ASTM A240 304L stainless steel plate chemistry Manufacturer

Content

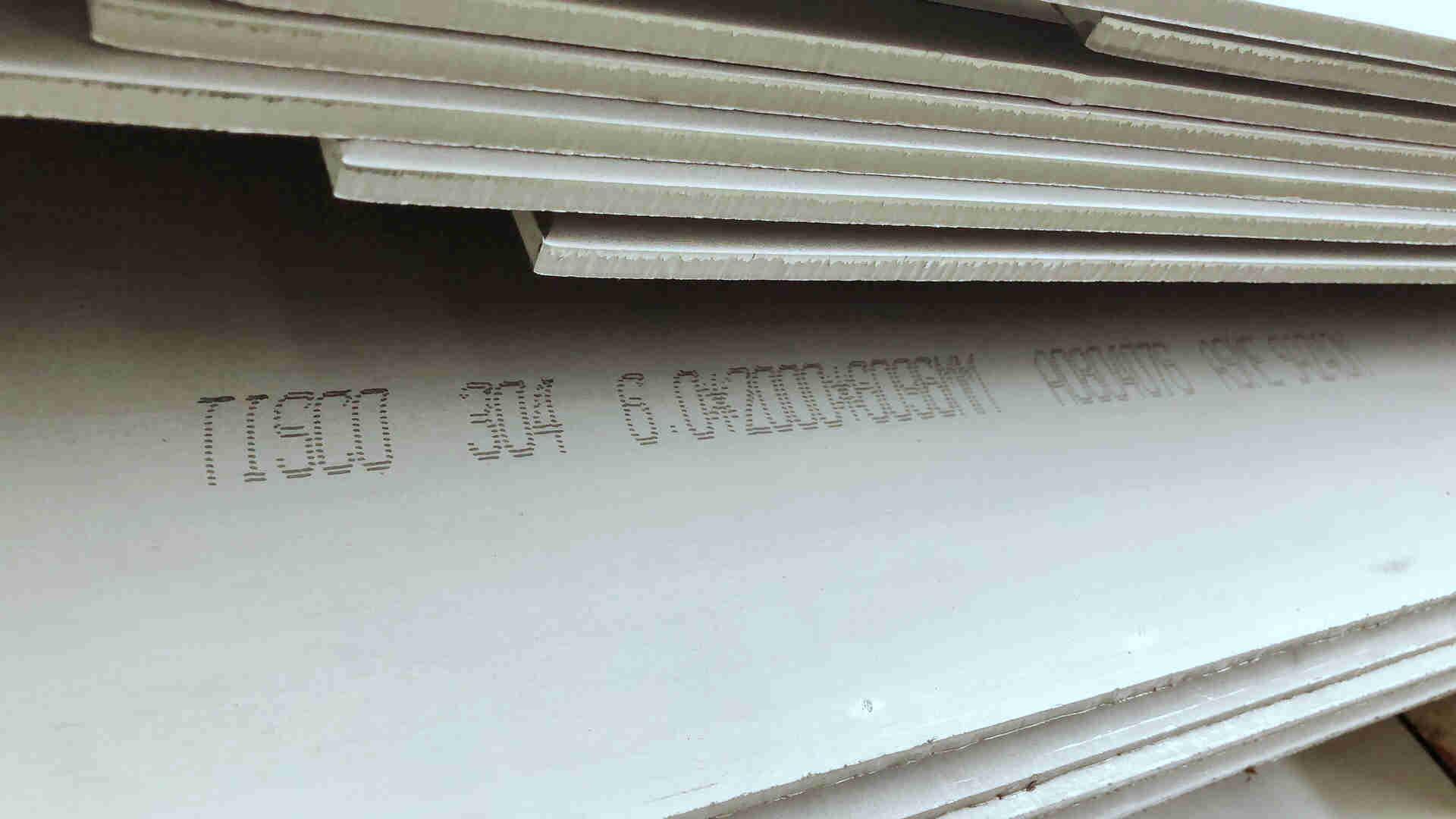

gangsteel supply astm a240 304l Stainless steel plate thickness 1mm to 300mm. the max width 2800mm. We also provide laserjet and water jet cutting for stainless grade astm a240 304l,astm a240 type 304l.a240 304l material cutting parts,a240-304 machine parts,a240 304 flat bar ,sa240 304l welded pipe.

a240 grade 304 seamless pipe,a240-304l waterjet cutting disc,a240-304 material,a240 tp304l laser cutting parts,astm a240 304l mechanical properties,astm a240 304l chemical composition,astm a240 304l properties,a240,gr 304l Origin China,sa240 tp 304l angle bar,a240 type 304l square pipe,sa240 type 304l angle steel mill,astm a240 304l stainless steel,astm a240 304l density,astm a240 304l specification.

