead to surface tearing and even complete seizure of steel parts or fasteners.

We have thousands tons stock of stainless steel sheet and coil with various size and grade,mainly include austenitic stainless steel, martens stainless steel (including precipitation hardened stainless steel sheet & coil), ferritic stainless steel, and duplex stainless steel.

Characteristics of Stainless Steel Sheet and Plate:

High corrosion resistance

High strength

High toughness and impact resistance

Temperature resistance

High workability, including machining, stamping, fabricating and welding

Smooth surface finish that can be easily clean