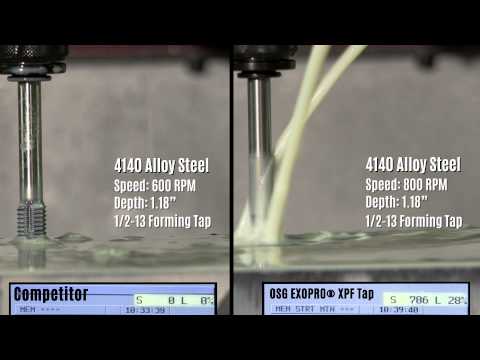

Aisi 4140 Alloy Steel

We produce ASTM/ASME Grade 304, Grade 304L,304h, 316, 316L, 316H, 316TI, 321, 321H, 309S, 309H, 310S, 310H, 410S, 2205, 904L, 2507, 254, gh3030, 625, 253MA, S30815, 317L, Type 317, 316lN, 8020, 800, 800H, C276, S32304 and others special requirement stainless steel grade.

Content

AISI 4140 steel is a low alloy steel containing chromium, molybdenum, and manganese. It is extensively used across numerous industries and is an excellent materials alternative due to its toughness, excessive fatigue strength, and abrasion and impact resistance. Not many grades can match the flexibility and usefulness of 4140. Ballistic Advantage is a top quality manufacturer of AR10 and AR 15 rifle barrels and AR substitute components.

Our precision barrels are manufactured in Chrome molly steel with QPQ Melonite finish or in shiny bead blasted Stainless Steel. This Chromium forms a passive movie of Chromium Oxide in regards to the outer surface which prevents corrosion by blocking oxygen diffusion on the surface and preventing its spread into the internal construction of the metal. A major consider metallic hardness is its proportion by weight of Carbon. Metal has a crystalline structure and the small Carbon atoms discover their means in-between the iron atoms when alloys are heated, strengthening the crystalline structure. By rapidly cooling the heated metallic the Carbon atoms are frozen in place resulting in a a lot stronger and harder steel.

No, because of much less fouling and better finishes the Stainless barrel is up to 30% more accurate than its Chrome Moly counterpart as long as you are not frequently firing the firearm and heating up the barrel. Due to the low yield energy as said above Stainless Steel has a a lot smaller effective temperature vary of use. Many tests have been carried out about the longevity of Alloy steel barrels verses Stainless Steel rifle barrels. Chrome Moly barrels all the time outlast Stainless Steel barrels however only by a slim margin.

Length: 2000mm, 2438mm,2500mm,3000mm,6000mm,or required

Our stainless production range

- And with such a high temperature tensile energy and corrosion resistance, CrMo can be effective in salt-water applications.

- For instance, the added tensile energy and additional corrosion resistance means chrome moly is good for environments with an elevated temperature stage (beyond that of straightforward Mo-primarily based steels) .

- So any industries or applications that function tools under high temperatures can profit from utilizing chromium molybdenum alloys.

- These industries include oil and fuel, vitality, automotive, steel manufacturing, and forming gear .

This added energy and corrosion resistance signifies that CrMo steel is used when the energy offered by gentle carbon metal isn’t sufficient. These benefits give chrome moly added reliability, which is why it’s utilized in so many various applications. AISI 4140 alloy metal may be welded utilizing all standard techniques. However, the mechanical properties of this steel shall be affected whether it is welded within the warmth-handled situation, and submit-weld heat therapy ought to be performed. It may be formed utilizing conventional methods in the annealed situation.

4140 Annealed could have a hardness in the excessive teens/low twenties on the Rockwell C Scale. 4140 HT is essentially the most commonly used excessive tensile steel with infinite functions including everything from gears and pumps to varied applications within the automotive and development business. It’s clear you need the right steel to ensure strong and long-lasting gear. And chromium molybdenum alloy is right for many functions and industries, because of its hardness and corrosion resistance.

Heat Treatment

The Cr additionally supplies good hardness penetration, and the Mo content ensures the hardness is uniform . AISI 4140 alloy steel could be tempered at 205 to 649°C (four hundred to 1200°F) depending upon the desired hardness stage. The hardness of the metal may be elevated if it has a decrease tempering temperature. For instance, a tensile strength of 225 ksi could be achieved by tempering at 316°C (600°F), and tensile power of one hundred thirty ksi could be achieved by tempering at 538°C (a thousand°F). 4140 Annealed is often used when excessive tensile energy or toughness is required.

It requires more stress or pressure for forming as a result of it is more durable than plain carbon steels. The following desk outlines the mechanical properties of AISI 4140 alloy steel.

We have thousands tons stock of stainless steel sheet and coil with various size and grade,mainly include austenitic stainless steel, martens stainless steel (including precipitation hardened stainless steel sheet & coil), ferritic stainless steel, and duplex stainless steel.

Characteristics of Stainless Steel Sheet and Plate:

High corrosion resistance

High strength

High toughness and impact resistance

Temperature resistance

High workability, including machining, stamping, fabricating and welding

Smooth surface finish that can be easily clean