Aisi 1005

We produce ASTM/ASME Grade 304, Grade 304L,304h, 316, 316L, 316H, 316TI, 321, 321H, 309S, 309H, 310S, 310H, 410S, 2205, 904L, 2507, 254, gh3030, 625, 253MA, S30815, 317L, Type 317, 316lN, 8020, 800, 800H, C276, S32304 and others special requirement stainless steel grade.

It has a fairly high thermal conductivity among wrought carbon or non-alloy steels. In addition, it has a fairly low electrical conductivity and a very low tensile strength. SAE-AISI 1005 steel is a carbon (non-alloy) steel formulated for main forming into wrought merchandise. Cited properties are applicable for the chilly labored (strain hardened) condition.

Three cutting parameters i.e. spindle speed (N), depth of cut (dc) and feed price (f) had been optimized with consideration of floor roughness (Ra) and material removing fee (MRR). Experiments have been carried out based on L9 orthogonal array. Effect of chopping parameter were analyzed utilizing ANOVA and the results shows that the depth of minimize and feed rate influences the responses the most. Furthermore, affirmation experimental take a look at has been performed primarily based on optimal parameter to justify the outcomes.

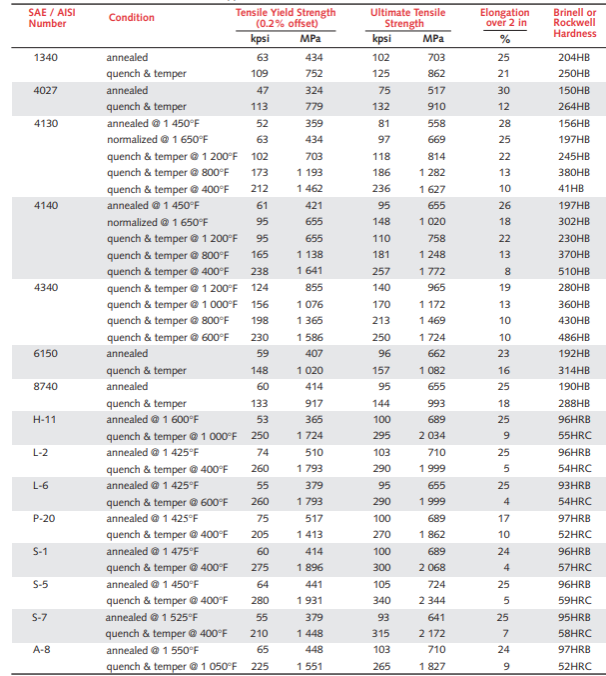

The typical tensile strength varies between 276 and 1882 MPa. The big selection of ultimate tensile energy is essentially because of different heat therapy circumstances. This web page offers AISI 1005 datasheet, AISI 1005 mechanical properties, chemical factor AISI 1005, technical specs of AISI 1005 steel material properties. The bodily properties of the AISI 1005 carbon metal are tabulated under. These Carbon Steel UNS G10050 Forging are accessible in a scope of determinations for caring for the fluctuated requests of assorted utility zones.

Technique For our stainless

Our stainless production range

- It consists of (in weight share) zero.06%(max) Carbon (C), zero.35%(max) Manganese (Mn), zero.04%(max) Phosphorus (P), zero.05%(max) Sulfur (S), and the base steel Iron (Fe).

- Other designations of AISI 1005 carbon steel embody UNS G10050 and AISI 1005.

- The thermal properties of the AISI 1005 carbon steel are given within the following table.

Aisi 1005 Characteristics

It consists of (in weight percentage) zero.06%(max) Carbon (C), zero.35%(max) Manganese (Mn), zero.04%(max) Phosphorus (P), zero.05%(max) Sulfur (S), and the base steel Iron (Fe). Other designations of AISI 1005 carbon steel embrace UNS G10050 and AISI 1005. The thermal properties of the AISI 1005 carbon metal are given within the following desk. The following desk shows mechanical properties of the AISI 1005 carbon steel.

All our Carbon Steel 1005 Forged Products may be obtainable with Black & Bright Surface in addition to Finished surfaces. All these merchandise can be found with Relevent Mill Test Certificates, Heat treatment along with UT testing or NDT testing as required by the shoppers. We supply a wide range of Carbon Steel 1005 Custom Shape Forgings to our esteemed clients as per the national and worldwide requirements. They can further be custom-made in terms of sizes and thicknesses as per specific requirements and are offered the same in market main prices.

1005 is the designation in both the SAE and AISI methods for this materials. The following datasheet will talk about in regards to the AISI 1005 carbon metal. Taguchi approach was employed to seek out out the optimum slicing parameters in face milling operation of AISI 1005 metal utilizing TiN coated software.

Carbon Steel

The chemical composition of the AISI 1005 carbon metal is outlined within the following desk. The typical elastic modulus of carbon steels at room temperature (25°C) ranges from a hundred ninety to 210 GPa. The typical density of carbon steels is about 7.85 g/cm3.

We have thousands tons stock of stainless steel sheet and coil with various size and grade,mainly include austenitic stainless steel, martens stainless steel (including precipitation hardened stainless steel sheet & coil), ferritic stainless steel, and duplex stainless steel.

Characteristics of Stainless Steel Sheet and Plate:

High corrosion resistance

High strength

High toughness and impact resistance

Temperature resistance

High workability, including machining, stamping, fabricating and welding

Smooth surface finish that can be easily clean