1.4307 aisi 304l stainless-steel provider

We produce ASTM/ASME Grade 304, Grade 304L,304h, 316, 316L, 316H, 316TI, 321, 321H, 309S, 309H, 310S, 310H, 410S, 2205, 904L, 2507, 254, gh3030, 625, 253MA, S30815, 317L, Type 317, 316lN, 8020, 800, 800H, C276, S32304 and others special requirement stainless steel grade.

Its low carbon content makes it appropriate for many welding operations which are widespread in building and different industries. 304L also offers for wonderful rust resistance and low intergranular corrosion. 304, like all austenitic steels, is non-magnetic in nature, and it additionally features low electrical and thermal conductivity. It also is recognized for its higher corrosion resistance than most other chrome steel alloys. Alloy 303 is a non-magnetic, austenitic stainless-steel that isn’t hardenable by warmth treatment.

The commonest excessive-temperature gaseous mixture is air, of which oxygen is the most reactive component. To avoid corrosion in air, carbon metal is restricted to roughly 480 °C (900 °F).

304 stainless-steel accommodates chromium-nickel content material and low carbon. This stainless steel type is oxidation and corrosion resistant. This sturdiness offers ease for fabrication and prevention of product contamination. 304 chrome steel is taken into account probably the most versatile and common austenitic chrome steel. 304 stainless steel is more cost effective compared to 316 chrome steel.

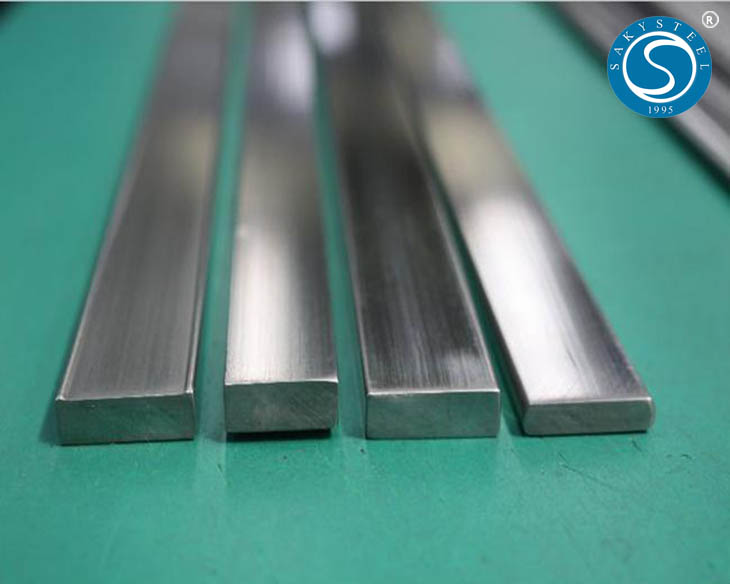

Our stainless production range

- Clinton Aluminum keeps a grade often known as 304L #4 end stainless-steel sheet in inventory.

- 304, like all austenitic steels, is non-magnetic in nature, and it additionally features low electrical and thermal conductivity.

- 304 stainless-steel, among the most popular chrome steel alloys, has a minimum of 18% chromium and 8% nickel.

- Its low carbon content material makes it suitable for many welding operations which are common in development and other industries.

Are all stainless steel food grade?

Unfortunately, yes. Through normal wear and tear, the metals in stainless steel will leach into food (source). Cooking acidic foods will cause the pot to leach higher amounts. In general, nickel leaches in higher amounts than the other metals.

Other gases, similar to sulfur dioxide, hydrogen sulfide, carbon monoxide, chlorine, additionally attack stainless steel. Resistance to other gases relies on the type of fuel, the temperature, and the alloying content material of the chrome steel. When deciding on a stainless steel that must endure corrosive environments, austenitic stainless steels are typically used. Possessing wonderful mechanical properties, the excessive amounts of nickel and chromium in austenitic stainless steels additionally present outstanding corrosion resistance.

It is the free machining modification of the fundamental 18% chromium / eight% nickel stainless-steel. Like other austenitic grades, Alloy 303 demonstrates wonderful toughness, though the sulfur does scale back this somewhat as nicely. Stainless steels have a protracted history of utility in contact with water as a result of their excellent corrosion resistance.

Heat Resistance Of Stainless Steel Alloy 303

Additionally, many austenitic stainless steels are weldable and formable. Two of the more commonly used grades of austenitic stainless steel are grades 304 and 316. To assist you to decide which grade is correct in your project, this weblog will look at the distinction between 304 and 316 chrome steel.

Stainless Steel Families

This means that they’re a metallic, non-magnetic iron allotrope containing chromium and nickel, with different components added for specific grades. They have a eutectoid point of no less than 727°C (1,341°F). The austenite allotrope exists at room temperature in stainless-steel and was initially named for Sir William Chandler Roberts-Austen. These metals are typically labeled within the 200 and 300 sequence of stainless-steel. 303 SS is a free-machining, austenitic chrome steel that is used primarily for parts requiring machining, grinding or sharpening.

We have thousands tons stock of stainless steel sheet and coil with various size and grade,mainly include austenitic stainless steel, martens stainless steel (including precipitation hardened stainless steel sheet & coil), ferritic stainless steel, and duplex stainless steel.

Characteristics of Stainless Steel Sheet and Plate:

High corrosion resistance

High strength

High toughness and impact resistance

Temperature resistance

High workability, including machining, stamping, fabricating and welding

Smooth surface finish that can be easily clean