ASTM A240 304h stainless

Content

304h stainless round bar

Gangsteel produce and export ASTM A240 304H stainless steel plate, ASTM A240 TP304H Stainless Steel No.1 Finish Plate and we supply TP304H stainless steel stock list thickness 2mm to 300mm at Origin China. We are the large stainless material factory supplier in China.

To put them to work in your favor, it is good to pay attention to them. You can flip to an extended tutorial for getting a laser chopping quote. If you might be in search of tube chopping, we additionally supply that with instant quoting. Upload your STP files to the platform for an instant quote.

304h stainless plate

- CNC machining services for aluminum, brass, bronze alloys, metal, copper, nickel silver, chrome steel, titanium, PEEK, ABS and PTFE materials.

- Industries served include industrial lighting, automotive, medical, agriculture, off-road automobiles, telecommunications, electronics, and meter elements industries.

- Specializes in medium to massive production runs.

- Prototype and low to excessive run manufacturing volume are available.

- Capable of machining elements from 0.01 to 1 5/eight in.

High quality machining starting from easy manufacturing parts to complex 4th axis functions. Materials include plastics, aluminum, copper, brass, bronze, carbon steels, alloys, stainless-steel, software steels, Inconel½½ & Monel½½. 4th axis vertical & horizontal machining & standard machining capabilities. Services embody turning, horizontal milling, vertical milling, deep hole drilling, grinding, honing, welding, broaching, plating, heat treating & complete tooling & fixturing. Ferritic stainless steels typically have higher engineering properties than austenitic grades, but have decreased corrosion resistance, due to the lower chromium and nickel content material. They contain between 10.5% and 27% chromium and very little nickel, if any, however some varieties can contain lead.

304h material equivalent|304h thermal expansion|304h stainless steel equivalent|304h din|aisi 304h datasheet|304h 304l difference|john deere 304h parts|304h stainless steel density|304h round bar houston|304h bmtc bus route|304h allowable stress|304h alloy|aisi 304h stainless steel|a479 304h|304h angle|304h astm|304 honey|304 help|304h tubing|a358 304h|astm 304h stainless steel|304h bearing|304h barden|304h bolts|b-304h|304h bar|304h bar stock|a 312 tp 304h|a 240 304h|304h bus route|aisi 304h equivalent|304h pipe europe|hb-304h|veh-304hpd-h|what is 304h stainless steel|

Our standard lead-time is 5 business days for prototype and brief-run laser chopping jobs, but there are options during checkout for lead-times as fast as same-day when sufficient material is in stock. We guarantee whatever lead-time you select throughout checkout, but we’ll reduce your job early when we can. Also, these Stainless Steel 304L Slatting Plates are again and again plated in the company of nickel or chrome for a better finish and superior resistance to corrosion. These Stainless Steel 304H Slatting Coils are a hassle-free and profitable method to plug your pipe.

Pulsed arc welding is the preferred method. 254SMo can be joined to itself and to many other metals by typical welding processes. For welding, 254SMo must be within the soft-annealed or stress relieved condition and be free from scale, grease and markings. High resistance to oxidation, and could also be used in continuous service as much as 2000ºF (1100ºC) offered reducing sulphur gases usually are not current. Applications requiring high fatigue power, good resistance to galling, seizing, and stress corrosion. I was beforehand utilizing a waterjet to cut 0.062 aluminum and some holes needed to be cut undersized then drilled to fit a pressnut. With Oshcut I measured these holes to be inside 0.002″. No have to drill!! I am actually impressed with the quality.

ASTM A240 TP304H Stainless Steel Plates

Grade 430F is the free-machining model of this grade, out there in bar form to be used in automatic screw machines. Grade 434 is the molybdenum bearing version of Grade 430 and has the identical helpful combination of properties. Its molybdenum addition improves corrosion resistance. Stainless metal largely used to manufacture shafts in numerous size or form. Shafts producer use chrome steel because steel offers many good traits like toughness, power and good flawless ending. In this blog, we will discuss why chrome steel used in CNC machining instruments. Significant quantities of manganese have been utilized in many chrome steel compositions.

ASTM A240 TP304H Stainless Steel Hot Rolled Plates

304H stainless steel belt, SUS304H stainless steel belt, 304H stainless steel belt, 0Cr18Ni9, 304-general model; namely 18/8 stainless steel. The GB grade is 0Cr18Ni9.

