EN 10025-6 S620Q strength steel is

EN 10025-6 S620Q strength steel grade 8

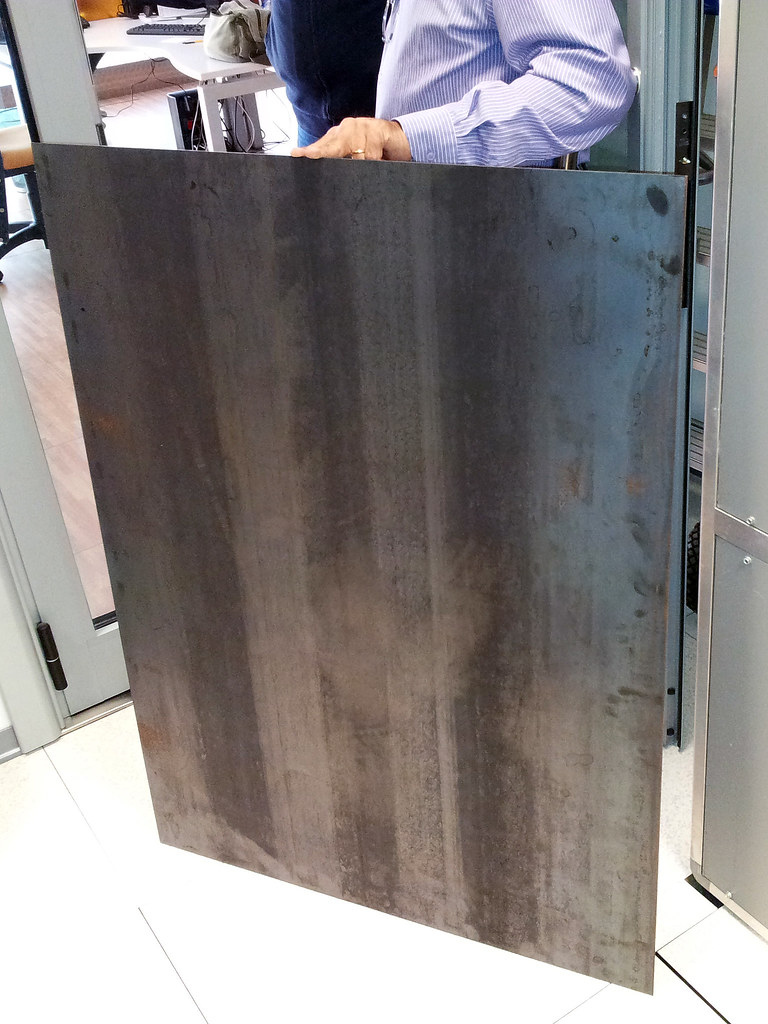

Gangsteel produce and supply materials of EN10025-6 S620q steel plate and equal grade S590Q, S690Q, S690QL, S690QL1, WQ690D, Q550D, WQ590D, WH70Q, WDB620E, WH785E S620q steel plate Executive standard: EN10025-6, GB/T16270-2009.

EN10025-6 S620q Alloy special steel with specified minimum values of impact energy at temperatures not lower than -20 degree .

Chemical composition of steel S620Q (1.8914), Standards of steel S620Q (1.8914) and Mechanical Properties of steel S620Q (1.8914) Equivalent grades of steel S620Q (1.8914)

about the steel S620Q (1.8914) Tensile Strength, Elongation, Proof strength , Hardness, please see our table.

EN 10025-6 S620Q strength steel in construction

API 5L X65 PSL1 Pipe is a high yield seamless pipe that is modified to suit offshore structural functions. It is meant for use in mounted offshore constructions and is designed to function within the offshore sector. 09CuPCrNi-A is a weather resistant metal created by alloying copper, chromium and nickel.

Equivalent supplies to the AISI 1025 carbon steel are given within the following desk. Carbon steels are steels containing only carbon as their key alloying element. These steels also have traces of 0.four% silicon and 1.2% manganese.

- What is EN 10025-6 S620Q steel plat?

EN10025-6 S620Q steel plate is EN 1.8914, Alloy special steel with specified minimum values of impact energy at temperatures not lower than -20 ° C. The main adopt standard are EN 10025-6: 2004 Hot rolled products of structural steels. Technical delivery conditions for flat products of high yield strength structural steels in the quenched and tempered condition

EN 10137-2: 1996 S620Q Plates and wide flats made of high yield strength structural steels in the quenched and tempered or precipitation hardened conditions. Delivery conditions for quenched and tempered steels

- What is EN 10025-6 S620Q OR 1.8914 Chemical composition % of steel EN 10025-6 S620Q (1.8914): EN 10025-6-2004

|

C |

Si |

Mn |

Ni |

P |

S |

Cr |

Mo |

V |

N |

Nb |

Ti |

Cu |

Zr |

B |

CEV |

|

max 0.2 |

max 0.8 |

max 1.7 |

max 2 |

max 0.025 |

max 0.015 |

max 1.5 |

max 0.7 |

max 0.12 |

max 0.015 |

max 0.06 |

max 0.05 |

max 0.5 |

max 0.15 |

max 0.005 |

max 0.83 |

- What is Mechanical properties of steel EN 10025-6 S620Q (1.8914)?

