1.4408 aisi chrome steel

We produce ASTM/ASME Grade 304, Grade 304L,304h, 316, 316L, 316H, 316TI, 321, 321H, 309S, 309H, 310S, 310H, 410S, 2205, 904L, 2507, 254, gh3030, 625, 253MA, S30815, 317L, Type 317, 316lN, 8020, 800, 800H, C276, S32304 and others special requirement stainless steel grade.

Content

Category: Metal Man Knows

The phenomenon of labor hardening is important in the design and fabrication of sheet metal car panels. It is both an issue for, and an asset to, anyone who has to repair sheet metallic. The asset is that the areas the place dies have deformed sheet metallic from its authentic flat state provide much of the mandatory panel power in physique design. The drawback is that when a panel have to be straightened as a result of impression harm, it’ll have hardened in a number of places and in ways that may make it tough to straighten it without inducing extra deformations. So let’s talk gauge… There three basic gauges used in metal tube panels typically 16 ga, 14 ga, and 10 ga.

Traditional metallic ending methods are out of the question because files are inclined to skate over their excessive carbon steel or, if they do reduce, they weaken the panels grievously or reduce right by way of them. Even disk sanding them could be a hair-elevating experience in case you are not tremendous cautious. Instead, the steel on either aspect of the original bend will in the end deform earlier than the bend is completely removed.

In that barbaric course of, they produce stretching, further deformation and work hardening that are tough to appropriate later. Automotive sheet steel as soon as ran within the vary of 18-gauge, which was 48 thousandths of an inch thick (actually 0.0478 inch). 20-gauge turned widespread in more recent times, and this meant zero.0359-inch-thick metallic—still a lot to work with in-bumping and metallic finishing. The first is that the alloys used to make it are troublesome to type in restore situations as a result of they’re relatively onerous (high carbon) and have very little elasticity. Check out the decklids on some trendy minivans and hatchbacks in any car parking zone and notice the dents and creases left by folks’s arms when they have been overly energetic in slamming them shut.

- The problem is that when a panel have to be straightened as a result of influence damage, it’s going to have hardened in a number of places and in ways that could make it troublesome to straighten it with out inducing further deformations.

- So let’s speak gauge… There three primary gauges used in metal tube panels sometimes 16 ga, 14 ga, and 10 ga.

- The asset is that the areas the place dies have deformed sheet steel from its unique flat state present much of the required panel strength in physique design.

- The phenomenon of labor hardening is crucial within the design and fabrication of sheet metal car panels.

- It is each an issue for, and an asset to, anyone who has to restore sheet metal.

Stock Thickness: 0.1-200.0mm

Production thickness: 0.5.0-200mm

Width: 600-3900mm

Length: 1000-12000mm

Grade:

200 series: 201,202

300 series: 301,304,304L,304H,309,309S,310S,316L,316Ti,321,321H,330

400 series: 409,409l,410,420J1,420J2,430,436,439,440A/B/C

Duplex: 329,2205,2507,904L,2304

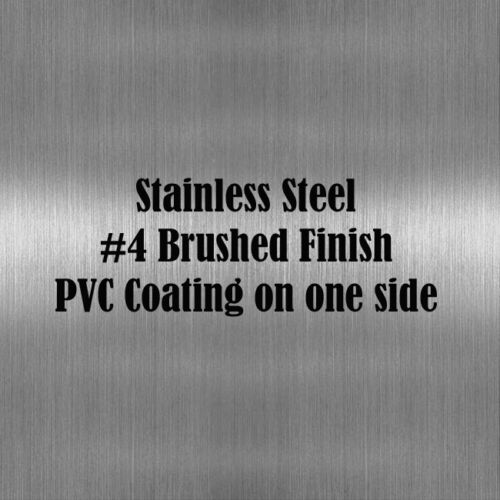

Surface: No.1,1D,2D,2B,NO.4/4K/hairline,satin,6k,BA,mirror/8K

Corrosion harm must be detected by investigation that employs bodily selecting and probing, along with visual inspection. This could appear brutal, however every kind of corrosion could be lurking under seemingly sound paint.

Unfortunately, the act of straightening a deformed and stretched panel entails hammering on its ridges and channels, either directly over a dolly block or adjoining to at least one. This often ends in additional stretching the metal as a result of metallic is made thinner when it’s hammered on. This can create a troublesome combination of defects to deal with with proper repairs. The two most common types of sheet metallic damage, corrosion and impression, should be dealt with in very particular methods.

How much does a sheet of 14 gauge steel weight?

14 AWG Speaker Wire can handle up to 750 watts of power at 20 ft Cable Runs: 14 guage speaker wire can carry up to 750 watts of power with 20 ft of speaker wire and a 4 ohm speaker load with 37 watts lost at the speaker terminals.

Certainly, the place paint has bubbled and/or blistered, there’s good trigger to suspect underlying corrosion. Where body contours appear to be modified, or where panels are 1/eight inch thick, or more, you will often discover rust, fiberglass bandages, pop riveted roofing tin and any method of different mischief beneath the floor.

What is the thickest gauge steel?

Everything You Need to Know About Gauge of Steel The rating for steel gauge may seem backward: the smaller the number, the thicker the steel. 7 gauge steel, for example, is much thicker than 12 gauge steel. And the thickness makes a difference—the thicker the steel, the stronger it is.

Gauges work like this; the smaller the number the thicker the metal. 16ga steel is .065” inches thick, that’s about 1/sixteenth of an inch thick. 14 gauge compared is .083 inches thick which doesn’t sound like a lot except it’s virtually 30% thicker (27.6% to be actual).

We have thousands tons stock of stainless steel sheet and coil with various size and grade,mainly include austenitic stainless steel, martens stainless steel (including precipitation hardened stainless steel sheet & coil), ferritic stainless steel, and duplex stainless steel.

Characteristics of Stainless Steel Sheet and Plate:

High corrosion resistance

High strength

High toughness and impact resistance

Temperature resistance

High workability, including machining, stamping, fabricating and welding

Smooth surface finish that can be easily clean