1.4404 aisi 316l stainless steel provider

We produce ASTM/ASME Grade 304, Grade 304L,304h, 316, 316L, 316H, 316TI, 321, 321H, 309S, 309H, 310S, 310H, 410S, 2205, 904L, 2507, 254, gh3030, 625, 253MA, S30815, 317L, Type 317, 316lN, 8020, 800, 800H, C276, S32304 and others special requirement stainless steel grade.

Content

Type 316L Stainless Steel is an improved corrosion resistant Chrome-Nickel steel alloy with a high content of Molybdenum. The material is non-magnetic, even after a number of chilly forming operations.

Steel Bar, Round Bar, Stainless Steel producer / supplier in China, offering Mat. No. 1.4441 AISI 316lvm Steel Bar, Black Anodized Aluminium Thermal Heat Sink with Competitive Price and High Quality, Electronic Polishing Zinc Alloy Die Casting Parts Made in China and so forth.

The nickel content material permits the austenitic structure that supports corrosion resistance. In truth, the lacking second phase – e.g. martensite derived from the deformation or ferrite – promotes corrosion resistance.

Stock Thickness: 0.1-200.0mm

Production thickness: 0.5.0-200mm

Width: 600-3900mm

Length: 1000-12000mm

Grade:

200 series: 201,202

300 series: 301,304,304L,304H,309,309S,310S,316L,316Ti,321,321H,330

400 series: 409,409l,410,420J1,420J2,430,436,439,440A/B/C

Duplex: 329,2205,2507,904L,2304

Surface: No.1,1D,2D,2B,NO.4/4K/hairline,satin,6k,BA,mirror/8K

- The material is non-magnetic, even after a number of cold forming operations.

- Type 316L Stainless Steel is an improved corrosion resistant Chrome-Nickel metal alloy with a high content of Molybdenum.

- It is austenitic Stainless Steel for implants, with high corrosion resistance, based on ISO 5832/1, F-138 Vacuum melt grade (VAR).

- Type 316L isn’t a typical freemachining grade and subsequently not really helpful for difficult excessive pace machining.

- Type 316L is used for surgical devices, fracture fixation gadgets, screws for implants and many more comparable applications.

Ferritic stainless steels are iron/chromium or iron/chromium/molybdenum alloys with a chromium content between 10.5 and 28 % and a carbon content material not exceeding zero.08 %. These steels normally include no nickel and harden only by chilly deformation. Implant metal with improved corrosion resistance in comparison with AISI 316L. Regarded as “Medical Grade”, this Stainless Steel 316 is vacuum melted to attain the extraordinarily high levels of purity and “cleanliness” required for surgical implants. It has wonderful resistance in physiological environments, to basic and intergranular corrosion, to pitting and crevice corrosion.

Valbruna Stainless Steel throughout the new bridge in Genova Click here to learn the information. Because of the wonderful surface end, purposes additionally embrace use in high precision electronics. knee joints, and pins, bone and nail plates, internal fixation units, dental implants, staples.

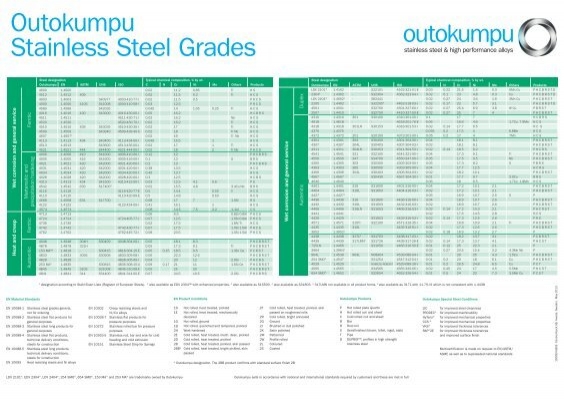

Stainless Steels

316LVM (low carbon vacumm melt) stainless-steel, thought to be a medical grade, this stainless-steel is vacuum melted to attain excessive ranges of purity and cleanliness. It has wonderful resistance to both general and intergranular corrosion, and pitting and crevice corrosion.

Aisi 420c , En 1.4034 , Din X46cr13 Stainless Steel Wire And Round Bar

Type 316L isn’t a typical freemachining grade and subsequently not really helpful for difficult excessive pace machining. It is austenitic Stainless Steel for implants, with high corrosion resistance, based on ISO 5832/1, F-138 Vacuum melt grade (VAR). Type 316L is used for surgical instruments, fracture fixation devices, screws for implants and lots of extra comparable functions. Among the steel types, austenitic steels are the preferred and are used most. Apart from a chromium content material of 17 %, they include nickel and maybe molybdenum, titanium or niobium components.

We have thousands tons stock of stainless steel sheet and coil with various size and grade,mainly include austenitic stainless steel, martens stainless steel (including precipitation hardened stainless steel sheet & coil), ferritic stainless steel, and duplex stainless steel.

Characteristics of Stainless Steel Sheet and Plate:

High corrosion resistance

High strength

High toughness and impact resistance

Temperature resistance

High workability, including machining, stamping, fabricating and welding

Smooth surface finish that can be easily clean