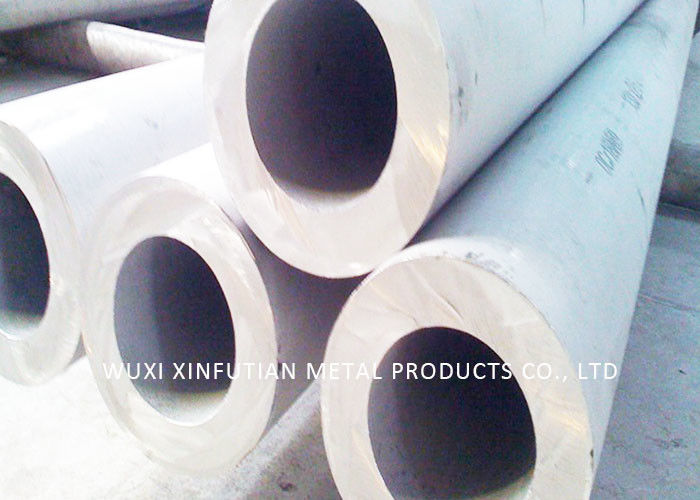

1 inch stainless steel pipe worth

We produce ASTM/ASME Grade 304, Grade 304L,304h, 316, 316L, 316H, 316TI, 321, 321H, 309S, 309H, 310S, 310H, 410S, 2205, 904L, 2507, 254, gh3030, 625, 253MA, S30815, 317L, Type 317, 316lN, 8020, 800, 800H, C276, S32304 and others special requirement stainless steel grade.

By subjecting the product to an extra ageing process, it’s possible to further increase the tensile energy of the product while retaining its excessive levels of ductility. Whilst duplex stainless steels are thought of resistant to stress corrosion cracking, they are not as immune to this type of assault as ferritic stainless steels. However, the corrosion resistance of the least resistant duplex stainless steels is bigger than that for probably the most generally used grades of stainless steels, i.e. 304 and 316. In addition, alloy C-276 resists formation of grain boundary precipitates within the weld warmth affected zone making it useful for many chemical processes in the as-welded situation. This alloy has wonderful resistance to pitting and stress corrosion cracking.

The chromium, tungsten, nitrogen and molybdenum content material in duplex and tremendous duplex create the resistance to crevice corrosion and chloride pitting that makes these materials so well-liked. These steels even have resistance to chloride stress corrosion which is considerably higher than austenitic grades, without sacrificing on durability or ductility.

Alloy 254, is a high alloy austenitic stainless-steel equipped in the hot labored and annealed condition. Significant additions of Mo, Ni and Cu gives this alloy an excellent resistance to pitting and crevice corrosion, particularly in environments containing halide ions e.g. chloride, bromide and fluoride solutions. Duplex and tremendous duplex belong to a household of stainless steels that are characterised by a mix of simple fabrication, excessive power and glorious corrosion resistance. This group of supplies is most similar to ferritic and carbon steel, however it has some bodily properties according to these present in austenitic stainless steel. Grade 316 has especially better resistance to salt and chloride pitting.

Marlin Steel’s Stainless Steel Solutions

Stock Thickness: 0.1-200.0mm

Production thickness: 0.5.0-200mm

Width: 600-3900mm

Length: 1000-12000mm

Grade:

200 series: 201,202

300 series: 301,304,304L,304H,309,309S,310S,316L,316Ti,321,321H,330

400 series: 409,409l,410,420J1,420J2,430,436,439,440A/B/C

Duplex: 329,2205,2507,904L,2304

Surface: No.1,1D,2D,2B,NO.4/4K/hairline,satin,6k,BA,mirror/8K

What is ferrite content in duplex stainless steel?

Alloy additions also suppress (lower) the melting range. Pure iron (Fe) has a fixed melting point of 1535°C, chromium (Cr) 1890°C and nickel (Ni) 1453°C compared to a range of 1400-1450 °C for type 304 stainless steel.

- Ferralium® 255 is a super duplex stainless-steel supplied in the hot worked, annealed and pickled situation.

- Duplex 2507 is a super duplex chrome steel designed for purposes which demand distinctive strength and corrosion resistance.

- The molybdenum gives 316 higher overall corrosion resistant properties than Grade 304, notably higher resistance to pitting and crevice corrosion in chloride environments.

- It achieves higher strengths than other various corrosion resistant alloys, offering the potential to reduce section measurement and therefore weight and price.

Pitting corrosion can happen when chrome steel alloys, similar to grade 304 chrome steel, come into contact with salt-wealthy sea breezes and seawater. Chloride resistant metals, like grade 16 stainless steel, are important to use for naval purposes or anything concerned with chloride. Alloy 825 is a nickel-iron-chromium alloy with additions of molybdenum, copper and titanium (NiCr21Mo), equipped within the scorching worked and annealed condition. Ferralium® 255 – FG46 is a super duplex stainless-steel supplied in the pressure hardened situation (Condition S).

However, the nearer grade 304 chrome steel reaches its melting point, the more tensile energy it loses. Grade 316 is a popular alloy of stainless-steel with a melting range of two,500 °F – 2,550 °F (1,371 °C – 1,399 °C). As an austenitic stainless steel alloy, it has qualities corresponding to excessive energy, corrosion resistance, and high concentrations of chromium and nickel.

It is optimised for fastener applications, matching the mechanical properties of the B7 grade alloy carbon steel which is most commonly used for prime-stress bolting purposes. Ferralium® 255 – 3AF is a super duplex chrome steel supplied in the hot worked, annealed and aged condition.

Super Duplex 2507

Sanmac® 2205 is a 22% Cr duplex stainless steel with improved machinability as commonplace. Hastelloy C276 is a nickel-molybdenum-chromium superalloy with an addition of tungsten designed to have glorious corrosion resistance in a wide range of extreme environments. The high nickel and molybdenum contents make the nickel steel alloy particularly proof against pitting and crevice corrosion in decreasing environments while chromium conveys resistance to oxidizing media. The low carbon content minimizes carbide precipitation throughout welding to keep up corrosion resistance in as-welded buildings. This nickel alloy is resistant to the formation of grain boundary precipitates within the weld warmth-affected zone, thus making it suitable for many chemical course of utility in an as welded condition.

We have thousands tons stock of stainless steel sheet and coil with various size and grade,mainly include austenitic stainless steel, martens stainless steel (including precipitation hardened stainless steel sheet & coil), ferritic stainless steel, and duplex stainless steel.

Characteristics of Stainless Steel Sheet and Plate:

High corrosion resistance

High strength

High toughness and impact resistance

Temperature resistance

High workability, including machining, stamping, fabricating and welding

Smooth surface finish that can be easily clean