1.4034 aisi stainless steel provider

We produce ASTM/ASME Grade 304, Grade 304L,304h, 316, 316L, 316H, 316TI, 321, 321H, 309S, 309H, 310S, 310H, 410S, 2205, 904L, 2507, 254, gh3030, 625, 253MA, S30815, 317L, Type 317, 316lN, 8020, 800, 800H, C276, S32304 and others special requirement stainless steel grade.

Content

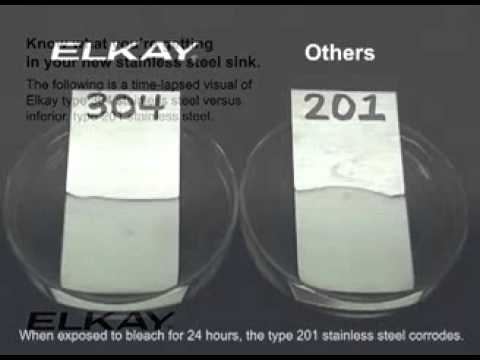

In addition, as iron oxide occupies a larger quantity than the unique steel, this layer expands and tends to flake and fall away, exposing the underlying metal to additional assault. This passive movie prevents further corrosion by blocking oxygen diffusion to the metal surface and thus prevents corrosion from spreading into the majority of the steel. This film is self-repairing, even when scratched or temporarily disturbed by an upset condition within the setting that exceeds the inherent corrosion resistance of that grade.

Replacing some carbon in martensitic stainless steels by nitrogen is a current development.[when? ] The restricted solubility of nitrogen is elevated by the strain electroslag refining (PESR) course of, by which melting is carried out under high nitrogen stress. Steel containing as much as zero.four% nitrogen has been achieved, leading to higher hardness and power and better corrosion resistance. As PESR is dear, lower however important nitrogen contents have been achieved using the standard argon oxygen decarburization (AOD) course of. Ferritic stainless steels possess a ferrite microstructure like carbon steel, which is a body-centered cubic crystal construction, and include between 10.5% and 27% chromium with very little or no nickel.

Applications include a range of conditions including plumbing, potable water and wastewater therapy, desalination, and brine therapy. Types 304 and 316 stainless steels are standard supplies of development in touch with water.

What grade stainless steel is food grade?

Food grade stainless steel is steel that met all criteria to be deemed safe for food preparation, storage and dining. The most common food grade stainless steel is Type 304. But 304 grade stainless steel also goes by another name or code, 18/8 and 18/10 stainless steel.

Our stainless production range

Unprotected carbon metal rusts readily when uncovered to a mixture of air and moisture. The ensuing iron oxide floor layer is porous and fragile.

- Type 304, the most typical grade of stainless steel with 18% chromium, is immune to roughly 870 °C (1,600 °F).

- The minimum 10.5% chromium in stainless steels provides resistance to roughly 700 °C (1,300 °F), whereas 16% chromium supplies resistance as much as roughly 1,200 °C (2,200 °F).

- Other gases, similar to sulfur dioxide, hydrogen sulfide, carbon monoxide, chlorine, additionally assault stainless steel.

- Resistance to different gases depends on the type of gas, the temperature, and the alloying content of the stainless steel.

Choosing The Best Metals Analysis Method For Eaf Steel Manufacturing

The chromium combines with the oxygen before the iron is ready to which types a chromium oxide layer. This layer may be very corrosion resistant which prevents rust formation and protects the underlying metallic. On the opposite hand, ferritic or martensitic stainless steels may be susceptible to rust because they comprise less chromium.

Stainless metal is simpler to maintain and doesn’t require a protective coating, however is often dearer that its carbon various. To be considered chrome steel, 10.5 % chromium (or extra) have to be present in the steel. Adding chromium to the combination creates steel which is highly resistant to rust and corrosion.

How To Prevent Stainless Steel From Rusting?

However, with growing chloride contents, larger alloyed stainless steels corresponding to Type 2205 and super austenitic and super duplex stainless steels are used. Unlike carbon steel, stainless steels don’t endure uniform corrosion when exposed to wet environments.

We have thousands tons stock of stainless steel sheet and coil with various size and grade,mainly include austenitic stainless steel, martens stainless steel (including precipitation hardened stainless steel sheet & coil), ferritic stainless steel, and duplex stainless steel.

Characteristics of Stainless Steel Sheet and Plate:

High corrosion resistance

High strength

High toughness and impact resistance

Temperature resistance

High workability, including machining, stamping, fabricating and welding

Smooth surface finish that can be easily clean