1.4034 material chrome steel supplier

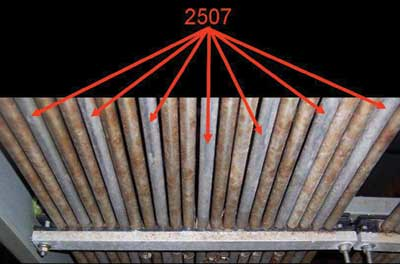

We produce ASTM/ASME Grade 304, Grade 304L,304h, 316, 316L, 316H, 316TI, 321, 321H, 309S, 309H, 310S, 310H, 410S, 2205, 904L, 2507, 254, gh3030, 625, 253MA, S30815, 317L, Type 317, 316lN, 8020, 800, 800H, C276, S32304 and others special requirement stainless steel grade.

What is the life expectancy of stainless steel?

’18/8′ is probably the most commonly used stainless steel and contains 18% chromium and 8% nickel. This steel is also known as ‘304’ (in the American AISI grade designation system) or 1.4301 in the European BS EN 10088 standard.

The 300 series encompass austenitic chromium-nickel alloys. Austentic incorporates a maximum of 0.15% carbon and a minimal of sixteen% chromium, and nickel is the essential alloying component. This creates superior corrosion resistance and ease of fabrication. Austentic chrome steel has a wide range of mechanical properties and can stand up to a variety of temperatures. Austenitic grades are essentially the most generally used stainless steels, and aren’t hardenable by heat therapy.

The chromium combines with the oxygen before the iron is able to which types a chromium oxide layer. This layer could be very corrosion resistant which prevents rust formation and protects the underlying steel. On the other hand, ferritic or martensitic stainless steels could also be vulnerable to rust because they comprise much less chromium.

300 Series ApplicationsType 301 High strength grade, with resistance to ambiance corrosion. Its brilliant, enticing floor make it a superb alternative for decorative structural purposes.Type 302Used for a wide variety of house & business functions. One of probably the most familiar & incessantly used alloys in the stainless-steel family. Examples include Refrigerators, Dishwashers, and Washing machinesType 303A non-magnetic austenitic chrome steel specifically designed to exhibit improved machinability.

Stock Thickness: 0.1-200.0mm

Production thickness: 0.5.0-200mm

Width: 600-3900mm

Length: 1000-12000mm

Grade:

200 series: 201,202

300 series: 301,304,304L,304H,309,309S,310S,316L,316Ti,321,321H,330

400 series: 409,409l,410,420J1,420J2,430,436,439,440A/B/C

Duplex: 329,2205,2507,904L,2304

Surface: No.1,1D,2D,2B,NO.4/4K/hairline,satin,6k,BA,mirror/8K

- The 300 sequence encompass austenitic chromium-nickel alloys.

- Austenitic grades are the most generally used stainless steels, and are not hardenable by warmth treatment.

- This creates superior corrosion resistance and ease of fabrication.

- Austentic accommodates a maximum of 0.15% carbon and a minimum of sixteen% chromium, and nickel is the essential alloying component.

- Austentic chrome steel has a wide range of mechanical properties and may withstand a variety of temperatures.

Popular ferritic stainless steels are iron-chromium binary alloys with 13 to 18 percent chromium. These alloys are ferromagnetic at room temperature. The hottest chrome steel is Type 304, which accommodates roughly 18 % chromium and 8 percent nickel. If the alloy is mechanically deformed, i.e. bent, at room temperature, it’ll partially transform to the ferritic part and shall be partly magnetic, or ferromagnetic, as it is more exactly termed. The metallic atoms in an austenitic stainless steel are arranged on a face-centered cubic (fcc) lattice.

Metal Spinning Stainless Steels (300 And 400 Series)

Medical and pharmaceutical components and parts are widespread functions.Type 304Used for all kinds of house and industrial purposes. Another regularly used alloy, together with purposes the place good corrosion resistance & excellent drawing capacity is required. Stainless steels have a protracted history of software in contact with water as a result of their glorious corrosion resistance. Applications embody a spread of situations together with plumbing, potable water and wastewater therapy, desalination, and brine remedy.

The excessive Chromium and Nickel content of the grades on this group present superior corrosion resistance and superb mechanical properties. They cannot be hardened via heat remedy, however can be hardened considerably by way of chilly-working. None of the grades in this class are magnetic. Martensitic Stainless grades are a bunch of stainless alloys made to be be corrosion resistant and harden-able (using heat treating). All martensitic grades are straightforward chromium steels without nickel.

Some 300 collection, corresponding to Type 316, additionally comprise some molybdenum to promote resistance to acids and improve resistance to localized assault (e.g. pitting and crevice corrosion). The “L” grades are used to offer further corrosion resistance after welding. The letter “L” after a chrome steel grade number signifies low carbon.

We have thousands tons stock of stainless steel sheet and coil with various size and grade,mainly include austenitic stainless steel, martens stainless steel (including precipitation hardened stainless steel sheet & coil), ferritic stainless steel, and duplex stainless steel.

Characteristics of Stainless Steel Sheet and Plate:

High corrosion resistance

High strength

High toughness and impact resistance

Temperature resistance

High workability, including machining, stamping, fabricating and welding

Smooth surface finish that can be easily clean