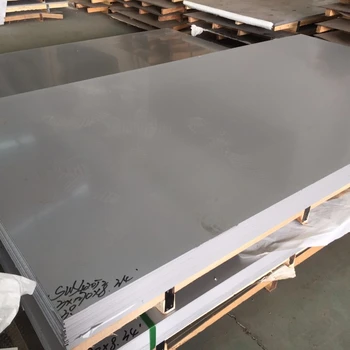

1.4016 aisi 430 stainless steel supplier

We produce ASTM/ASME Grade 304, Grade 304L,304h, 316, 316L, 316H, 316TI, 321, 321H, 309S, 309H, 310S, 310H, 410S, 2205, 904L, 2507, 254, gh3030, 625, 253MA, S30815, 317L, Type 317, 316lN, 8020, 800, 800H, C276, S32304 and others special requirement stainless steel grade.

Content

For instance, when combining 420 to 304 quality stainless welding, it’s essential to be extra careful and attentive. By using 1.4021(ASTM 420 – SS2303) you get a stainless and hardenable metal with high tensile power and good corrosion resistance. The steel has good machinability and is used for e.g. shafts, spindles, pump components and nuts.

Martensitic stainless steels are optimised for top hardness, and other properties are to some degree compromised. Fabrication should be by strategies that enable for poor weldability and normally additionally allow for a ultimate harden and mood warmth remedy. Corrosion resistance is lower than the widespread austenitic grades, and their helpful operating temperature vary is restricted by their loss of ductility at sub-zero temperatures and lack of energy by over-tempering at elevated temperatures. 420 grade stainless steels have high tensile energy after warmth treatment.

It shall not be utilized in marine or in chloride setting. The steel is magnetic and within the quenched and tempered situation. Martensitic chrome steel supposed for thermal enchancment, showing excessive mechanical properties – power, ductility and machinability, whereas sustaining enough corrosion resistance. 2H13 does not show resistance to chlorine, salts and intergranular corrosion.

Technique

The Development Of A Groundbreaking Perovskite Solar Cell

- Its finest corrosion resistance is achieved when the steel is hardened and floor ground or polished.

- AISI 420 chrome steel is an alloy of iron, further categorized as a martensitic stainless-steel.

- Additionally, the British Standard (BS) designation is 420S29.AISI Grade 420 chrome steel is a higher carbon version of 410.

- Fabrication must be by strategies that allow for poor weldability and often also permit for a final harden and temper heat remedy.

Stock Thickness: 0.1-200.0mm

Production thickness: 0.5.0-200mm

Width: 600-3900mm

Length: 1000-12000mm

Grade:

200 series: 201,202

300 series: 301,304,304L,304H,309,309S,310S,316L,316Ti,321,321H,330

400 series: 409,409l,410,420J1,420J2,430,436,439,440A/B/C

Duplex: 329,2205,2507,904L,2304

Surface: No.1,1D,2D,2B,NO.4/4K/hairline,satin,6k,BA,mirror/8K

Best machinability is within the sub-crucial annealed situation. 1.4021 is possible to weld and shall be welded with welding consumables just like that of the parent one.

Under regular situations, this material has an average corrosion resistance. 420 is included within the martensitic stainless-steel group.

The martensitic steels should be preheated to temperatures above MS usually ( ºC). The warmth enter should not be too excessive or too low (zero.5-1.5 kJ/mm).

Those who don’t want to take care of warmth remedy and those who want a strong mechanical feature can prefer 431 high quality or 630 grade stainless-steel. 420 (1.4021) grade stainless steel material has a excessive surface hardness after warmth therapy and the heat treated materials is proof against friction. In spite of the high carbon content material, 420 grade stainless steel supplies have an excellent workability.

We have thousands tons stock of stainless steel sheet and coil with various size and grade,mainly include austenitic stainless steel, martens stainless steel (including precipitation hardened stainless steel sheet & coil), ferritic stainless steel, and duplex stainless steel.

Characteristics of Stainless Steel Sheet and Plate:

High corrosion resistance

High strength

High toughness and impact resistance

Temperature resistance

High workability, including machining, stamping, fabricating and welding

Smooth surface finish that can be easily clean