1.4310 aisi 301 stainless-steel supplier

We produce ASTM/ASME Grade 304, Grade 304L,304h, 316, 316L, 316H, 316TI, 321, 321H, 309S, 309H, 310S, 310H, 410S, 2205, 904L, 2507, 254, gh3030, 625, 253MA, S30815, 317L, Type 317, 316lN, 8020, 800, 800H, C276, S32304 and others special requirement stainless steel grade.

Pipes with Schedule forty come with normal weight, and pipes with schedule eighty come with extra power. The materials used for making Schedule 40 and Schedule eighty come from the identical materials.

Therefore, duplex pipes mix the qualities of ferritic and austenitic stainless steel supplies. Duplex and super duplex stainless steels are weldable and have moderate formability. These forms of stainless steels are magnetic however to a decrease extent than ferritic, martensitic and precipitation hardening grades because of the 50% austenitic content. The microstructure of austenitic stainless steels is obtained with the addition of nickel, manganese, and nitrogen that give weldability and formability properties to the alloy. The resistance to corrosion may be additional improved by augmenting the proportion of chrome, moly, and nitrogen to the base alloy.

B31.3The design pressure of every element in a piping system shall be not less than the pressure on the most extreme condition of coincident inner or external pressure and temperature expected throughout service, except as provided in par. 302.2.4.The design temperature of every part in a piping system is the temperature at which, under the coincident strain, the best thickness or highest element rating is required in accordance with par.

Our stainless production range

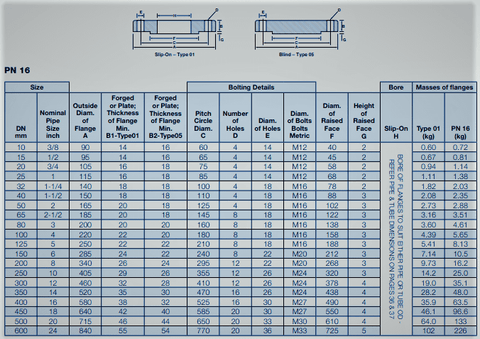

Pressure Temperature Rating (Pt-score)

- Several grades of metal shall conform to the required chemical composition for carbon, manganese, phosphorus, sulfur, silicon, chromium, nickel, molybdenum, titanium, columbium, tantalum, nitrogen, vanadium, copper, cerium, boron, aluminum, and others.

- All pipes shall be furnished in the heat-treated condition in accordance with the required heat treating temperature and cooling/testing necessities.

- This guide covers normal specification for seamless, straight-seam welded, and chilly labored welded austenitic chrome steel pipe supposed for high-temperature and common corrosive service.

The addition of such alloying elements enhances the resistance of the metal to corrosion in harsh purposes. lists the standardized dimensions of welded and seamless chrome steel pipe as proven in ASME B36.19. Pipe having other dimensions is permitted to be ordered and furnished offered such pipe complies with all other requirements of this specification. Higher strain rating means greater wall thickness and higher weight which in flip increases the purchase price, set up cost, maintenance cost, and extra space requirement. So, if a piping element will work at a decrease stress ranking and there are no other elements to consider, like material composition or connection sort, buying a part at a decrease cost is a no-brainer.

“Schedule 40” and “Schedule eighty” check with the thickness of the partitions of pipes. “Schedule” is the usual of wall thickness that has been adopted by the American National Standards Institute.

The pipe pressure ranking for the same material adjustments at totally different temperatures. For the identical materials and constant design pressure, completely different pressure ratings are applicable over totally different ranges of design temperatures. As the design temperature increases the strain rating requirement for the pipe also will increase for the same design strain. All Pipes and various pipe fittings are mostly classified based on their strain temperature score or commonly often known as P-T Rating.

Pressure Rating

As per the Institute, the thickness of wall pipes varies from Schedule 10, Schedule forty, Schedule 80, and Schedule 160. Grade 2205 duplex will typically perform properly in environments which trigger premature failure of the standard austenitic grades of sequence 300 stainless steel.

Which is better MS or GI?

by the pipe NPS minus double the pipe wall thickness (which can be obtained from the pipe schedule). For example, for a 12 NPS (DN 300 mm) pipe, schedule 40, the OD and wall thickness are respectively 12.75 inches (324 mm) and 0.406 inches (10.4 mm). Thus: Pipe ID = 12.75 inches – 2 x 0.406 inches = 11.94 inches, or.

We have thousands tons stock of stainless steel sheet and coil with various size and grade,mainly include austenitic stainless steel, martens stainless steel (including precipitation hardened stainless steel sheet & coil), ferritic stainless steel, and duplex stainless steel.

Characteristics of Stainless Steel Sheet and Plate:

High corrosion resistance

High strength

High toughness and impact resistance

Temperature resistance

High workability, including machining, stamping, fabricating and welding

Smooth surface finish that can be easily clean