|

Nominal thickness (mm): |

3 – 100 |

100 – 150 |

|

Rm – Tensile strength (MPa) |

700-890 |

650-830 |

- What is Equivalent grades of steel EN10025-6 S620Q (1.8914)

|

EU |

Germany |

France |

European old |

|||

|

S620Q |

|

|

|

|

EN10025-6 EQUAL Grade stock list in China warehouse |

|||||||

|

|

Grade |

size mm |

Thick mm |

Wide mm |

Long mm |

Tons |

Quantity |

|

High-strength structural stee plate |

BS960E |

7*1600*11300 |

7 |

1600 |

11300 |

2.023 |

2 |

|

|

Q550CFD |

16*2500*12000 |

16 |

2500 |

12000 |

3.768 |

1 |

|

|

Q550CFD |

16*2500*12000 |

16 |

2500 |

12000 |

3.768 |

1 |

|

|

Q550CFD |

20*2500*12000 |

20 |

2500 |

12000 |

4.71 |

1 |

|

|

Q550CFD |

20*2500*12000 |

20 |

2500 |

12000 |

4.71 |

1 |

|

|

Q550CFD |

20*2500*12000 |

20 |

2500 |

12000 |

4.71 |

1 |

|

|

Q550CFD |

36*2500*9500 |

36 |

2500 |

9500 |

6.712 |

1 |

|

|

Q550CFD |

36*2500*9500 |

36 |

2500 |

9500 |

6.712 |

1 |

|

|

Q550CFD |

36*2500*9500 |

36 |

2500 |

9500 |

6.712 |

1 |

|

|

Q550CFD |

36*2500*9500 |

36 |

2500 |

9500 |

6.712 |

1 |

|

|

Q690CFD |

30*2550*10640 |

30 |

2550 |

10640 |

6.39 |

1 |

|

|

SC960E |

30*1550*5800 |

30 |

1550 |

5800 |

2.117 |

1 |

|

|

NQB-S690QL |

20*1700*11000 |

20 |

1700 |

11000 |

2.936 |

1 |

|

|

BS700MCK2 |

8*1500*13000 |

8 |

1500 |

13000 |

1.227 |

1 |

|

|

BWELDY620QL6 |

12*2400*6220 |

12 |

2400 |

6220 |

1.406 |

1 |

|

|

BWELDY620QL6 |

12*2400*9000 |

12 |

2400 |

9000 |

2.035 |

1 |

|

|

BS700MCK2 |

10*1500*4000 |

10 |

1500 |

4000 |

4.239 |

1 |

|

|

BS700MCK2 |

10*1500*4000 |

10 |

1500 |

4000 |

4.71 |

1 |

|

|

BS700MCK2 |

10*1500*4000 |

10 |

1500 |

4000 |

5.181 |

1 |

|

|

BS700MCK2 |

10*1500*4000 |

10 |

1500 |

4000 |

4.71 |

1 |

|

|

BS700MCK2 |

10*1500*4000 |

10 |

1500 |

4000 |

4.71 |

1 |

|

|

BS700MCK2 |

10*1500*4000 |

10 |

1500 |

4000 |

1.884 |

4 |

|

|

BS700MCK2 |

10*1500*6000 |

10 |

1500 |

6000 |

2.12 |

1 |

|

|

BS700MCK2 |

10*1500*6000 |

10 |

1500 |

6000 |

0.707 |

1 |

|

|

BS700MCK2 |

10*1500*6000 |

10 |

1500 |

6000 |

0.706 |

1 |

|

|

BS700MCK2 |

12*1500*12000 |

12 |

1500 |

12000 |

3.391 |

2 |

|

|

BS700MCK2 |

12*1500*12000 |

12 |

1500 |

12000 |

3.391 |

1 |

|

|

BS700MCK2 |

12*1500*12000 |

12 |

1500 |

12000 |

3.391 |

1 |

|

|

BS700MCK2 |

12*1500*13000 |

12 |

1500 |

13000 |

1.837 |

1 |

|

|

BS700MCK2 |

12*1500*4000 |

12 |

1500 |

4000 |

1.696 |

1 |

|

|

BS700MCK2 |

12*1500*4000 |

12 |

1500 |

4000 |

4.522 |

1 |

|

|

BS700MCK2 |

12*1500*4000 |

12 |

1500 |

4000 |

4.522 |

1 |

2. State: hot rolling, controlled rolling, normalizing, tempering, normalizing + tempering, quenching and tempering.

S355 structural grade carries minimal yield energy of 355 N/mm²m, the JR designation confirms that the link for you metal has undergone longitudinal Chary V-Notch impression testing at 27J at room temperature. ASTM A283 plate metal features low and intermediate tensile energy carbon steel plate of structural quality. Material Properties of S355 Steel An OverviewMaterial Properties of S355 Steel An Overview S355 is a non alloy European commonplace structural steel, most commonly used after S235 the place more power is required. It received great weldability and machinability, allow us to see more mechanical particulars of this steel.

