1.4509 aisi 441 stainless steel supplier

We produce ASTM/ASME Grade 304, Grade 304L,304h, 316, 316L, 316H, 316TI, 321, 321H, 309S, 309H, 310S, 310H, 410S, 2205, 904L, 2507, 254, gh3030, 625, 253MA, S30815, 317L, Type 317, 316lN, 8020, 800, 800H, C276, S32304 and others special requirement stainless steel grade.

The addition of nitrogen additionally improves resistance to pitting corrosion and increases mechanical energy. Thus, there are numerous grades of stainless steel with various chromium and molybdenum contents to go well with the environment the alloy must endure.

Is 304 stainless steel rust proof?

Type 409: One of the least expensive Stainless grades due to its decreased chromium content. This type should only be used for interior or exterior parts in non-critical corrosive environments. Typical applications include muffler stock.

These steels are recognized to have glorious weldability and don’t need any submit-weld remedy. Conventional arc welding strategies that can be utilized on austenitic chrome steel include shielded metallic, plasma, fuel metallic, fuel tungsten, and submerged welding.

Types 304 and 316 stainless steels are commonplace materials of development in touch with water. However, with rising chloride contents, larger alloyed stainless steels corresponding to Type 2205 and super austenitic and tremendous duplex stainless steels are used. Improve performance in rugged environments with 303 stainless steel plate from Dix Metals. A non-magnetic, austenitic chrome steel that isn’t hardenable by warmth remedy, 303 stainless-steel plate offers good climate resistance, toughness and forming properties. Comprised of chromium, nickel, chrome steel and other alloys, this material type is designed to exhibit improved machinability whereas maintaining robust mechanical and anti-corrosion properties.

What is the difference between 304 and 410 stainless steel?

Both steels are durable and provide excellent resistance to corrosion and rust. 304 stainless steel is the most versatile and widely used austenitic stainless steel in the world, due to its corrosion resistance. If your application uses milder acids or does not contain salt exposure, stainless 304 is perfect.

Width

Our stainless production range

- Types 304 and 316 stainless steels are normal materials of development in contact with water.

- Applications include a range of circumstances together with plumbing, potable water and wastewater remedy, desalination, and brine treatment.

- However, with increasing chloride contents, higher alloyed stainless steels such as Type 2205 and super austenitic and tremendous duplex stainless steels are used.

- Improve efficiency in rugged environments with 303 stainless-steel plate from Dix Metals.

- Stainless steels have a protracted history of application involved with water because of their wonderful corrosion resistance.

Its low carbon content material makes it suitable for most welding operations which are widespread in building and different industries. 304L also provides for glorious rust resistance and low intergranular corrosion. 304, like all austenitic steels, is non-magnetic in nature, and it additionally options low electrical and thermal conductivity. It also is acknowledged for its greater corrosion resistance than most other chrome steel alloys. Alloy 303 is a non-magnetic, austenitic stainless steel that is not hardenable by heat therapy.

Welding Stainless Steels

Stainless steels have a protracted historical past of application in touch with water as a result of their wonderful corrosion resistance. Applications embrace a variety of conditions including plumbing, potable water and wastewater therapy, desalination, and brine remedy.

Small additions of cerium and yttrium improve the adhesion of the oxide layer on the surface. Unlike carbon metal, stainless steels do not endure uniform corrosion when exposed to moist environments. Unprotected carbon metal rusts readily when uncovered to a mixture of air and moisture. The resulting iron oxide floor layer is porous and fragile.

Austenitic stainless steel is the largest household of stainless steels, making up about two-thirds of all stainless-steel production (see manufacturing figures under). They possess an austenitic microstructure, which is a face-centered cubic crystal construction. Thus, austenitic stainless steels are not hardenable by warmth remedy since they possess the identical microstructure in any respect temperatures. When selecting a stainless steel that must endure corrosive environments, austenitic stainless steels are typically used. Possessing glorious mechanical properties, the high quantities of nickel and chromium in austenitic stainless steels additionally provide outstanding corrosion resistance.

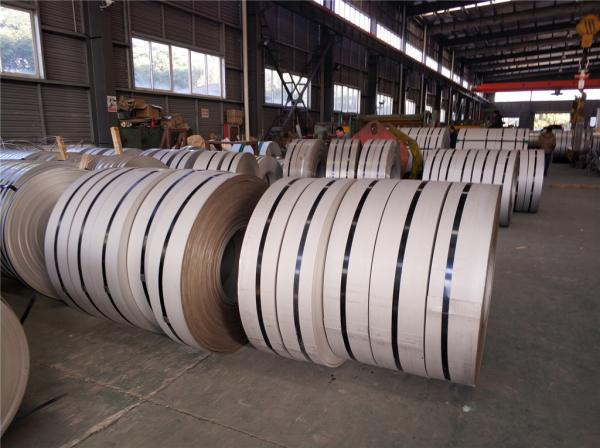

We have thousands tons stock of stainless steel sheet and coil with various size and grade,mainly include austenitic stainless steel, martens stainless steel (including precipitation hardened stainless steel sheet & coil), ferritic stainless steel, and duplex stainless steel.

Characteristics of Stainless Steel Sheet and Plate:

High corrosion resistance

High strength

High toughness and impact resistance

Temperature resistance

High workability, including machining, stamping, fabricating and welding

Smooth surface finish that can be easily clean