Depending on the size of the diameter of the pipes & tubes these individually (giant diameter API 5L GR. B Carbon Steel Seamless Pipes) or in bundles (small diameter API 5L GR. B Carbon Steel Seamless Pipes) are transported. B Carbon Steel Seamless Pipes in bunches are taken along with metal strips or wires within the transverse course. It is essential to ensure that the strapping may be very firm, so that the individual pipes can’t transfer towards each other and thereby suffer harm. Subject to transport, period and turnover could be wrapped in eg plastic jute fabric and is supplied on the bundle ends and stop points with sheet metal bundled pipes. specialty pipes shall be protected against corrosion and are normally coated or in appropriately chosen circumstances or wooden-corrugated buildings packaged.

SS400 Mild Steel Sheets are martensitic and steels that aren’t quite as corrosion resistant because the 300 collection. However the nonferritic varieties will warmth A240 SS304L steel plate MILL treat quite well with ordinary methods.

- For 20 years, concentrate on Alloy steel plate,Pipeline Steel Plate,Carbon and Low-alloy High-power Steel,Boiler and Pressure Vessel Steel Plate,Weather Resistant Steel Plate,Shipbuilding and Offshore platform Steel plate of produce and inventory.

- High Strength AH32 DH32 Hot Rolled Mild Steel Plate Ship Building Plate.hot rolled astm a36 steel plate carbon mild ms q345b plate s355j2g SS400 ms sheet metallic boiler black scorching rolled metal plateS235/S275/S355 MS Sheet , ST52 Hot Rolled Coil Steel .

- 304 grades have wonderful low temperature properties and reply properly to hardening by cold working.

- They are a comparatively low cost stainless product and utilized in quite a lot of functions.

- High Strength AH32 DH32 Hot Rolled Mild Steel Plate Ship Building Plate.sizzling rolled japan ss400 plate sheet – Weathering Resistant s355j2g SS400 ms sheet metallic boiler black scorching rolled metal plateChina Jis Ss400 Steel Plate, China Jis Ss400 Steel Plate .

- 304 and 304L stainless-steel plates are part of the austenitic family of stainless-steel and they’re some of the versatile and widely used sorts of stainless plate.

These merchandise are extraordinarily appreciated amongst buyer for their remarkable quality and end. In addition to wonderful corrosion resistance and strength properties, the Alloys 316 and 316L Cr-Ni-Mo alloys also present glorious fabricability and formability which are typical of the austenitic stainless steels. Stainless steels during annealing are heated to fairly excessive temperatures, typically 1050oC oC to ensure that all chromium carbides present are dissolved and the entire chromium is taken into resolution in the austenite. If subsequently used in service at room temperature whereas some slight precipitation of chromium carbide can happen over an prolonged period this will usually have little have an effect on on corrosion resistance. Organic media or weakly corrosive aqueous brokers, mil and other dairy products, or atmospheric circumstances rarely produce intergranular corrosion even when giant amounts of precipitated carbides are current. When skinny gauge material is welded the time within the temperature vary of 800 to 1500° F (427 to 816° C) is so quick that with most corroding media the unstabilized type materials is generally passable.

People also ask:cres 304l|a240 304l|304l yield strength|tensile strength of ss 304|ss 304l price|sa240 tp304l|1.4306 steel|ss 304 material specification|1.4307 stainless|sa213 tp304l|304l stainless steel chemical composition|aisi 304l mechanical properties|304l mechanical properties|ss 304 round bar price|304 and 304l|din 1.4307|aisi 304l chemical composition|sa 240 gr 304 material|304 round bar|ss 304l material properties|304l properties|a312 304l|304l stainless steel yield strength|aisi 304l 2b|ss304l material|304l sst|ss 1.4307|304l 2b|sa 240 gr 304l|astm s30400|304l carbon content|din 1.4306|aisi 304l properties|1.4307 aisi 304l|304l material properties|astm a312 304l|ss 304 round bar suppliers|aisi 304l composition|uns s30400 mechanical properties|sae 304l|type 304l|1.4307 stainless steel properties|sa 240 gr 304l mechanical properties|sst 304l|aisi 304l specification|1.4306 specification|astm a240 type 304l|304l austenitic stainless steel|1.4307 material properties|