See Details below for the outline of the related EN commonplace. We provide steel grade EN8 to some customers in center east like UAE, Europe international locations like UK and also in Africa like south africa. We will have some EN8 carbon metal promotion at the end of almost each month. Just ship emails with detailed requests for EN8 carbon steels price.

S355 is a non-alloy European standard (EN ) structural steel, most commonly used after S235 where more strength is needed. Satisfaction of shoppers is our primary goal, making an allowance for that we offer a quality accredited of plates, which are manufactured as per trade set constraints, underneath the management of our professional professionals. In addition, we manufacture these plates from supreme quality of raw materials, which is being mass-produced from real specialists of the market, in order to verify in providing a supreme quality product. All order process, high quality management, supply are in accordance with ISO9001, to ensure great quality for provided device steel or alloy steel supplies.

The following desk reveals the physical properties of the AISI 1025 carbon metal. See the place EN Grade S355JR normalized or normalized fashioned (+N) falls on the material property chart for Density in opposition to Elastic modulus in your materials selection and design course of. See the place EN Grade S620Q quenched and tempered (+QT) falls on the material property chart for Density towards Elastic modulus in your materials selection and design process. Normally S355 may have following variation based mostly on influence power at completely different temperatures, as metal turn out to be more brittle when temperature drops. If your construction need to face up to -20°C, it’s higher and safer to decide on S355J2. Preheat the EN8 steel rigorously, then raise temperature to 1050°C for forging. After forging cool en8 steel slowly, preferably in a furnace.

- After forging cool en8 steel slowly, ideally in a furnace.

- Normally S355 will have following variation based mostly on influence power at different temperatures, as steel turn into more brittle when temperature drops.

- See where EN Grade S620Q quenched and tempered (+QT) falls on the fabric property chart for Density in opposition to Elastic modulus in your supplies selection and design course of.

- If your construction want to face up to -20°C, it is better and safer to decide on S355J2.

- Preheat the EN8 metal fastidiously, then elevate temperature to 1050°C for forging.

We may supply EN8 steel in brilliant spherical bar in drawn/turned situation or spherical hot rolled, hexagon, sq., metal flats and plate. ASTM A333 Standard covers seamless and welded steel pipe for low temperature service. The Grade 6 metal concerned is just like AISI 4032 low alloy metal. ASTM A333 Grade 6 pipe shall be made by the seamless or welding course of with the addition of no filler metallic within the welding operation. of a fabric will increase when the temperature is raised by one degree is known as the coefficient of cubic enlargement. of a material will increase when the temperature is raised by one diploma known as the coefficient of superficial enlargement.

CTE stands for Coefficients of Thermal Expansion What is the abbreviation for Coefficients of Thermal Expansion? The hot rolled, unalloyed high quality steel S355JR is a better energy fine grained metal for steel structural engineering. Dimensioning advantages in respect to the S235JR due to the by a hundred and twenty MPa higher yield strength. The steel EN10025-6 S620Q steel plate supplier reveals a by 15% greater resistance to mineral put on due to sliding action in comparison to S235JR. Products within the supply situation +N may be sizzling fashioned and/or normalized after supply. For lengthy merchandise and continuous rolled flats the supply situation is as much as the producer +AR, +N or +M.

Small portions of copper, nickel, molybdenum, aluminium and chromium can be detected in the carbon steels. S355J2WP steel is a sizzling rolled structural metal with anti-corrosion characteristic, additionally called weathering steel and environment corrosion resistance metal, underneath commonplace EN . We join engineers, product designers and procurement groups with the best supplies and suppliers for their job.

Equivalent grades of steel S620Q (1.8914)Equivalent grades of steel S620Q (1.8914)Heat treatment conditions+A Soft annealed+AC Annealed to achieve spheroidization of the carbides+AR As rolled+AT Solution annealed+C Cold drawn / hard+CR Cold rolled+FP Treated to ferrite-pearlite structure and hardness range+I Isothermal annealing+LC Cold drawn / soft+M Thermo mechanical rolling+N Normalized+NT Normalized and tempered+P Precipitation hardened+PE Peeled+QA Air quenched and tempered+QL Liquid quenched and tempered+QT Quenched and tempered+S Treated to improve shearability+SH As rolled and turned+SR Cold drawn and stress relieved+T Tempered+TH Treated to hardness range+WW Warm worked+U Untreated

EN 10025-6 S620Q strength steel list

The following lists give PN 1.0117 PN EN properties such as physical properties, density, thermal growth. The chemical composition of the AISI 1025 carbon steel is printed in the following table. The following datasheet provides an overview of the AISI 1025 carbon steel. 16Mo3 Steel is a EN10028 specified strain vessel grade chrome molybdenum metal alloy is used as a weldable steel within the fabrication of industrial boilers and steel pressurised vessels discovered in the oil. List your organization on Matmatch now and attain engineers all over the world on the lookout for such supplies. Steel sub-grades JR, J0, J2, K2 characterize the ability of metal to behave in a ductile method and subsequently keep away from brittle fracture, particularly at low temperatures.