Vickers hardness (HV) 370°-420° and Hardness tolerance (HV) ±20°

Relative Keywords:

304h|304 house|304h stainless steel|304h vs 304l|304h stainless|304h chemical composition|304h pipe|304h ss|304h material|inox 304h|sa 240 304h|veh-304hcd-k|304h round bar|304h stainless steel properties|has-304h|304h plate|super 304h chemical composition|cdv2-304hn n|f304h|a240 304h|f-c304h|304h sheet|304h edelstahl|c304h|super 304h composition|lfd-304h|s-304h-cct|est-304h|veh-304hcc-k|304h vs 304|304h pipe suppliers|hlh-304h|304h steel|304h stainless steel round bar|304h stainless steel sheet|304h fittings|304h vs 304l stainless steel|s-304h-ab|304h composition|304h stainless steel composition|304h stainless steel temperature limits|yt-304h|welding 304h stainless steel|304h werkstoff|aisi 304h properties|304h outokumpu|zinsser 304h|cdv2-304hn n pdf|density of 304h stainless steel|

a240 Type 304H widely used material.

Corrosion resistance, heat resistance, good mechanical properties, good processing performance at room temperature such as deep drawing, bending, etc., will not harden after heat treatment, can withstand general rust in the building, and can resist erosion by food processing media (but contains concentrated acid

Corrosion may occur due to high temperature and chloride components), and it can resist organic compounds, dyes and a wide variety of inorganic compounds.

