1.4310 ss stainless-steel

We produce ASTM/ASME Grade 304, Grade 304L,304h, 316, 316L, 316H, 316TI, 321, 321H, 309S, 309H, 310S, 310H, 410S, 2205, 904L, 2507, 254, gh3030, 625, 253MA, S30815, 317L, Type 317, 316lN, 8020, 800, 800H, C276, S32304 and others special requirement stainless steel grade.

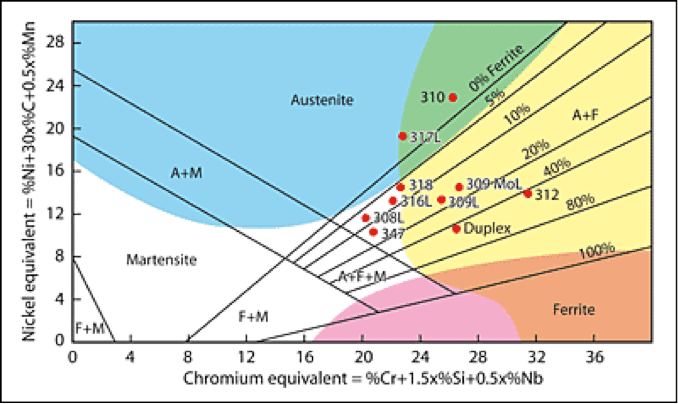

Duplex stainless steels are primarily based around a composition of 22% chromium, whereas super duplex stainless steels are primarily based around a composition of 25% chromium. By increasing the chromium content, the level of pitting corrosion resistance is also increased. However, in order to retain the favourable stability of austenitic and ferritic microstructures, it’s also necessary to extend the content of nickel and other components, which also will increase the price. Hyper duplex stainless steels are now being developed, based around a composition of 27% and 29% chromium, but as but are solely available in tube type, not bar or plate because of difficulties in forging and rolling them.

Significant additions of Mo, Ni and Cu gives this alloy an excellent resistance to pitting and crevice corrosion, particularly in environments containing halide ions e.g. chloride, bromide and fluoride solutions. Alloy 316L is an austenitic stainless steel supplied within the hot labored and annealed condition.

The strength could be tailor-made by adjusting the annealing process, with lower preliminary temperatures leading to larger strengths. The decrease initial temperatures improve the driving force of nucleation. More driving force means more nucleation sites, and extra sites means extra locations for dislocations to be disrupted while the completed half is in use. Sanmac® 2205 is a 22% Cr duplex stainless steel with improved machinability as normal.

What does 316 mean for stainless steel?

Grade 316 is the standard molybdenum-bearing grade, second in importance to 304 amongst the austenitic stainless steels. The molybdenum gives 316 better overall corrosion resistant properties than Grade 304, particularly higher resistance to pitting and crevice corrosion in chloride environments.

Is Type 304 Or 430 Stainless Steel Better For A Gas Grill?

- Duplex stainless steels are based round a composition of twenty-two% chromium, whereas super duplex stainless steels are based around a composition of 25% chromium.

- By rising the chromium content, the extent of pitting corrosion resistance can be increased.

- However, to be able to retain the favourable stability of austenitic and ferritic microstructures, it is also needed to increase the content of nickel and other components, which also will increase the price.

Stock Thickness: 0.1-200.0mm

Production thickness: 0.5.0-200mm

Width: 600-3900mm

Length: 1000-12000mm

Grade:

200 series: 201,202

300 series: 301,304,304L,304H,309,309S,310S,316L,316Ti,321,321H,330

400 series: 409,409l,410,420J1,420J2,430,436,439,440A/B/C

Duplex: 329,2205,2507,904L,2304

Surface: No.1,1D,2D,2B,NO.4/4K/hairline,satin,6k,BA,mirror/8K

Duplex and super duplex belong to a household of stainless steels which might be characterised by a mixture of simple fabrication, high energy and wonderful corrosion resistance. This group of materials is most similar to ferritic and carbon metal, however it has some physical properties according to those present in austenitic chrome steel.

What is martensitic stainless steel used for?

Inconel, a product of Special Metals Corp., has a nickel, chromium and molybdenum composition. Inconel is resistant to corrosion and pitting and comes in several different alloys. Stainless steel is composed of carbon, manganese, phosphorus, sulfur, silicone, chromium and nickel.

The addition of Mo provides the product with much improved corrosion resistance in contrast with Alloy 304, notably with respect to pitting and crevice corrosion in chloride environments. The chromium, tungsten, nitrogen and molybdenum content material in duplex and tremendous duplex create the resistance to crevice corrosion and chloride pitting that makes these supplies so well-liked. These steels even have resistance to chloride stress corrosion which is significantly higher than austenitic grades, without sacrificing on sturdiness or ductility.

It is quickly brake or roll formed into a wide range of elements for applications in the industrial, architectural, and transportation fields. Grade 316 also has outstanding welding characteristics. Post-weld annealing just isn’t required when welding thin sections. Ferralium® 255 weld wire is produced to enhance our main super duplex stainless-steel. Hiduron® 191 is a medium-power precipitation hardened cupronickel alloy provided in the hot labored situation.

Super Duplex Tube Fittings

It achieves larger strengths than most different stainless steels and alternative corrosion resistant alloys, providing the potential to scale back section measurement and due to this fact weight and cost. Alloy 825 is a nickel-iron-chromium alloy with additions of molybdenum, copper and titanium (NiCr21Mo). Langley Alloys can provide the distinctive steel in the hot worked and annealed situation. It achieves good mechanical properties from cryogenic to medium-high temperatures (5400C) and can be considerably strengthened via cold working.

We have thousands tons stock of stainless steel sheet and coil with various size and grade,mainly include austenitic stainless steel, martens stainless steel (including precipitation hardened stainless steel sheet & coil), ferritic stainless steel, and duplex stainless steel.

Characteristics of Stainless Steel Sheet and Plate:

High corrosion resistance

High strength

High toughness and impact resistance

Temperature resistance

High workability, including machining, stamping, fabricating and welding

Smooth surface finish that can be easily clean