1.4408 ss stainless-steel supplier

We produce ASTM/ASME Grade 304, Grade 304L,304h, 316, 316L, 316H, 316TI, 321, 321H, 309S, 309H, 310S, 310H, 410S, 2205, 904L, 2507, 254, gh3030, 625, 253MA, S30815, 317L, Type 317, 316lN, 8020, 800, 800H, C276, S32304 and others special requirement stainless steel grade.

Content

The Trouble With Gauge Sizes

For instance, grade 316 stainless steel can stand up to caustic solutions and corrosive purposes similar to vapor degreasing or many different parts cleaning processes. Another popular excessive-performing alloy, grade 304 chrome steel is a sturdy materials when it comes to tensile energy, durability, corrosion, and oxidation resistance. The melting point of stainless-steel 304 is reached at temperatures ranging between 2,550 °F – 2,650 °F (1399 °C – 1454 °C).

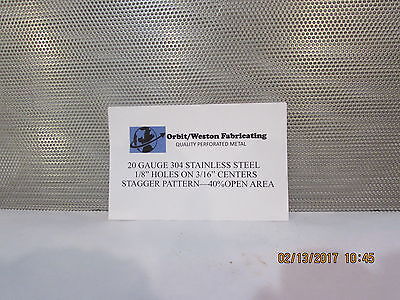

Lastly, a regular exists for Zinc in which a higher gauge quantity signifies a thicker sheet. The chart below can be utilized to find out the equal sheet thickness, in inches or millimeters, for a gauge quantity from the selected gauge measurement commonplace. The weight per unit space of the sheet can also be seen in kilos per square foot and kilograms per sq. meter.

316 SS is extra chemically-resistant in a wide range of purposes, and particularly when dealing with salt and stronger acidic compounds corresponding to lemon or tomato juice. However, due to the low nickel content material, this alloy just isn’t as immune to some dilute lowering acids as grade 316 chrome steel would be. Marlin Steel is a number one manufacturer of custom‐engineered products from steel wire and sheet metal.

Our stainless production range

- Grade 316 has particularly higher resistance to salt and chloride pitting.

- Chloride resistant metals, like grade 16 stainless-steel, are important to make use of for naval purposes or anything involved with chloride.

- Pitting corrosion can happen when stainless steel alloys, such as grade 304 chrome steel, come into contact with salt-wealthy sea breezes and seawater.

Additionally, the melting level of grade 304 chrome steel is a bit greater than that of grade 316. The melting vary of 316 is 2,500 °F – 2,550 °F (1,371 °C – 1,399 °C), roughly 50 to 100 degrees Fahrenheit decrease than the melting level of grade 304 stainless-steel. So let’s speak gauge… There three fundamental gauges used in metal tube panels typically 16 ga, 14 ga, and 10 ga. Gauges work like this; the smaller the quantity the thicker the steel.

Let’s take a look at two alloys which might be usually thought of ideal for many food grade functions, grade 316 stainless steel and grade 430 stainless steel. The elevated nickel content material and the inclusion of molybdenum permits for grade 316 stainless steel to have better chemical resistance than 304 stainless-steel.

But the place grade 316 stainless proves superior is its increased corrosion resistance—notably towards chlorides and chlorinated options. This makes grade 316 stainless significantly fascinating for purposes the place exposure to salt or other powerful corrosives is an issue. If you have an utility with very highly effective corrosives or depends on chlorides, then paying a premium for grade 316 stainless-steel is definitely price it. In such applications, 316 stainless will final many occasions longer than grade 304 stainless-steel would—which can imply many further years of helpful life. Another major difference between 430 and 316 stainless-steel is that grade 430 SS is a ferritic alloy, that means that it’s magnetic by default.

What thickness is 20 gauge in MM?

Because 22-, 24- or 26-gauge sheeting is thicker, and will, therefore, remain more structurally sound over a longer span than a 29-gauge, the building needs fewer supports, which saves your customers money.

16ga steel is .065” inches thick, that’s about 1/sixteenth of an inch thick. 14 gauge in comparison is .083 inches thick which doesn’t sound like a lot except it’s virtually 30% thicker (27.6% to be actual). It most likely originated from the British wire industry earlier than the usual and metric measurement methods had been broadly adopted. At that point, gauges had been used to explain the diameter of the metal wire being drawn.

We have thousands tons stock of stainless steel sheet and coil with various size and grade,mainly include austenitic stainless steel, martens stainless steel (including precipitation hardened stainless steel sheet & coil), ferritic stainless steel, and duplex stainless steel.

Characteristics of Stainless Steel Sheet and Plate:

High corrosion resistance

High strength

High toughness and impact resistance

Temperature resistance

High workability, including machining, stamping, fabricating and welding

Smooth surface finish that can be easily clean