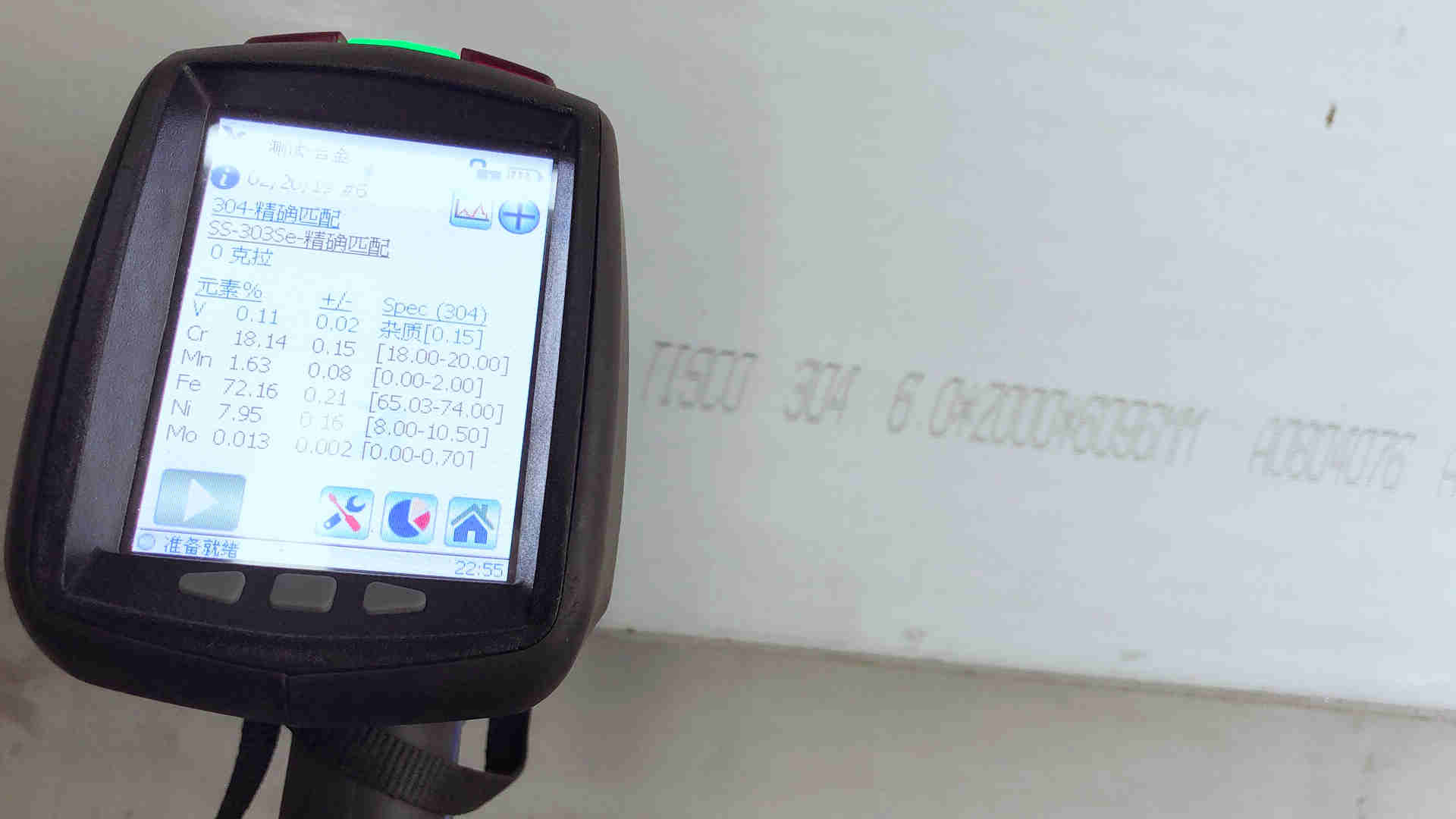

ASTM A240 Stainless Steel 304H Chemical Composition

| Type |

Grade |

ASTM A240 Chemical Composition |

|||||||||

|

ASTM(A240M) |

Others(JIS) |

C |

Si |

Mn |

P |

S |

Ni |

Cr |

Mo |

Others |

|

|

Austenitic Steels |

|||||||||||

|

304H |

0.04/0.10 |

≤0.75 |

≤2.00 |

≤0.045 |

≤0.030 |

8.0/10.5 |

18.0/20.0 |

― |

|||

A240 Type 304L (low carbon), good resistance to nitric acid, and durable for medium temperature and concentration of sulfuric acid, widely used as liquid gas storage tanks, low temperature equipment (304N), appliances and other consumer products, kitchen equipment, hospital equipment, transportation Tools, wastewater treatment equipment.

Alloy 304 (S30400), 304L (S30403), and 304H (S30409) stainless steels are 18% chromium, 8% nickel austenitic alloys, which are the most common and commonly used alloys in the stainless steel family. Because these alloys have one or more of the following properties, they can be used in various applications.

Properties include:

STM A240 TP304H Stainless Steel Plate Physical Properties

| Grade |

Density (kg/m3) |

Elastic Modulus (GPa) |

Mean Coefficient of Thermal Expansion (m/m/0C) |

Thermal Conductivity (W/m.K) |

Specific Heat 0-1000C (J/kg.K) |

Electrical Resistivity (n.m) |

|||

|

0-1000C |

0-3150C |

0-5380C |

at 1000C |

at 5000C |

|||||

|

304H |

8000 |

193 |

17.2 |

17.8 |

18.4 |

16.2 |

21.5 |

500 |

720 |

A high-alloy steel A240 304h that can resist corrosion in the air or in chemically corrosive media. It has a beautiful surface and good corrosion resistance. It does not need to undergo surface treatment such as plating, but exerts its inherent surface properties. It is used in various steels.

One kind, usually called stainless steel.

High alloy steels such as 13 chromium steel and 18-chromium nickel steel are representative of performance.

Others relative stainless keywords:

what is 304h material| 304h |304h plate in houston|304h hardness|304h high temperature|304h hardness brinell|304h pipe houston|what is 304h stainless|aço inox 304h|jis 304h|304h loader|304h larson miller|lnt 304h|304h john deere loader|304h john deere|tube inox 304h|acero inoxidable 304h|soudage inox 304h|gatunek 304h|sa240 gr 304h|304h pipe and fittings|stainless steel 304h flanges|304h stainless steel fittings|f304h vs f304|304h ferrite number|304h filler metal|304 h en minute|304h flat bar|304h flanges|f304h chemical composition|f304h equivalent|304h grain size|304h grade|gd-304h|a240 gr 304h|sus f304h|werkstoff f304h|sa 182 f 304h|a182 f304h chemical composition|a182 f304h temperature|lnm 304h|

From a metallographic point of view, because stainless steel contains chromium, a very thin chromium film is formed on the surface. This film isolates the intruding oxygen from the steel for corrosion resistance.

In order to maintain the inherent corrosion resistance of stainless steel, steel must contain more than 12% chromium

SS 304H Plate Equivalent grades

| STANDARD |

WERKSTOFF NR. |

UNS |

JIS |

AFNOR |

BS |

GOST |

EN |

|

SS 304H |

1.4948 |

S30409 |

– |

– |

– |

– |

– |

304, 304L, and 304H alloys are the most prone to stress corrosion cracking (SSC) among austenitic stainless steels because of their relatively low nickel content.

The conditions that cause stress corrosion cracking are: (1) the presence of halide ions (usually chloride), (2) residual tension, and (3) the temperature exceeds 120°F (49°C).

Cold deformation during alloy forming, stenting into tube sheet, welding operations, etc. can all cause stress.

Annealing and stress relief heat treatment after cold deformation can reduce stress, thus reducing the possibility of halide stress corrosion cracking.

In the environment that may cause intergranular corrosion, it is best to choose low-carbon 304L alloy when working under low-temperature annealing.

