How Is Stainless Steel Made?

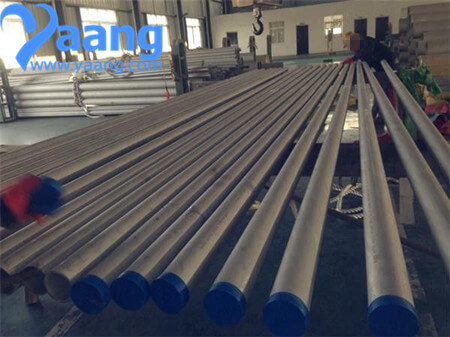

We produce ASTM/ASME Grade 304, Grade 304L,304h, 316, 316L, 316H, 316TI, 321, 321H, 309S, 309H, 310S, 310H, 410S, 2205, 904L, 2507, 254, gh3030, 625, 253MA, S30815, 317L, Type 317, 316lN, 8020, 800, 800H, C276, S32304 and others special requirement stainless steel grade.

It is readily brake or roll formed into a wide range of parts for purposes in the industrial, architectural, and transportation fields. Grade 316 additionally has outstanding welding traits.

This kind of chrome steel is often used in the warmth exchangers, oil and gas industry, chemical processing gear, offshore platforms, stress vessels, and boilers. It combines the most effective attributes of ferritic and austenitic stainless steel and presents excellent energy as well as ductility with excessive corrosion resistance. Average Welded Pipe and seamless steel pipe the chemical composition has a sure distinction. The manufacturing of seamless steel element is just astm the basic requirements. Produce seamless metal pipe steel with the chemical composition suitable for welding.

All these properties and features make duplex chrome steel the favored choice for various pressure vessels and structural purposes. covers seamless and straight-seam welded ferritic/austenitic steel pipe supposed for general corrosive service, with explicit emphasis on resistance to stress corrosion cracking. These steels are prone to embrittlement if used for prolonged durations at elevated temperatures.

Length: 2000mm, 2438mm,2500mm,3000mm,6000mm,or required

- Tension tests, hardening tests, flattening exams, hydrostatic test and nondestructive electric tests shall be made to conform to the desired requirements.

- Heat evaluation shall be made to determine the percentages of the weather specified.

- ASTM A790 covers seamless and straight-seam welded ferritic/austenitic duplex chrome steel pipe for basic corrosive service, with particular emphasis on resistance to emphasize corrosion cracking.

- The pipe shall be made by the seamless or an automated welding course of, with no addition of filler metal in the welding operation.

- Our company is an worldwide provider of stainless-steel seamless and welded pipe.

Stock Thickness: 0.1-200.0mm

Production thickness: 0.5.0-200mm

Width: 600-3900mm

Length: 1000-12000mm

Grade:

200 series: 201,202

300 series: 301,304,304L,304H,309,309S,310S,316L,316Ti,321,321H,330

400 series: 409,409l,410,420J1,420J2,430,436,439,440A/B/C

Duplex: 329,2205,2507,904L,2304

Surface: No.1,1D,2D,2B,NO.4/4K/hairline,satin,6k,BA,mirror/8K

ASME requirements 100% by ultrasonic test pipe joints can be fully exposed to the license pressure. Similarly, Europe and Asia also offers through the eddy current test pipe joints to ensure the efficiency of the welding high quality, eddy current testing require the approval of the authorized procedures and permit establishments. The trent eddy present testing by the permission of the Swedish Ministry of Energy.

What Is Duplex Steel?

The tube should be annealed at 2100°F minimal after scorching working and cooled quickly, ideally by water quenching. This anneal is critical to get rid of intermetallic phases probably precipitated during sizzling working, and thus present most corrosion resistance. The specification covers seamless and straight-seam welded ferritic/austenitic metal pipe for common corrosive service, with explicit emphasis on resistance to stress corrosion cracking. Tension tests, hardening checks, flattening exams, hydrostatic exams and nondestructive electrical exams shall be made to evolve to the required necessities.

It is taken into account twice as sturdy as the other metals. Because of its increased strength, the thinner sections could be simply created that in flip provide significant weight financial savings.

But generally by the market pressure, welded pipe is costlier, so if you met this case, don’t hesitate to buy the seamless steel pipe for a similar dimensions. the energy of the pipe is determined by the alloy composition, which contains the identical alloy and the same heat therapy of seamless and seamed pipe energy are the same in essence. After tensile take a look at and three-dimensional vibration take a look at, tear Welded Pipe happens nearly exclusively in a spot away from the welding level or heated areas. This is because the weld impurities less and the nitrogen content material is greater, and thus the strength of the weld is best in different elements. ASME Boiler and Pressure Vessel Association, nevertheless, that a slit pipe can solely afford 85% of the license stress, which is principally due to the collection of data as early as welding equipment in use at present have improved.

We have thousands tons stock of stainless steel sheet and coil with various size and grade,mainly include austenitic stainless steel, martens stainless steel (including precipitation hardened stainless steel sheet & coil), ferritic stainless steel, and duplex stainless steel.

Characteristics of Stainless Steel Sheet and Plate:

High corrosion resistance

High strength

High toughness and impact resistance

Temperature resistance

High workability, including machining, stamping, fabricating and welding

Smooth surface finish that can be easily clean