1.4306 material stainless steel provider

We produce ASTM/ASME Grade 304, Grade 304L,304h, 316, 316L, 316H, 316TI, 321, 321H, 309S, 309H, 310S, 310H, 410S, 2205, 904L, 2507, 254, gh3030, 625, 253MA, S30815, 317L, Type 317, 316lN, 8020, 800, 800H, C276, S32304 and others special requirement stainless steel grade.

They are used universally for standard building parts but are also the fundamentals for subsequent finishing processes that alter the surface to fulfill more demanding necessities. From mill finishes to applied finishes, the chrome steel finishes which are applied to the floor of your stainless-steel can play an even bigger role than you could notice. Consequently, 316L is used when welding is required to ensure maximum corrosion resistance.

Commonly brushed metals embody stainless steel, aluminium and nickel. Brushed finishes are in style in both small home equipment and whiteware, and feature in structure and automotive design. The Gateway Arch and DMC DeLorean are each clad in brushed chrome steel.

What Is A 2b Finish On Stainless Steel?

The drawbacks to this finish embrace reduced corrosion resistance, because the grooves of the end are susceptible to rust. The finish is produced by ‘cold rolling’ stainless steel through special rolls or dies.

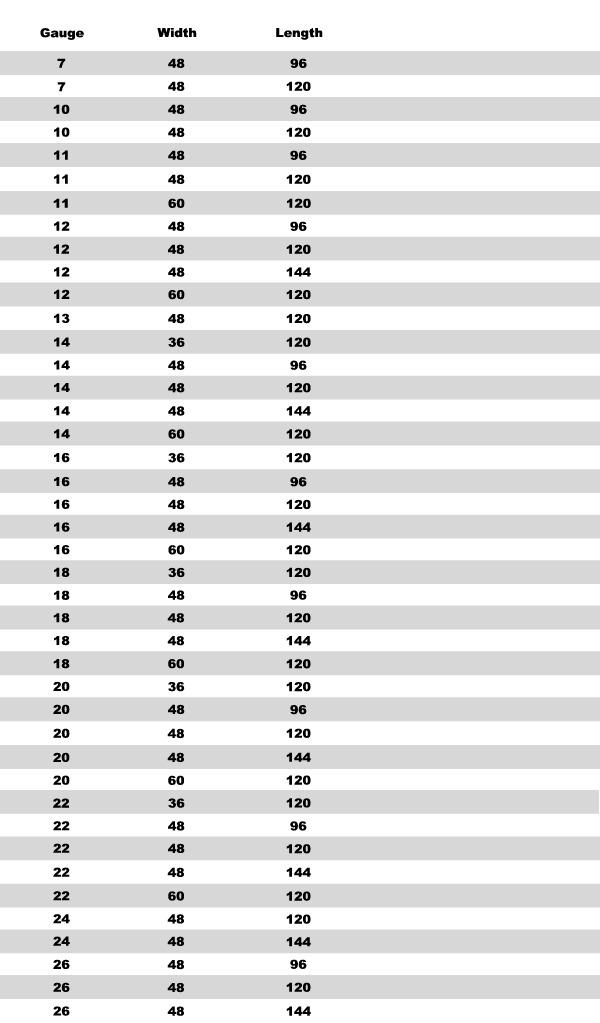

Our stainless production range

- A No. 2D is a refined surface end that’s achieved by chilly rolling, heat treating and pickling.

- A No. 2D finish retains lubricants properly, making it interesting for deep drawing.

- Its low reflective matt floor appearance makes it suitable for industrial and engineering wants however, architecturally, also suitable for less critical aesthetic functions.

- A moderately tough and boring surface, a No. 1 Finish includes rolling stainless steel that has been heated previous to rolling (hot-rolling).

The larger the abrasive grit used, the finer and extra reflective the look. For example, one frequent utilized end is #4, which you can see on your common restaurant or kitchen equipment, meals processing or dairy gear, and elsewhere. This finish makes use of between one hundred twenty and 320 abrasive grit, depending on the application. The level of the grit impacts the surface roughness, which is usually measured when it comes to micro-inches or micro meters, represented as Ra (roughness average).

A No. 4 finish is mostly used for restaurant and kitchen equipment, storefronts and meals processing and dairy equipment. A No. 2B end is essentially the most extensively used stainless steel surface finish and is produced very similar to the No. 2D finish. Cold rolled, warmth handled, pickled and pinch handed – this can be a bright chilly rolled finish except that the ultimate light chilly rolling move is completed utilizing polished rolls. The result is a extra reflective end that resembles a cloudy mirror. It is especially frequent in industrial, chemical and meals processing purposes but also used in some architectural purposes that will not be intently examined for uniformity of end.

Alternatively a special rolling procedure is used which can simulate the looks of mechanical abrasion. For this stage, it is essential to take away deep scratches as any floor defects shall be very noticeable on the completed product.

How can I tell if my stainless steel is 304 or 316?

#4 Finish – Also called brushed, directional or satin finish. A number 4 finish is characterized by fine polishing grit lines that are uniform and directional in appearance. The final abrasive used in the process is 150 to 220 grit.

What Are The Different Finishes Of Stainless Steel?

Stainless metal incorporates iron, chromium, manganese, silicon, carbon and, in many instances, vital amounts of nickel and molybdenum. These elements react with oxygen from water and air to form a really skinny, steady movie that consists of such corrosion products as metal oxides and hydroxides. Chromium plays a dominant role in reacting with oxygen to type this corrosion product movie. In truth, all stainless steels by definition contain no less than 10 % chromium. No. 8 Mirror finish is created by mechanically treating the floor with a sequence of progressively finer abrasives.

We have thousands tons stock of stainless steel sheet and coil with various size and grade,mainly include austenitic stainless steel, martens stainless steel (including precipitation hardened stainless steel sheet & coil), ferritic stainless steel, and duplex stainless steel.

Characteristics of Stainless Steel Sheet and Plate:

High corrosion resistance

High strength

High toughness and impact resistance

Temperature resistance

High workability, including machining, stamping, fabricating and welding

Smooth surface finish that can be easily clean