Aisi 660 Datasheet, Aisi 660 Property, Aisi 660 Standard Specification, Aisi 660 Standard Download

We produce ASTM/ASME Grade 304, Grade 304L,304h, 316, 316L, 316H, 316TI, 321, 321H, 309S, 309H, 310S, 310H, 410S, 2205, 904L, 2507, 254, gh3030, 625, 253MA, S30815, 317L, Type 317, 316lN, 8020, 800, 800H, C276, S32304 and others special requirement stainless steel grade.

The following desk is for reference solely, many elements can affect the corrosive resistance, a corrosion test for every software ought to be applied. Lorem Ipsum is just dummy textual content of the printing and typesetting trade. Lorem Ipsum has been the industry’s normal dummy text ever because the 1500s, when an unknown printer took a galley of sort and scrambled it to make a kind specimen book.

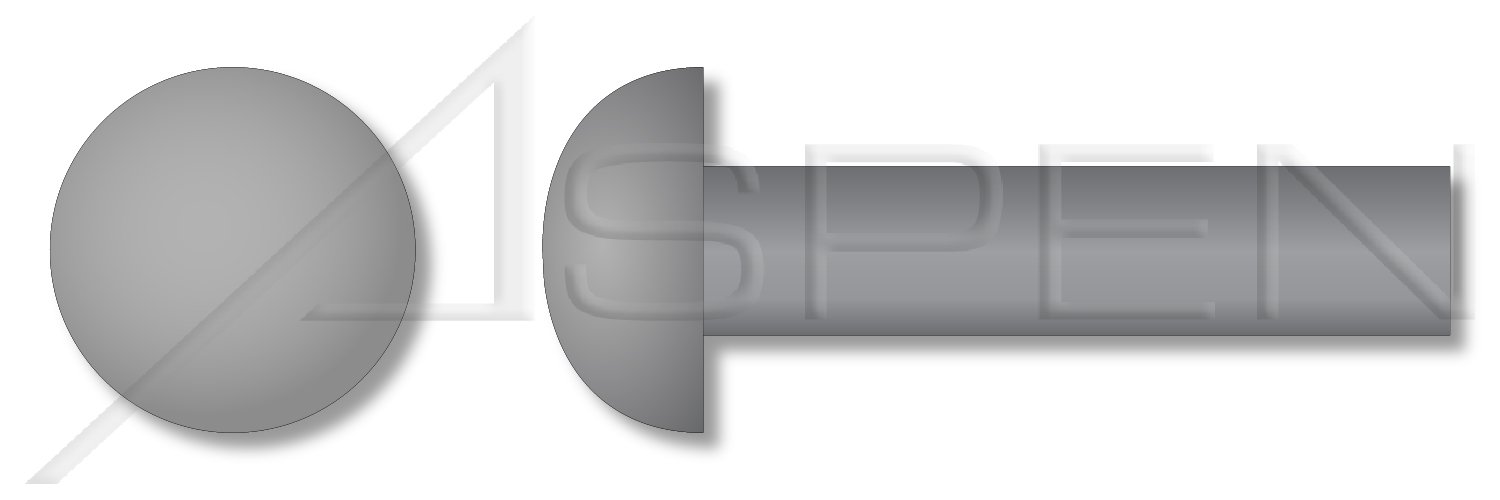

Long, gummy chips characterize this alloys machinability. It could be machined within the annealed condition, nevertheless situation H1150M will yield finest results. Post machining resolution treatment of components shall be required previous to final hardening if machining on this condition. AISI 660 can be supplied as steel plate/ sheet, spherical metal bar, steel tube/pipe, metal stripe, steel billet, steel ingot, steel wire rods. As with austenitic stainless-steel hardening of this alloy is completed bycold working.

A286 Stainless Steel Specifications:

While soft and ductile in the solution annealed condition, it’s able to high properties with a single precipitation or growing older treatment. Characterized by good corrosion resistance, high harness, toughness and energy. This page offers AISI 660 datasheet, AISI 660 mechanical properties, chemical factor AISI 660, technical specifications of AISI 660 steel material properties. As with all nickel containing alloy cleanliness of the area to beweldedis of paramount importance. Welding procedures and processes are the same as used for stainless-steel.

- Alloy 660 Round Bars offers excessive ductility in notched sections and is superior to many other commercial alloys with comparable high temperature properties.

- Alloy 660 Round Bars is can be utilized in a wide range of high temperature purposes, fasteners, generators, important frames in excessive stress/warmth purposes, castings and fasteners.

- These Alloy UNS S66286 Round Bars is an iron-based tremendous-alloy useful for functions requiring high energy and corrosion resistance up to 1300 Degree F (704 Degree C) and for lower stress functions at greater temperatures.

- Leoscor Alloys is a known producer and supplier of Alloy 660 Round Bars, which is an iron-primarily based excessive temperature and high power alloy.

Delivery time��7 to 15 days, depends on the quantity

Stock Thickness: 0.1-200.0mm

Production thickness: 0.5.0-200mm

Width: 600-3900mm

Length: 1000-12000mm

Grade:

200 series: 201,202

300 series: 301,304,304L,304H,309,309S,310S,316L,316Ti,321,321H,330

400 series: 409,409l,410,420J1,420J2,430,436,439,440A/B/C

Duplex: 329,2205,2507,904L,2304

Surface: No.1,1D,2D,2B,NO.4/4K/hairline,satin,6k,BA,mirror/8K

Type A286 alloy is on the market in plate, sheet and strip. Manufacturer of Stainless Steel Tube, Stainless Steel Pipe, SS Pipe, Stainless Steel Tubing, Nickel Alloy Tubing in China. LSS™ A286 is available in a variety of ingot, billet, bar, and coil rod sizes. A286 alloy offers excessive strength as much as a temperature of 1300° F andcorrosion resistanceup to a constant temperature of 1500° F or an intermittenttemperatureof 1800° F. A286, which is a ductile, non-magnetic, iron-primarily based alloy, can reach its highest strength level through solutionheat treatingand age hardening.

AISI 660 Round Bars has excessive mechanical properties as a result of age-hardenability and has high ductility in notched sections. Alloy 660 Round Bars is can be used in a wide range of excessive temperature applications, fasteners, turbines, critical frames in high stress/warmth applications, castings and fasteners. Meanwhile, Heavy forging and light forging are suitable for SUH 660 Round Bars.

Preheating or publish weldingheat treatmentis not required. Welds ought to at all times have a raised (convex) weld bead and matching filler steel ought to be used.

The alloy must be in the resolution annealed condition for optimum welding outcomes. It is vulnerable to scorching cracking and that tendency is aggravated within the aged situation. Continental Steel is proud to be a distributor of Alloy 660 in a spread of styles and sizes together with coil, sheet, and plate. The Alloy 600 metals that we supply, meets NAS, UNS, JIS, and ASTM (A453, A638) specs and requirements. One thing to notice about Alloy 600’s chemical composition is that as a result of its excessive nickel content material for a chrome steel, it usually categorized as a nickel alloy, thus the A-286 label.

We have thousands tons stock of stainless steel sheet and coil with various size and grade,mainly include austenitic stainless steel, martens stainless steel (including precipitation hardened stainless steel sheet & coil), ferritic stainless steel, and duplex stainless steel.

Characteristics of Stainless Steel Sheet and Plate:

High corrosion resistance

High strength

High toughness and impact resistance

Temperature resistance

High workability, including machining, stamping, fabricating and welding

Smooth surface finish that can be easily clean