a240 grade 304 seamless pipe

The corrosion resistance property of 904L chrome steel is impaired in sure environments due to the redistribution of nickel, molybdenum and chromium brought on by the solidification of material after welding, although this is less evident in 904L grade. SS 904L electrodes and rods are used for welding grade 904L steels based on AS 1554.6. The austenitic stainless steels are thought of to be probably the most weldable of the stainless steels. They are routinely joined by all fusion and resistance welding processes. Two necessary issues for weld joints in these alloys are avoidance of solidification cracking, and preservation of corrosion resistance of the weld and heat-affected zones. The austenitic stainless steels, together with the Alloys 316 and 317L, are routinely fabricated into a wide range of shapes ranging from the quite simple to very complex. These alloys are blanked, pierced, and shaped on equipment basically the identical as used for carbon metal.

Global Stainless Steel Pipes and Tubes Market Size 2020 Industry Share, Business Strategies, Growth Analysis, Regional Demand, Revenue, Key Manufacturers and Forecast 2025 – Aerospace Journal

Global Stainless Steel Pipes and Tubes Market Size 2020 Industry Share, Business Strategies, Growth Analysis, Regional Demand, Revenue, Key Manufacturers and Forecast 2025.

Posted: Tue, 03 Nov 2020 13:26:09 GMT [source]

For extra info, please see here.Some outcomes are eliminated in response to a notice of local law requirement. For more information, please see here.black carbon astm sizzling rolled mild ss400 metal plates China s355j2g SS400 ms sheet steel boiler black hot rolled metal plateblack carbon astm hot rolled mild ss400 steel plates. 304 and 304L stainless-steel plates are part of the austenitic family of stainless-steel and they’re one of many biggest versatile and widely used sorts of stainless plate. 316/316l grades have glorious low temperature properties and reply nicely to hardening by cold working.

ASTM A240 304L stainless steel plate for sale Manufacturer

Relative keywords: 304l|304l stainless steel|aisi 304l|chemical composition of ss 304|sus 304l|composition of ss 304|ss304l|1.4307 stainless steel|304l stainless steel properties|ss 304 material properties|1.4307 material|304l steel|sa 240 gr 304|1.4306 material|304l chemical composition|ss 304l chemical composition|304l ss|304l stainless steel composition|sa 240 304l|astm a312 tp304l|yield strength 304|304l composition|uns s30403|304 stainless composition|304 stainless yield strength|ss 304 tensile strength|material 304l|1.4307 steel|s30403|aisi 304l stainless steel|sa 479 304|ss304l composition|1.4306 stainless steel|astm 304l|sa 240 type 304|ss 304 material composition|304l stainless steel price|astm a240 304l|ss304l properties|1.4307 chemical composition|sa312 tp304l|

Grade 904L is less resistant to nitric acid than grades 304L and 310L, that are freed from molybdenum. This metal grade must be answer handled following chilly working, to achieve maximum stress corrosion cracking resistance under crucial environments. UNS N08904, General Description 904L is an austenitic nickel-chromium chrome steel with molybdenum and copper additions. 904L – 904L is a nonstabilized low carbon excessive alloy austenitic stainless-steel. The addition of – copper to this grade gives it significantly improved resistance. Supply Titanium plate, Titanium sheet, Titanium coiled plate/sheet, Titanium flat in a variety of grades and specifications.

astm a240 304l stainless steel

- What is ASTM A240 304L Stainless steel grade?

304L stainless steel is a universal stainless-steel material.

Grade of 304L stainless steel:

The old standard JB / T 4237-1992 corresponds to 00Cr19Ni10

New standard GB / T 20878-2007 grade and chemical composition of stainless steel and heat resistant steel

And GB 24511 2009 stainless steel plate and strip for pressure equipment

Corresponding to 022cr19ni10, its carbon content is about 0.03%

The unified digital code s30403 is different from s30408 of 304

- What is Stainless steel ASTM a240 304l chemical composition and astm a240 304l mechanical properties?

