zero.1 mm metal sheet supplier

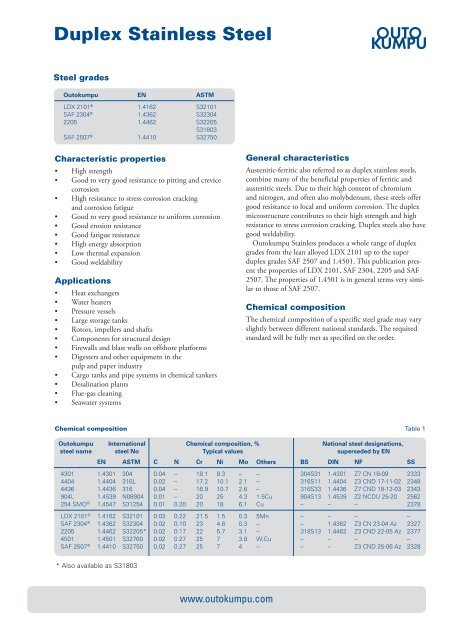

We produce ASTM/ASME Grade 304, Grade 304L,304h, 316, 316L, 316H, 316TI, 321, 321H, 309S, 309H, 310S, 310H, 410S, 2205, 904L, 2507, 254, gh3030, 625, 253MA, S30815, 317L, Type 317, 316lN, 8020, 800, 800H, C276, S32304 and others special requirement stainless steel grade.

The duplex microstructure contributes to the excessive strength and high resistance to emphasize corrosion cracking. Due to risk of embrittlement, LDX 2101 shouldn’t be used at temperatures above 250°C. The high chromium content of duplex stainless steels that protects against corrosion, causes embrittlement at temperatures over about 300°C.

En 1.4162 (X2crmnnin21-5- Stainless Steel

The vary of duplex steels allows them to be matched for corrosion resistance with the austenitic and ferritic steel grades. However, it is convenient to use the Pitting Resistance Equivalent Number (PREN) as a method of rating the grades. The idea of duplex stainless steels dates again to the 1920s with the primary cast being made at Avesta in Sweden in 1930. However, it’s only in the final 30 years that duplex steels have begun to “take off” in a major means. This is principally because of advances in steelmaking methods notably with respect to manage of nitrogen content material.

The allowable design values may differ between product varieties. The acceptable values are given in the relevant specs.

Technique

- A typical check temperature is minus 46 deg C for offshore oil and gas purposes.

- Minus eighty deg C is the lowest temperature that’s normally encountered for duplex steels.

- At the other end of the scale, there is a restriction on the low temperature use of duplex stainless steels in comparison with austenitic grades.

- Unlike austenitic steels duplex steels exhibit a ductile-brittle transition within the impact test.

Stock Thickness: 0.1-200.0mm

Production thickness: 0.5.0-200mm

Width: 600-3900mm

Length: 1000-12000mm

Grade:

200 series: 201,202

300 series: 301,304,304L,304H,309,309S,310S,316L,316Ti,321,321H,330

400 series: 409,409l,410,420J1,420J2,430,436,439,440A/B/C

Duplex: 329,2205,2507,904L,2304

Surface: No.1,1D,2D,2B,NO.4/4K/hairline,satin,6k,BA,mirror/8K

The metallurgy of duplex stainless steels is far more complicated than for austenitic or ferritic steels. This is why three day conferences could be devoted just to duplex! This factor implies that they’re harder to provide on the mill and to manufacture.

As a end result, LDX 2101 is priced competitively with 304L and 316L stainless-steel. Due to its comparatively low alloying content, it is less susceptible to precipitation of intermetallic phases than other duplex metal. The combination of a duplex construction and high nitrogen content present considerably higher energy levels than 316/316L stainless-steel.

Although machinable, the high strengths of duplex stainless steels makes machining tough. As an example, machining of 2205 is around 20% slower than for 304. It has a moderately low base value among wrought duplex stainless steels. In addition, it has a moderately low embodied vitality and a moderately high ductility.

Forta LDX 2101 is part of the Outokumpu Forta vary of stainless steels with excessive mechanical energy. If the excessive energy may be utilized, downgauging may be accomplished in lots of purposes, leading to cost-environment friendly solutions.

We have thousands tons stock of stainless steel sheet and coil with various size and grade,mainly include austenitic stainless steel, martens stainless steel (including precipitation hardened stainless steel sheet & coil), ferritic stainless steel, and duplex stainless steel.

Characteristics of Stainless Steel Sheet and Plate:

High corrosion resistance

High strength

High toughness and impact resistance

Temperature resistance

High workability, including machining, stamping, fabricating and welding

Smooth surface finish that can be easily clean