AASTM A240 Stainless Steel 304H Plate Mechanical Properties

| Type |

Mechanical Properties for Stainless Steel Plates, Stainless Steel Sheet |

|||||||

|

ASTM(A240M) |

Others(JIS) |

Tensile Properties |

Hardness |

|||||

|

Yield Strength (Mpa) |

Tensile Strength (Mpa) |

Elongation (%) |

HBW |

HRBW |

||||

|

AusteniticSteels |

||||||||

|

304H |

≥205 |

≥515 |

≥40 |

≤201 |

≤92 |

|||

Manganese preserves an austenitic construction within the metal as does nickel, however at a decrease cost. High oxidation-resistance in air at ambient temperature is often achieved with additions of a minimal of thirteen% chromium, and up to 26% is used for harsh environments. The chromium types a passivation layer of chromium oxide when exposed to oxygen. The layer is simply too thin to be seen, and the metal remains lustrous. The layer is impervious to water and air, protecting the steel beneath. Also, this layer quickly reforms when the surface is scratched. This phenomenon is known as passivation and is seen in other metals, corresponding to aluminium and titanium.

density of 304h|nssw yt-304h|304h plate suppliers|304h properties|304h oj-201|304l or 304h|304 or 304h|304h 1.4948|suppliers of 304h stainless steel|sensitization of 304h stainless steel|ss 304h material|304h 304|ldm-304h-xy|l-304 hd|304h 304l|lincoln lnt 304h|sa-479-304h|ldm-304h|linija 304h|304 hp l|304h material properties|super 304h material|y2-304h|304h p number|304h metallurgy|sa-240 304h properties|304h material composition|304h mechanical properties|304h means|n-304h|304h pwht|thermanit 304h|temperature 304h|t-304h|type 304h|tbi 304h|304h tensile strength|304h tig wire|tp 304h stainless steel|304h uns|304h plate uk|304h vs 347h|304h vs 316h|304h vs 316|304h stainless steel use|304h vs 304 ss|304h vs 310|304h stainless steel uk|304h vs 321h|s304h|s-304h-cctk|304h temperature range|304h stainless round bar

Most compositions embody molybdenum; some, aluminium or titanium. Common ferritic grades embody 18Cr-2Mo, 26Cr-1Mo, 29Cr-4Mo, and 29Cr-4Mo-2Ni. These alloys can be degraded by the presence of σ chromium, an intermetallic part which might precipitate upon welding. Stainless metal€™s resistance to corrosion and marking, low maintenance, relatively low value, and acquainted lustre make it an ideal materials for many purposes. There are over one hundred fifty grades of stainless-steel, of which fifteen are mostly used.

sa 240 304h

Capabilities embody drilling, knurling, cutting, profiling, reaming, rotary splining, turning, dealing with and counterboring. Prototype and low to excessive quantity manufacturing offered A240 SS304H Stainless factory. Serves the aerospace, agricultural, transportation, automation, automotive, building, defense, electronics, marine, medical, military, robotics and different industries.

Grade 303 is most readily machining stainless steel grade. The high machineable nature of grade 303 is because of high desire of sulphur in metal composition. The desire for sulphur affects general corrosion resistance & toughness of grade 303.

Milling, drilling, boring, turning, threading, knurling, broaching, counterboring, reaming, countersinking, cutting and facing companies are available. Capabilities include prototyping, high and low volume manufacturing, Six Sigma and lean manufacturing. Secondary companies include meeting, plating, urgent, passivating, heat treating, anodizing, etching and chromating. Industries served embody agricultural, automotive, construction, military, petrochemical, electronics, diary, dental, marine, mining, aerospace, business, authorities, medical, oil/gas, meals and beverage. Meets ANSI, ASME, ASTM, AWS and DOT standards.

|what is 304h|rx-304h|304h yield strength|304h vs 316l|p-304h-ab|304h round bar uk|john deere 304h wheel loaders|sharp rp-304h|304h stainless steel data sheet|304h stainless steel chemical composition|john deere 304h loader specs|304h welding wire|304h welding|304h rohre|super 304h welding|304h pipe stock|tole inox 304h|husky c304h air compressor|304h data sheet|304h density|deere 304h specs|p-304h-cct|crane 304h cam|304h carbon content|304h chemistry|304h coefficient of thermal expansion|304h creep strength|deere 304h|deere 304h for sale|304h equivalent|

Gangsteel mainly products are 304h Square tube,304h stainless,304h Rectangular tube,304h seamless pipes,304h seamless tubes,304h welded pipes,304h angle bar,304h H Beam,304h channel beam,304h round bar ,304h cutting part,304h machine part,304H CNC cutting parts,304H water jet cutting parts,304H laser cutting parts and stainless steel 304h. If you have requirement, please contact us by email admin@gangsteel.com