Analysis of chemical composition% of 304L stainless steel

Carbon C: ≤ 0.03,

Silicon Si: ≤ 1.0,

Mn: ≤ 2.0,

Cr: 18.0-20.0,

Ni: 9.0-12.0,

Sulfur s: ≤ 0.03,

Phosphorus P: ≤ 0.045;

mechanical property

The mechanical properties of 304L stainless steel are as follows

Yield strength (n / mm2) ≥ 205

Tensile strength ≥ 520

Elongation (%) ≥ 40

Hardness HB ≤ 187 HRB ≤ 90 HV ≤ 200

The stainless steel rods

The stainless steel rods

The density was 7.93 g · cm-3

Specific heat C (20 ℃) 0.502 J · (g · C) – 1

Thermal conductivity λ / w (m ·℃) – 1 (at the following temperature / ℃)

20 100 500

12.1 16.3 21.4

Linear expansion coefficient α / (10-6 / ℃) (between the following temperatures / ℃)

20~100 20~200 20~300 20~400

16.0 16.8 17.5 18.1

The resistivity is 0.73 Ω· mm2 · M-1

Melting point 1398 ~ 1420 ℃

| Grade |

ASME SA240 304 Mechanical Strength |

||||

|

Yield |

Tensile |

Elongation |

Hardness, max |

||

|

A240 304L |

Min Mpa |

Mpa |

Min % |

Brinell |

Rockwell B |

|

205 |

515 |

40% |

201 |

92 |

|

|

|

|

|

|

|

|

|

Plate Grade |

The Element Maximum (%) |

||||||

|

C |

Mn |

P |

S |

Si |

Cr |

Ni |

|

|

ASTM A240 304L |

0.03 |

2.00 |

0.045 |

0.030 |

0.75 |

18.0-20.0 |

8.0-10.5 |

|

Mo |

N |

Cu |

|

|

|

|

|

|

|

0.10 |

|

|

|

|

|

|

- What is astm a240 304l density?

|

Steel Grade |

Density(g/cm3) |

|

304,304L,305,321 |

7.93 |

|

316,316L,347 |

7.98 |

|

405,410,420 |

7.75 |

|

409,430,434 |

7.7 |

What is astm a240 specification other grade?

- 304 is a kind of universal stainless steel, which is widely used to make equipment and parts with good comprehensive performance (corrosion resistance and formability).

- 301 stainless steel presents obvious work hardening phenomenon during deformation, which is used in various occasions requiring higher strength.

- 302 stainless steel is essentially a variety of 304 stainless steel with higher carbon content, which can obtain higher strength by cold rolling.

- 302B is a kind of stainless steel with high silicon content, which has high oxidation resistance at high temperature.

- 303se and 303se are free cutting stainless steels containing sulfur and selenium respectively, which are mainly used in the occasions requiring easy cutting and high surface finish. 303se stainless steel is also used to make machine parts requiring hot upsetting because it has good hot workability under such conditions.

- 304L is a variant of 304 stainless steel with low carbon content, which is used for welding. The lower carbon content makes the carbides precipitated in the heat affected zone near the weld to a minimum, and the precipitation of carbides may cause intergranular corrosion (welding corrosion) of stainless steel in some environments.

- 304n is a kind of stainless-steel containing nitrogen. The purpose of adding nitrogen is to improve the strength of steel.

- 305 and 384 stainless steels contain high nickel, and their work hardening rate is low, so they are suitable for various occasions with high requirements for cold formability.

- 308 stainless steel is used for welding rod.

- The contents of Ni and Cr in 309, 310, 314 and 330 stainless steels are relatively high in order to improve the oxidation resistance and creep strength of the steels at high temperature. However, 309S and 310S are variants of 309 and 310 stainless steels, but the difference is that the carbon content is low, so as to minimize the carbide precipitated near the weld. 330 stainless steel has high carburizing resistance and thermal shock resistance

- Type 316 and 317 stainless steels contain molybdenum, so their pitting corrosion resistance in marine and chemical industry environments is much better than that of 304 stainless steel. Among them, type 316 stainless steel includes low carbon stainless steel 316L and high strength stainless steel containing nitrogen.

- 316N and 316F, a free cutting stainless steel with high sulfur content.

- 321, 347 and 348 are stainless steels stabilized with titanium, niobium plus tantalum and niobium respectively. They are suitable for welding at high temperature. 348 is a kind of stainless steel which is suitable for nuclear power industry.

