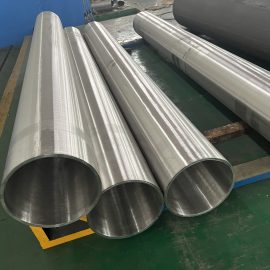

Seamless Pipe

We produce ASTM/ASME Grade 304, Grade 304L,304h, 316, 316L, 316H, 316TI, 321, 321H, 309S, 309H, 310S, 310H, 410S, 2205, 904L, 2507, 254, gh3030, 625, 253MA, S30815, 317L, Type 317, 316lN, 8020, 800, 800H, C276, S32304 and others special requirement stainless steel grade.

Menu Pipes

These seamless pipes are highly resistance to chloride corrosion and subsequently the316l Stainless Steel Piperesistant to pitting and crevice corrosion even underneath chloride rich environments. Our Stainless Steel Pipe 316l Seamless products can be utilized in boats, marine functions, sea water purification methods and in waste water management applications as properly. There are totally different schedules of the pipes to accommodate completely different diameters and wall thicknesses. The Stainless Steel Pipe 316l Schedule forty is a medium vary pressure containment capacity whereas the Stainless Steel Pipe 316l Schedule 10s has comparatively smaller wall thickness. Our 316l Seamless Pipe Schedule 40 Pipe are some of the used within the oil & gas industries.

Our Stainless Steel Pipe A312 Tp316l ranges from small to medium sizes. We also can produce customASTM A312 Tp316l Seamlesspipes as properly. The stainless-steel pipes are one of the most used products within the piping applications.

1.5 Grades TP321 and TP321H have decrease strength requirements for pipe manufactured by the seamless process in nominal wall thicknesses greater than three/8 in. 1.1 This specification covers seamless and straight-seam welded austenitic metal pipe supposed for high-temperature and general corrosive service. Standard specification for nickel-chromium-iron alloys (UNS N06600, N06601, N06603, N06690, N06693, N06025, and N06045) and nickel-chromium-cobalt-molybdenum alloy (UNS N06617) seamless pipe and tube. Therefore, duplex pipes combine the qualities of ferritic and austenitic chrome steel supplies. The time period “duplex” refers to a household of stainless steels which have double construction – i.e. they’re neither a completely austenitic SS structure, like 304 stainless, nor a normal ferritic, such because the 430 collection.

- The Stainless Steel Pipe 316l Schedule forty is a medium vary stress containment capability whereas the Stainless Steel Pipe 316l Schedule 10s has comparatively smaller wall thickness.

- These seamless pipes are highly resistance to chloride corrosion and due to this fact the316l Stainless Steel Piperesistant to pitting and crevice corrosion even under chloride wealthy environments.

- There are completely different schedules of the pipes to accommodate totally different diameters and wall thicknesses.

- Our 316l Seamless Pipe Schedule forty Pipe are some of the used within the oil & gas industries.

- Our Stainless Steel Pipe 316l Seamless products can be used in boats, marine applications, sea water purification methods and in waste water management purposes as properly.

Trade Item�� EXW,FOB,CNF,CIF,CFR

Stock Thickness: 0.1-200.0mm

Production thickness: 0.5.0-200mm

Width: 600-3900mm

Length: 1000-12000mm

Grade:

200 series: 201,202

300 series: 301,304,304L,304H,309,309S,310S,316L,316Ti,321,321H,330

400 series: 409,409l,410,420J1,420J2,430,436,439,440A/B/C

Duplex: 329,2205,2507,904L,2304

Surface: No.1,1D,2D,2B,NO.4/4K/hairline,satin,6k,BA,mirror/8K

Even if austenitic steels are typically non-magnetic, they’ll present some magnetic property based on the actual alloy composition and the work hardening given throughout production. Austenitic stainless steels are divided into the collection 200 (chromium-manganese-nickel alloys) and 300 (chromium-nickel alloys like 304, 309, 316, 321, 347, etc). Grade 304/304L is the most typical austenitic chrome steel that fits most corrosive purposes. Any different grade within the 300 collection enhances the fundamental options of SS304.

Standard specification for iron-nickel-chromium-molybdenum alloys (UNS N08366 and UNS N08367) seamless pipe and tube. Duplex can be immune to chloride corrosion cracking (SCC) at temperatures as much as about a hundred and fiftyºC.

These forms of stainless steels are magnetic however to a decrease extent than ferritic, martensitic and precipitation hardening grades because of the 50% austenitic content material. Duplex pipes 2205 (UNS S31803/UNS S32205) are used for applications beneath 600 degrees (F). Nevertheless, the basic austenitic grades are susceptible to stress corrosion cracking (larger percentages of nickel are necessary to reinforce the stress corrosion cracking). Austenitic stainless-steel cannot be hardened by heat treatment however have can work hardened to high power ranges while retaining a reasonable level of strength and ductility.

The standard stainless-steel pipes dimensions are set by the ANSI ASME B36.19 specification. Duplex stainless steels have a microstructure which is 50% ferritic and 50% austenitic.

We have thousands tons stock of stainless steel sheet and coil with various size and grade,mainly include austenitic stainless steel, martens stainless steel (including precipitation hardened stainless steel sheet & coil), ferritic stainless steel, and duplex stainless steel.

Characteristics of Stainless Steel Sheet and Plate:

High corrosion resistance

High strength

High toughness and impact resistance

Temperature resistance

High workability, including machining, stamping, fabricating and welding

Smooth surface finish that can be easily clean