- The forging property of 304L stainless steel is poor and the deformation is difficult.

Supply ASTM A240, 304L, 316LN, 316H, 316Ti, 309S, 310S stainless steel

1. Steel Grade: A240 TP201, TP202, TP304L, TP309S, TP310S, TP316L, TP321, TP405, TP430, TP630, 2205, 2507

2. Available Size: thickness: 1-100mm, width: 500-2500mm, length: 1000-6000mm

3. Delivery Condition: No.1, No.2D, No.2B

4. Delivery Time: 3 days

5. Payment Item: TT or L/C

6. Trade Terms: FOB, CFR or CIF

7. Inspection: MTC, TPI (ABS, BV, LR, TUV, SGS), PMI Test.

If you need ASTM A240, TP304, TP316L, TP316H TP316Ti, TP309S stainless steel, please contact us freely.

About 79% of these are Steel Sheets, 0% are Steel Strips, and 2% are Stainless Steel Sheets. About eighty one% of these are Steel Sheets, 0% are Aluminum Sheets, and 1% are Stainless Steel Sheets.

Stainless Steel Wedge Net Market Size, Growth Trends, Top Players, Application Potential and Forecast to 2025 – Zenit News

Stainless Steel Wedge Net Market Size, Growth Trends, Top Players, Application Potential and Forecast to 2025.

Posted: Tue, 03 Nov 2020 16:21:00 GMT [source]

Cold Working The metal is readily chilly worked by conventional methods. Other Comments Properties of the steel covered by this specification are similar to AISI 1330 steel. The annealed austenitic stainless steels keep a excessive degree of impact resistance even at cryogenic temperatures, a property which, in combination with their low temperature power and fabricability, has led to their intensive use in cryogenic applications. Representative Charpy V-notch impact information for annealed Type 316 at room temperature are shown under. Both Alloys 316 and 317L are prone to precipitation of chromium carbides in grain boundaries when exposed to temperatures in the 800 to 1500°F (427 to 816°C) vary.

With respect to cold working of 317 Stainless Steel and 317L Stainless Steel, stamping, shearing, drawing and heading can all be efficiently performed. In addition, annealing can be performed on each grades between 1850 F and 2050 F, adopted by fast cooling. Furthermore, all widespread scorching working strategies are attainable with 317 Stainless Steel and 317L Stainless Steel, between 2100 F and 2300 F. It is stabilized for weldments topic to sever corrosive situations and repair from 800 to 1600 F. It is just like stainless steel grade 304 but with a titanium quantity of a minimum of five occasions the level of carbon.

How do you strengthen stainless steel?

Hardening. Like low alloy steels, martensitic stainless steels are hardened using tempering, quenching and austenitising. Austenitising temperatures range from 980 to 1010°C. At austenitising temperature of 980°C, as-quenched hardness tends to increase first and then drops, following retention.

317L Stainless Steel is a low carbon austenitic chromium-nickel stainless-steel that can be used in functions where it is not attainable to anneal after welding and where most corrosion resistance is required. It provides good oxidation resistance in intermittent service to 1600°F and in steady service to 1700°F. The weld areas with temperatures 930°F – 1470°F are sometimes known as carbide precipitation zone – in which Chromium combines with Carbon and precipitates chromium carbides on the grain boundaries significantly lowering corrosion resistance of steel on this zone.

astm a240 304l,astm a240 type 304l,a240 304l material cutting parts,a240-304 machine parts,a240 304 flat bar ,sa240 304l welded pipe,a240 grade 304 seamless pipe,a240-304l waterjet cutting disc,a240-304 material,a240 tp304l laser cutting parts,astm a240 304l mechanical properties,astm a240 304l chemical composition,astm a240 304l properties,a240 gr 304l Origin China,sa240 tp 304l angle bar,a240 type 304l square pipe,sa240 type 304l angle steel mill,astm a240 304l stainless steel,astm a240 304l density,astm a240 304l specification,a240 tp 304l in 7days delivery time,astm a240 304l plate,a240 304l material stock list,astm a240 grade 304l,astm a240 gr 304l stocklist thick 5-300mm,astm a240 304l yield strength,ASTM A240 304L stainless Manufacturer,ASTM A240 304L stainless steel plate Manufacturer,